Patents

Literature

31results about How to "Improve display life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

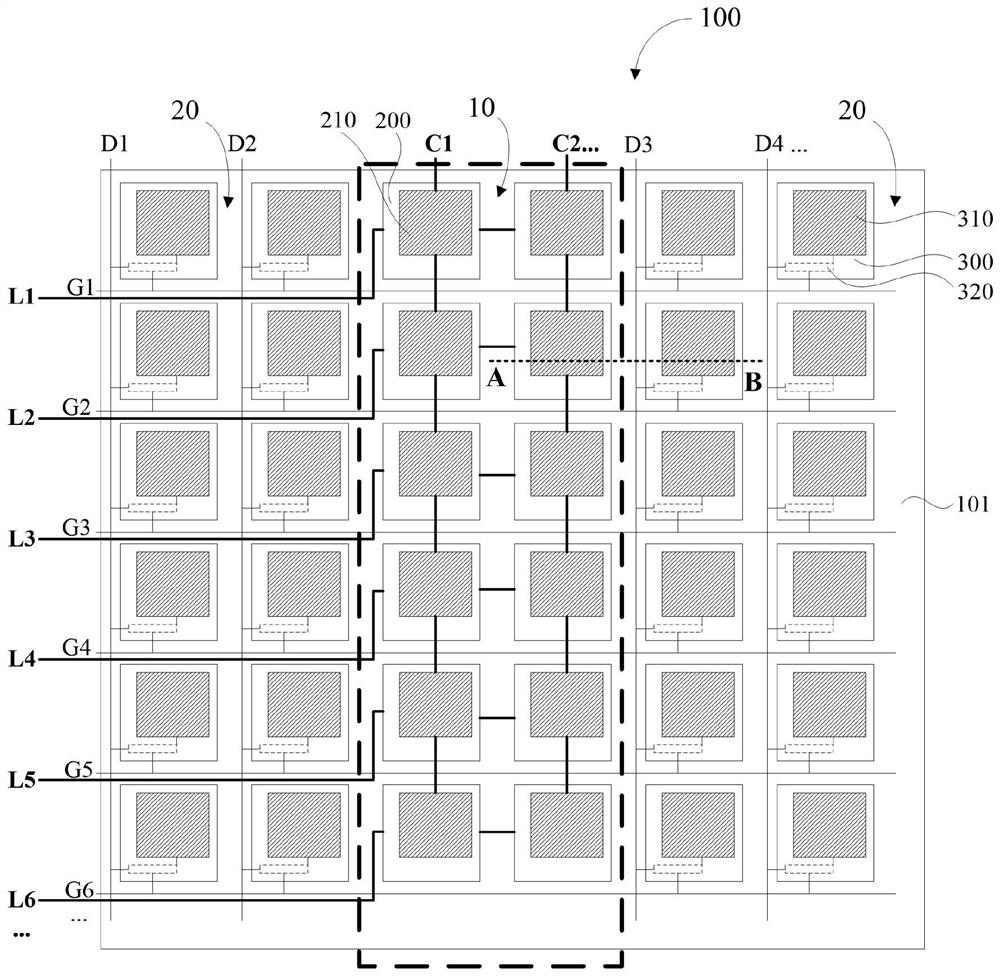

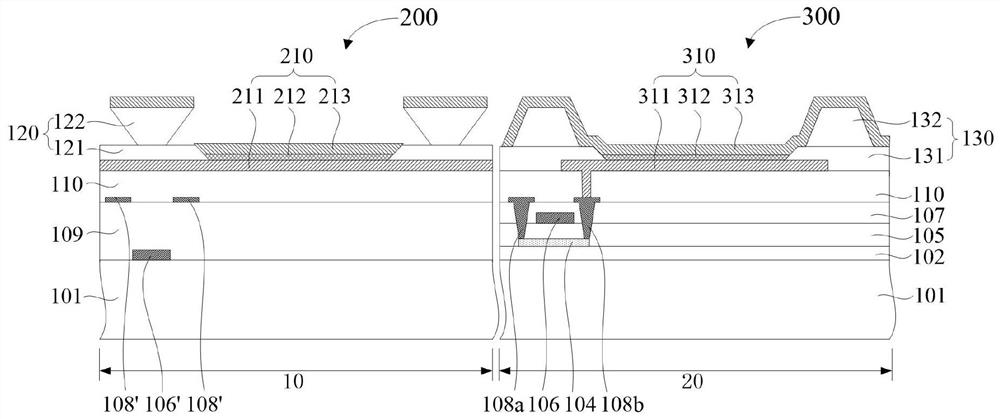

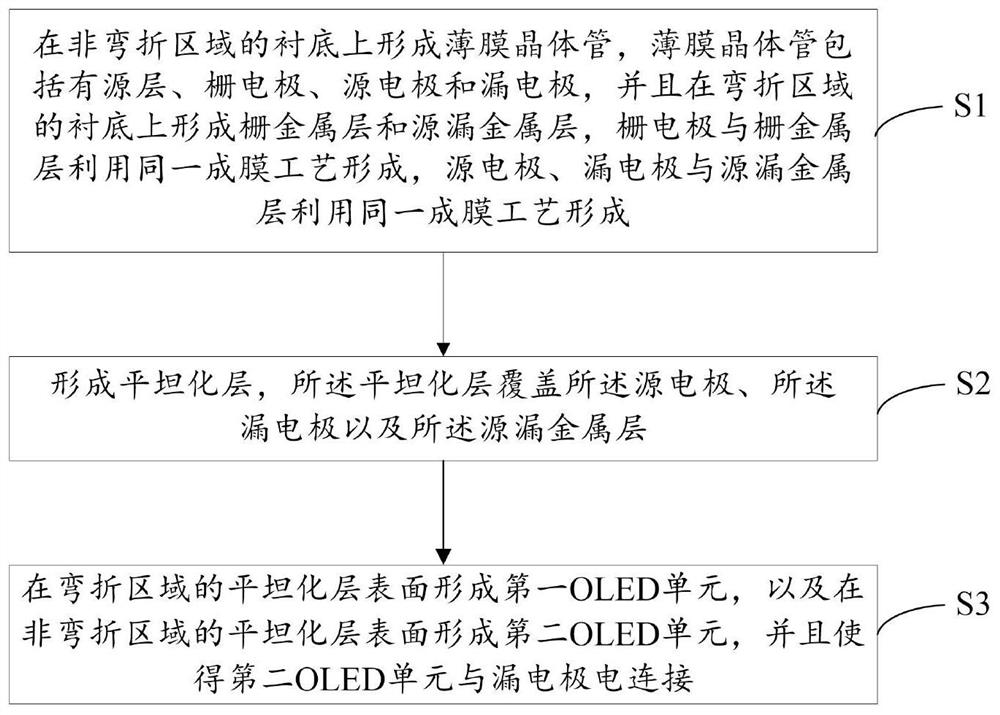

Display substrate and manufacturing method thereof, and display apparatus

ActiveCN108269835ALuminous effectAvoid showing performance changesSolid-state devicesSemiconductor devicesEngineeringInorganic materials

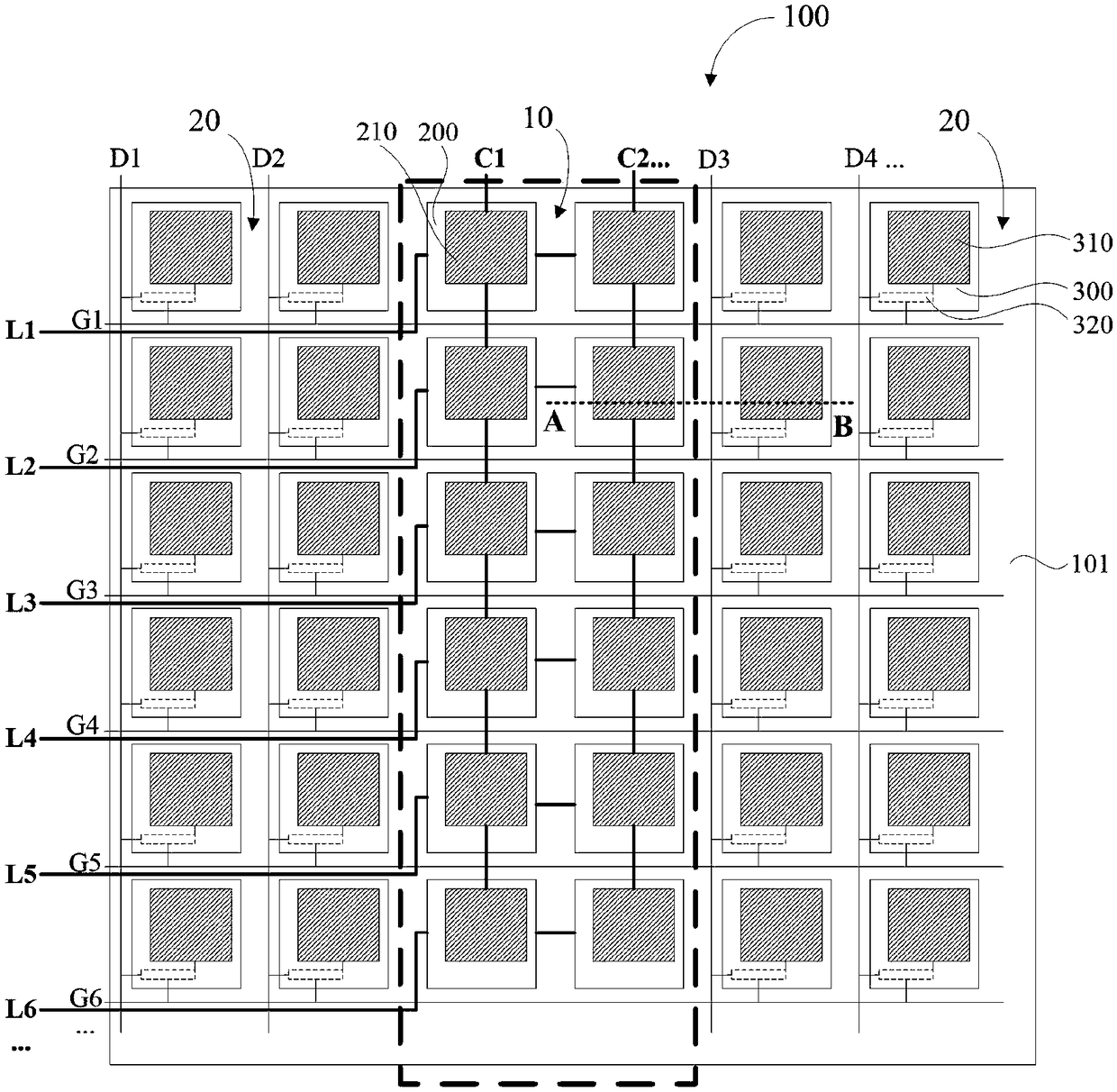

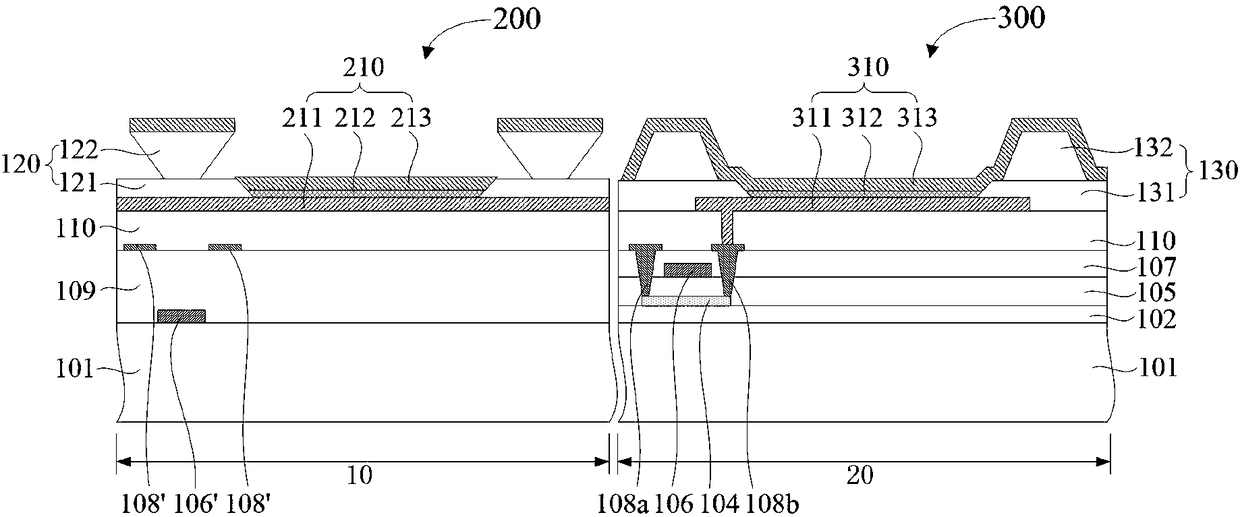

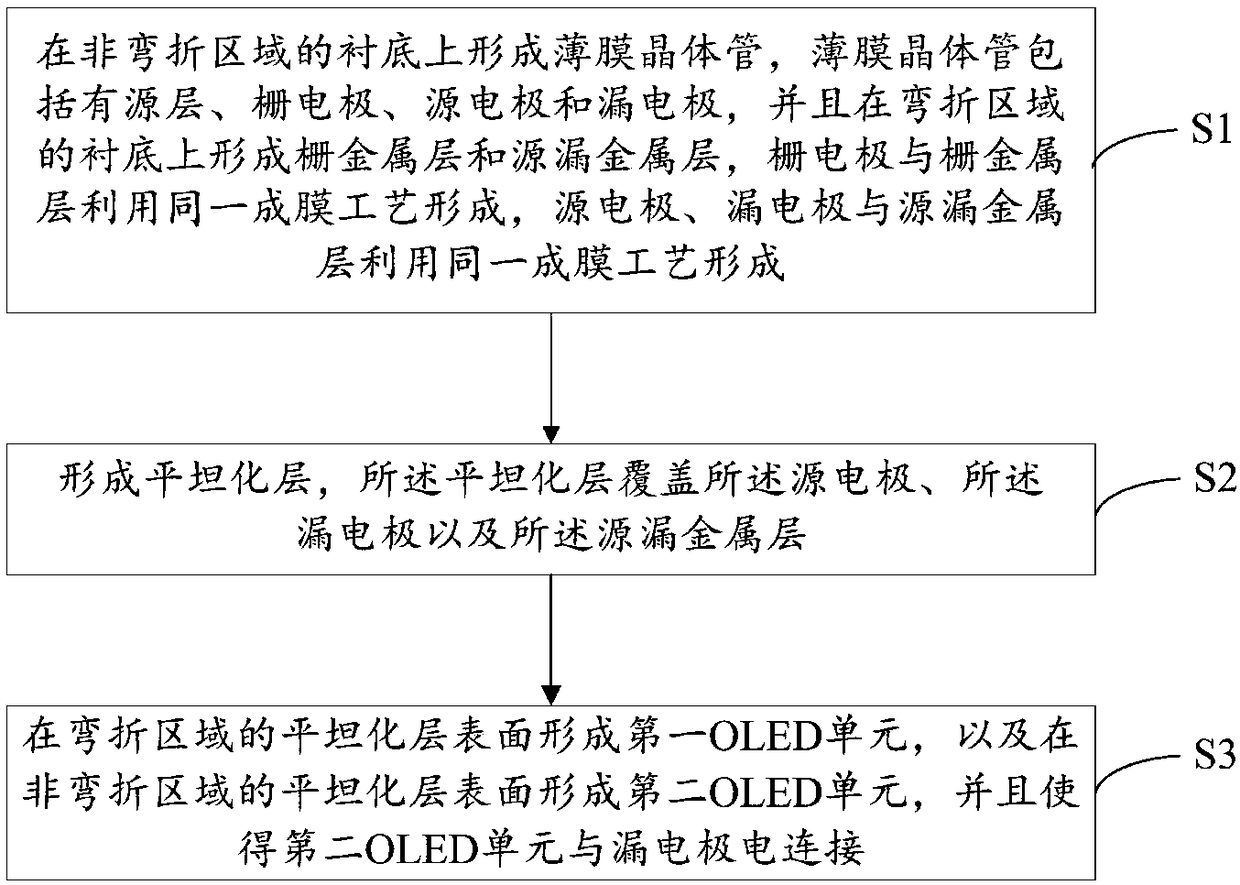

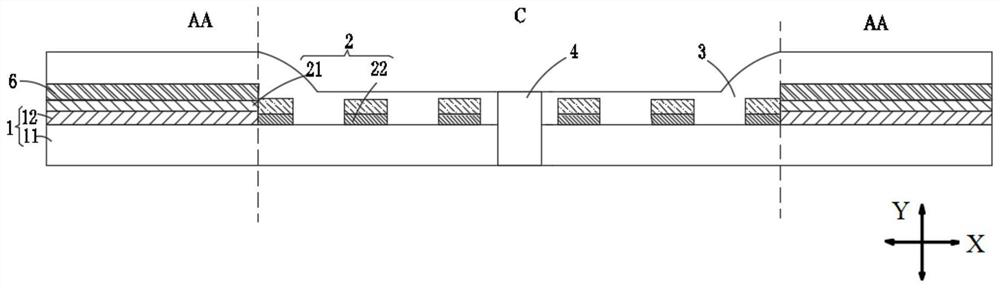

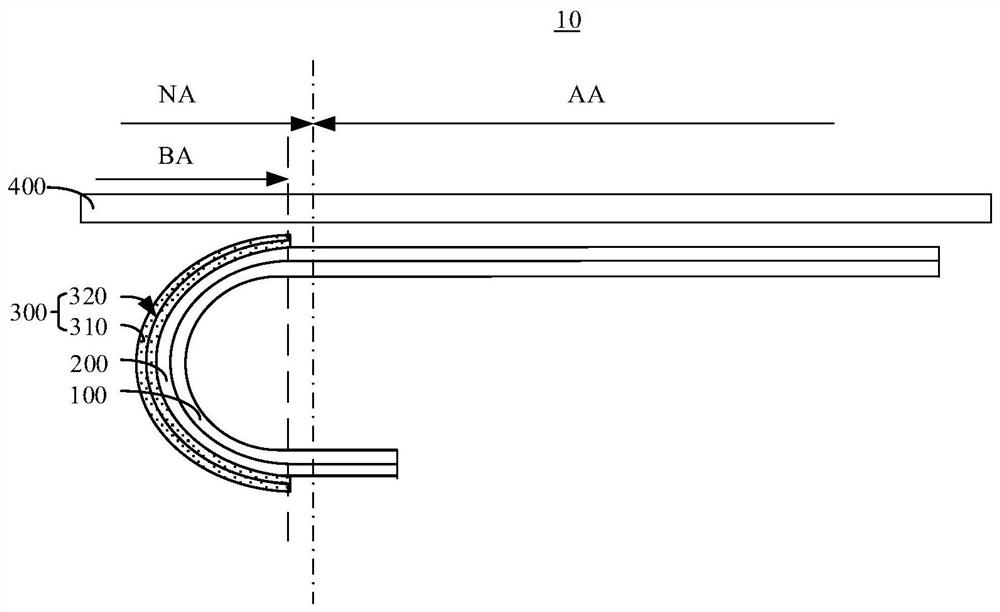

The invention provides a display substrate and a manufacturing method thereof, and a display apparatus. The display substrate comprises a display region on a substrate; a bending region in the displayregion comprises at least one PMOLED; the PMOLED is not driven by a thin film transistor, so that influence to the display performance caused by electrical performance change due to bending of the thin film transistor can be avoided effectively; furthermore, an organic insulating layer is included between the substrate and a first OLED unit; and the organic insulating layer comprises an organic material. Compared with an inorganic material, the organic material has high strain elasticity, so that the bending resistance of the bending region can be improved; and by adoption of the manufacturing method of the display substrate provided by the invention, the display service life of the display region can be prolonged effectively. According to the display apparatus comprising the display substrate provided by the invention, the bending region in the display region comprises at least one PMOLED, so that display performance change caused by bending of the thin film transistor can be avoided.

Owner:YUNGU GUAN TECH CO LTD

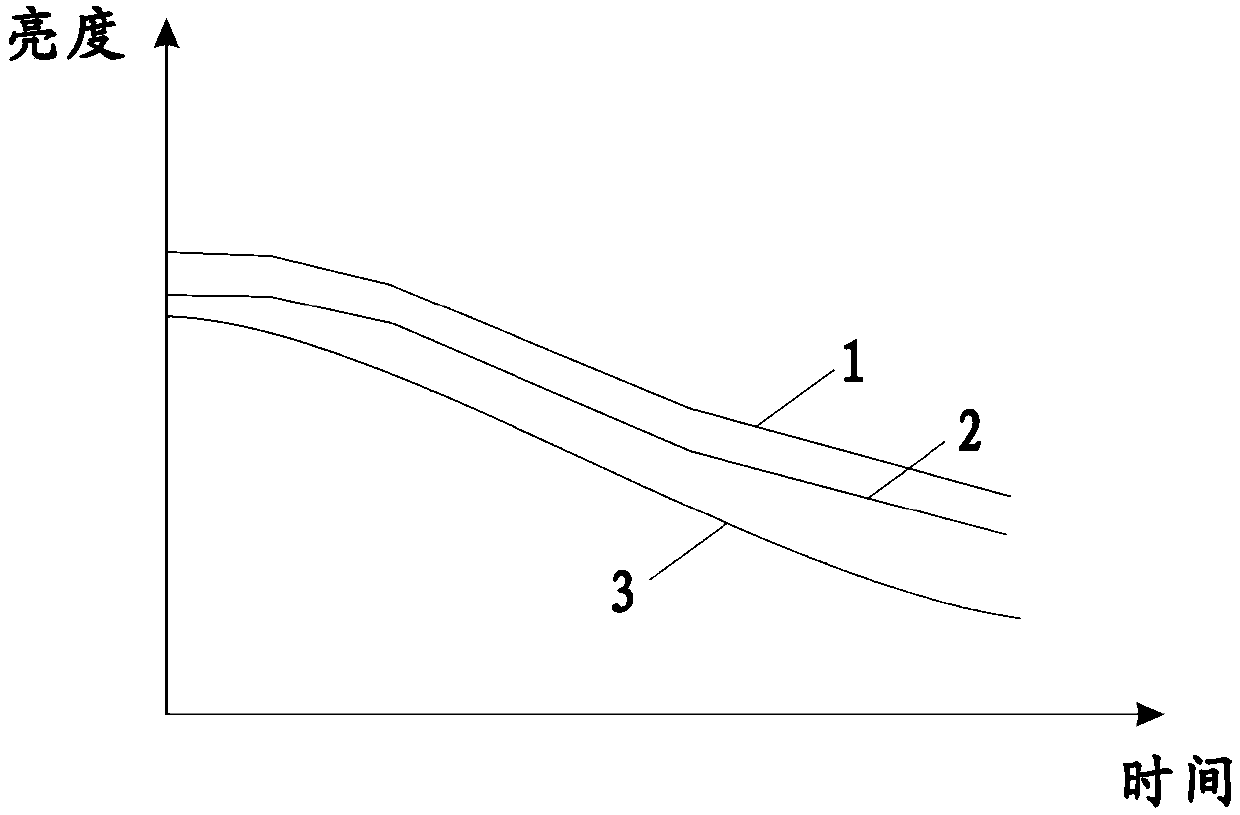

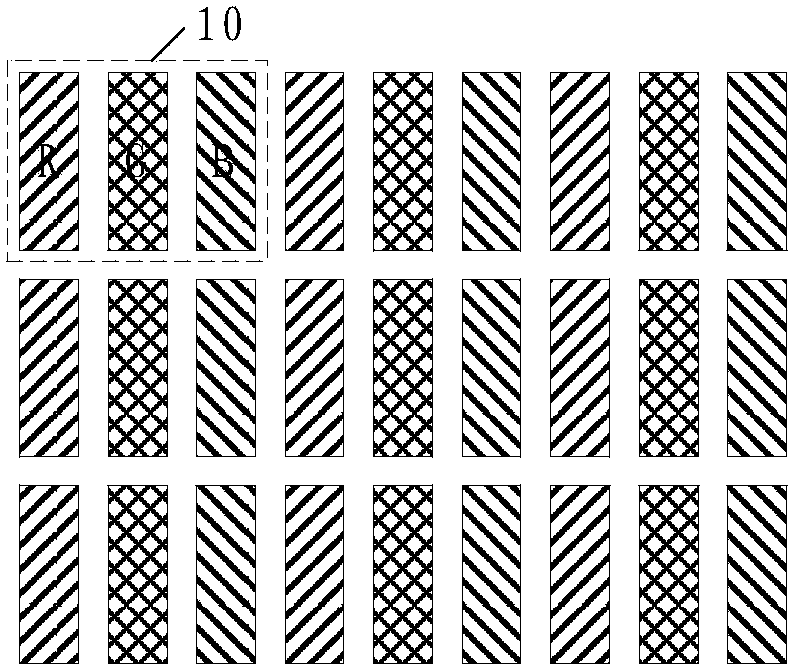

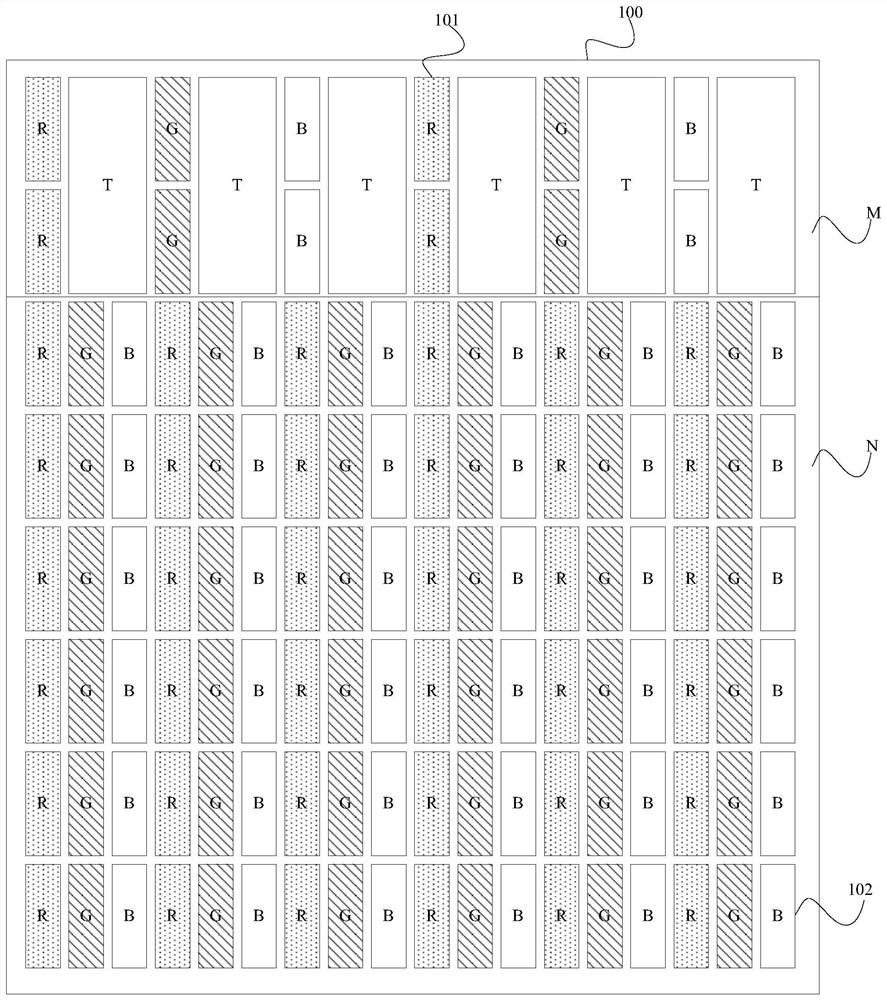

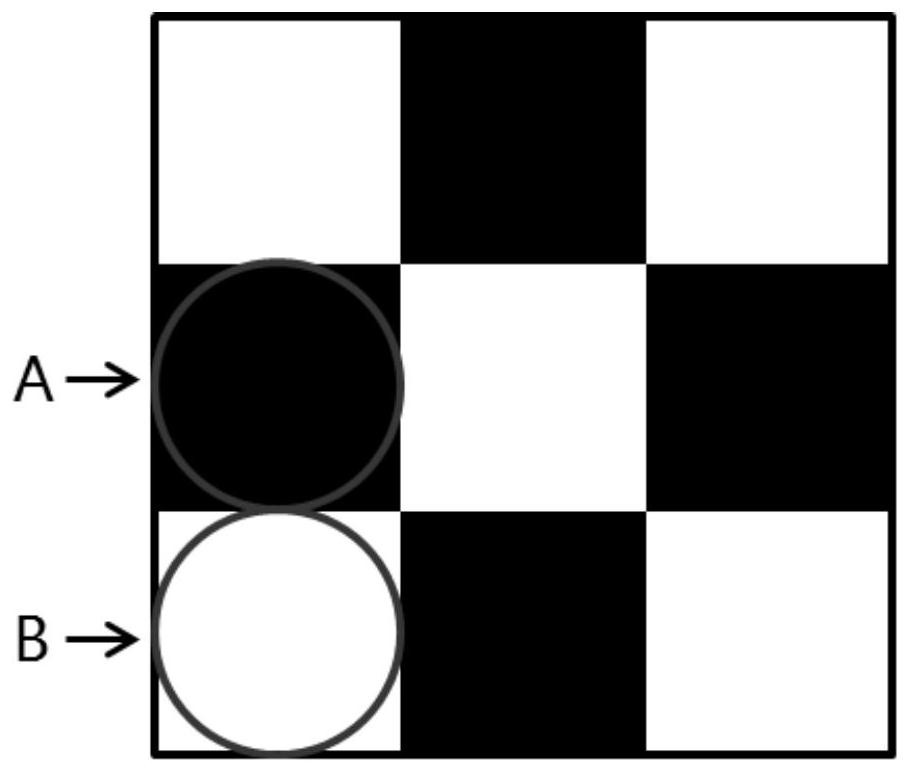

OELD (Organic Electron Luminescence) display device and display method thereof

ActiveCN103745688ASmall attenuationFast decayStatic indicating devicesDisplay deviceOrganic electroluminescence

The invention provides an OELD (Organic Electron Luminescence) display device and a display method thereof and relates to the technical field of display, and the display device can be used for solving the problem that subpixels in different colors of an existing display device are different in decay rate along with different display time, and thus the display white balance of the display device is subjected to red deviation. According to the display method of the OELD display device, each pixel unit of the display device at least comprises subpixels with red, green and blue base colors. The method comprises the following steps: when each pixel unit in a first region of a display image only drives and lightens the blue subpixel, reducing a corresponding gray-scale value of the blue subpixel of the first region; and / or when each pixel unit in a second region of the display image only drives and lightens the red subpixel, improving a corresponding gray-scale value of the red subpixel of the second region; and / or when each pixel unit in a third region of the display image only drives and lightens the green subpixel, improving a corresponding gray-scale value of the green subpixel of the third region.

Owner:HISENSE VISUAL TECH CO LTD

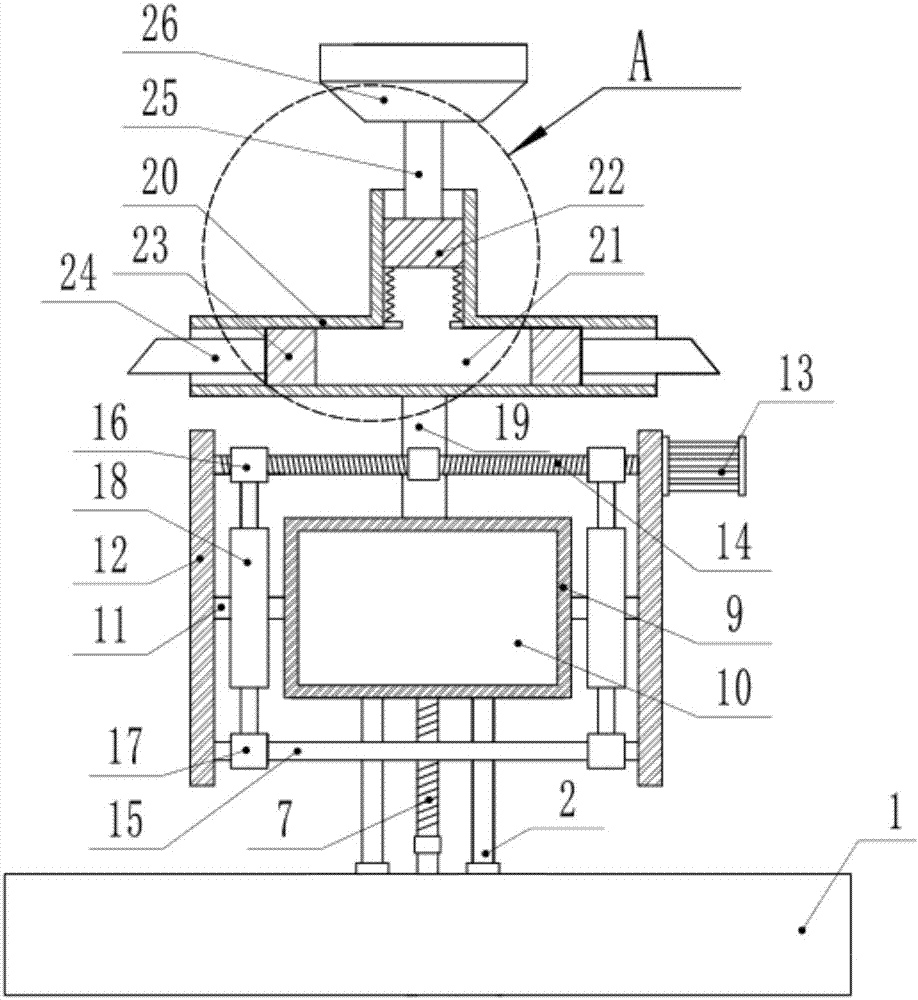

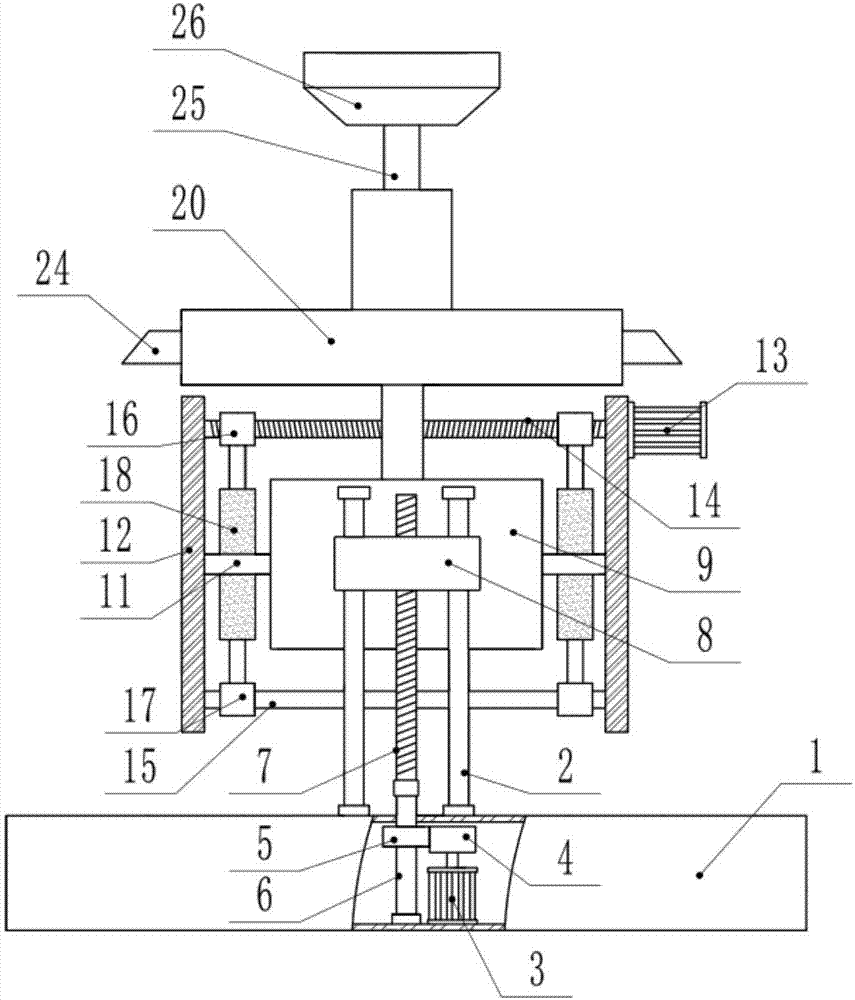

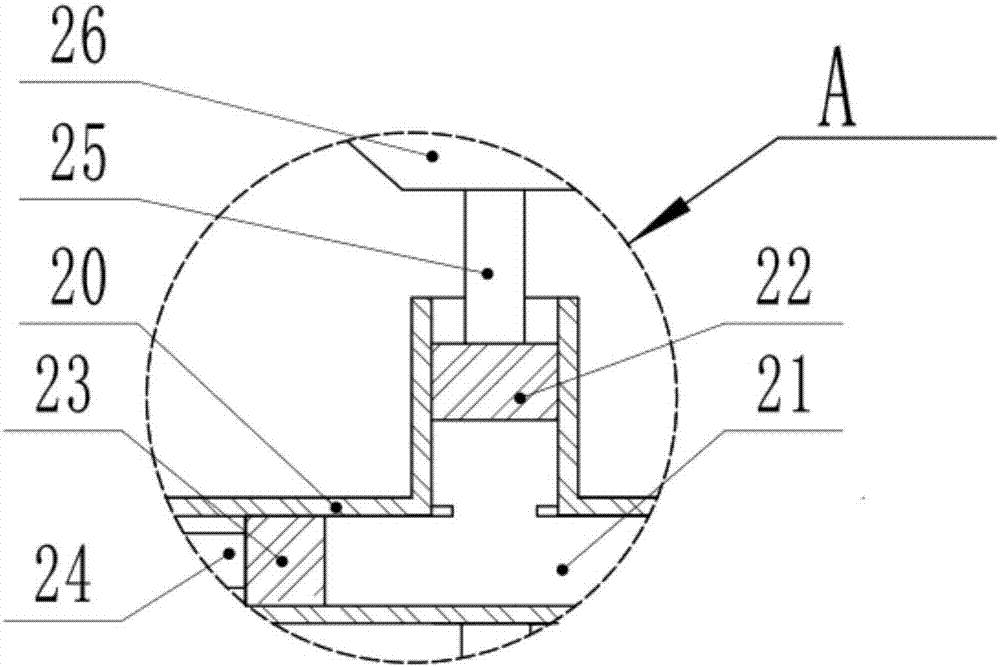

Outdoor advertising display screen facilitating dust removal

InactiveCN107393417AFree height adjustmentImprove display lifeCleaning using toolsIdentification meansFixed frameDrive motor

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

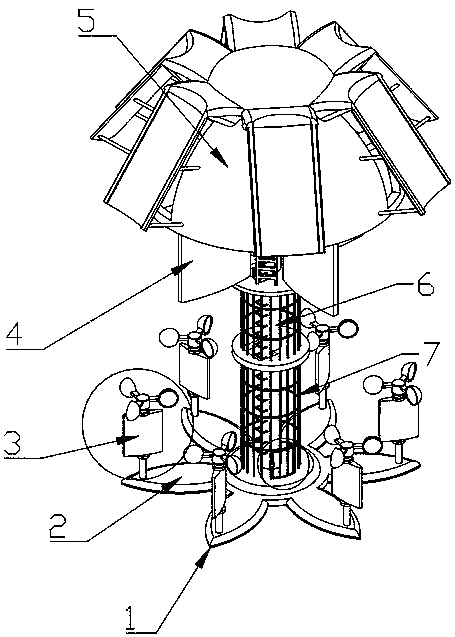

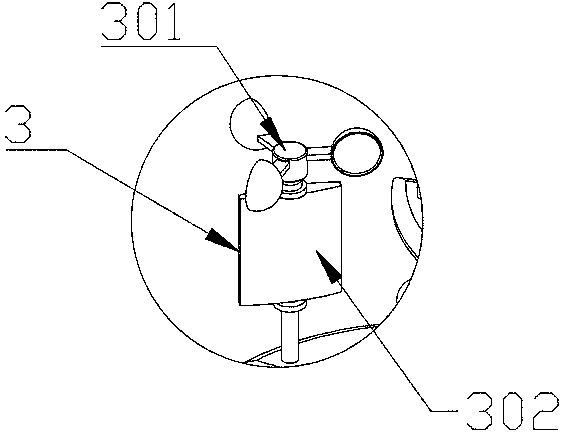

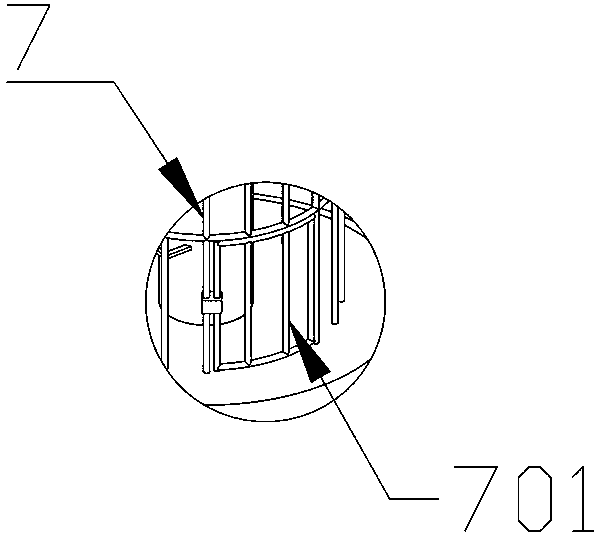

Rotary advertising board

InactiveCN108597410AImprove advertising effectivenessImprove display effectBoardsEngineeringWind power

The invention provides a rotary advertising board which comprises bottom advertising boards, upper advertising boards and a rainproof shed roof, wherein each bottom advertising board is formed by a wind-power rotary bowl and an advertisement showing board, a supporting column is arranged at the middle position of a base, a standing platform is arranged on a protection cage and the supporting column, the rainproof shed roof is fixedly arranged on the top side of the supporting column, the upper advertising boards are of a cross structure and are symmetrically fixed between the rainproof shed roof and the standing platform at the upper end of the rainproof shed roof, and top climbing ladders are arranged among the upper advertizing boards. The rotary advertizing board is provided with the wind-power rotary bowls which are arranged at the upper ends of the advertisement showing boards; furthermore, the wind-power rotary bowls and the advertisement showing boards are connected through differential gears, so that the wind-power rotary bowls are favorable for being driven by wine to rotate, and the advertisement showing boards on the lower side can be driven to rotate; in addition, the rotating speeds of the advertisement showing boards are reduced by arranging the differential gears, and a display effect is improved.

Owner:BINZHOU UNIV

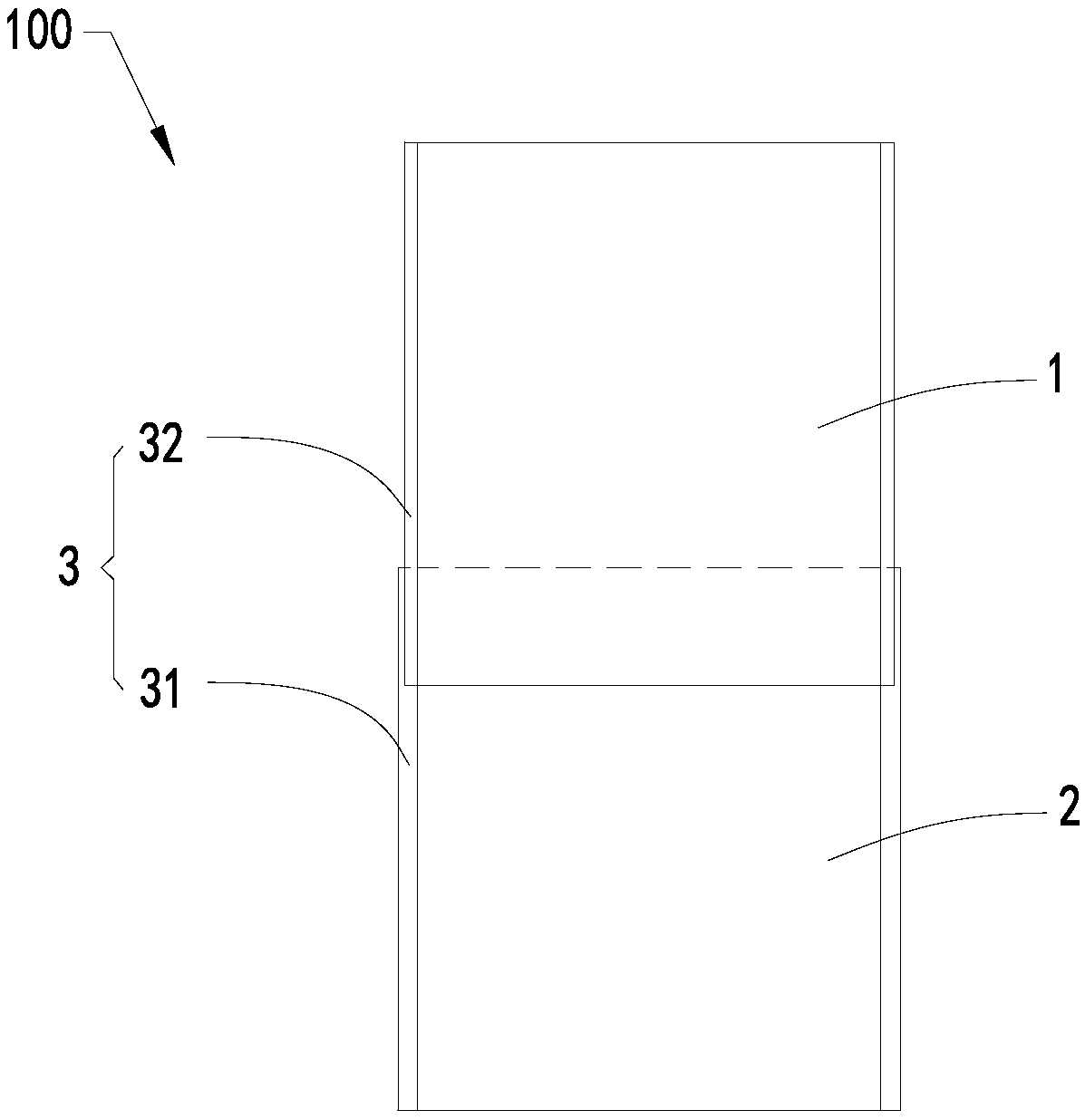

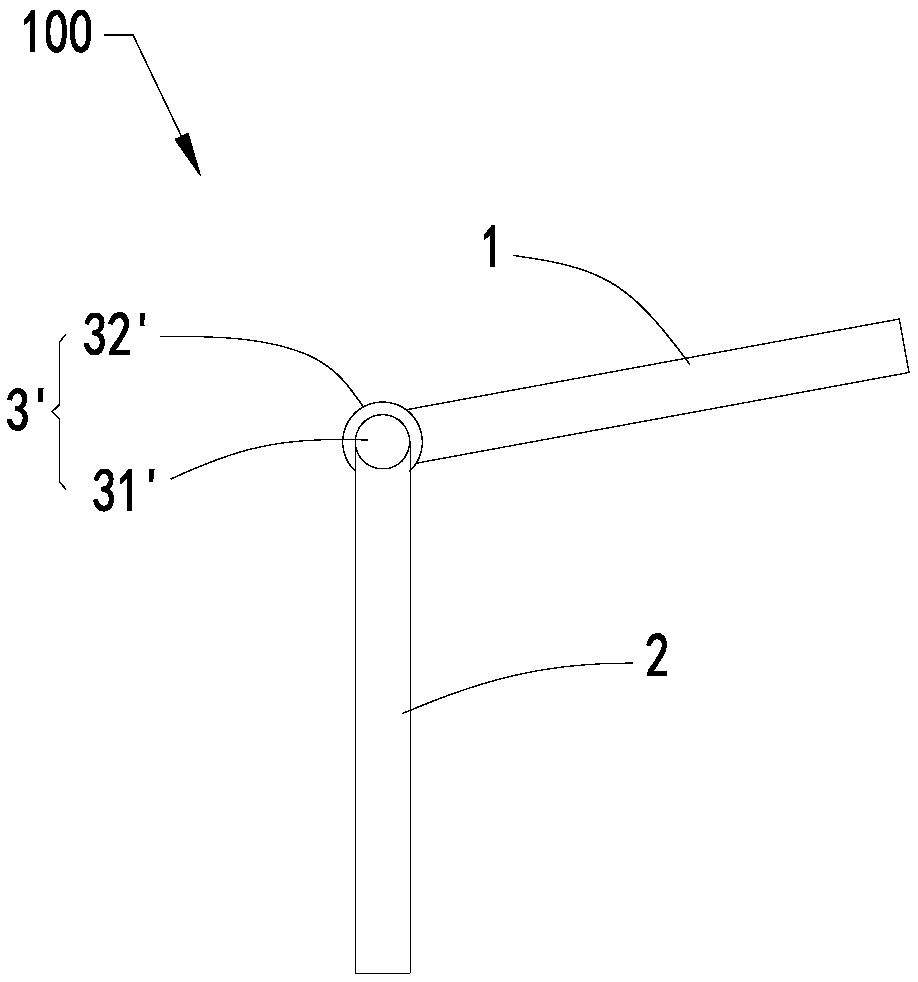

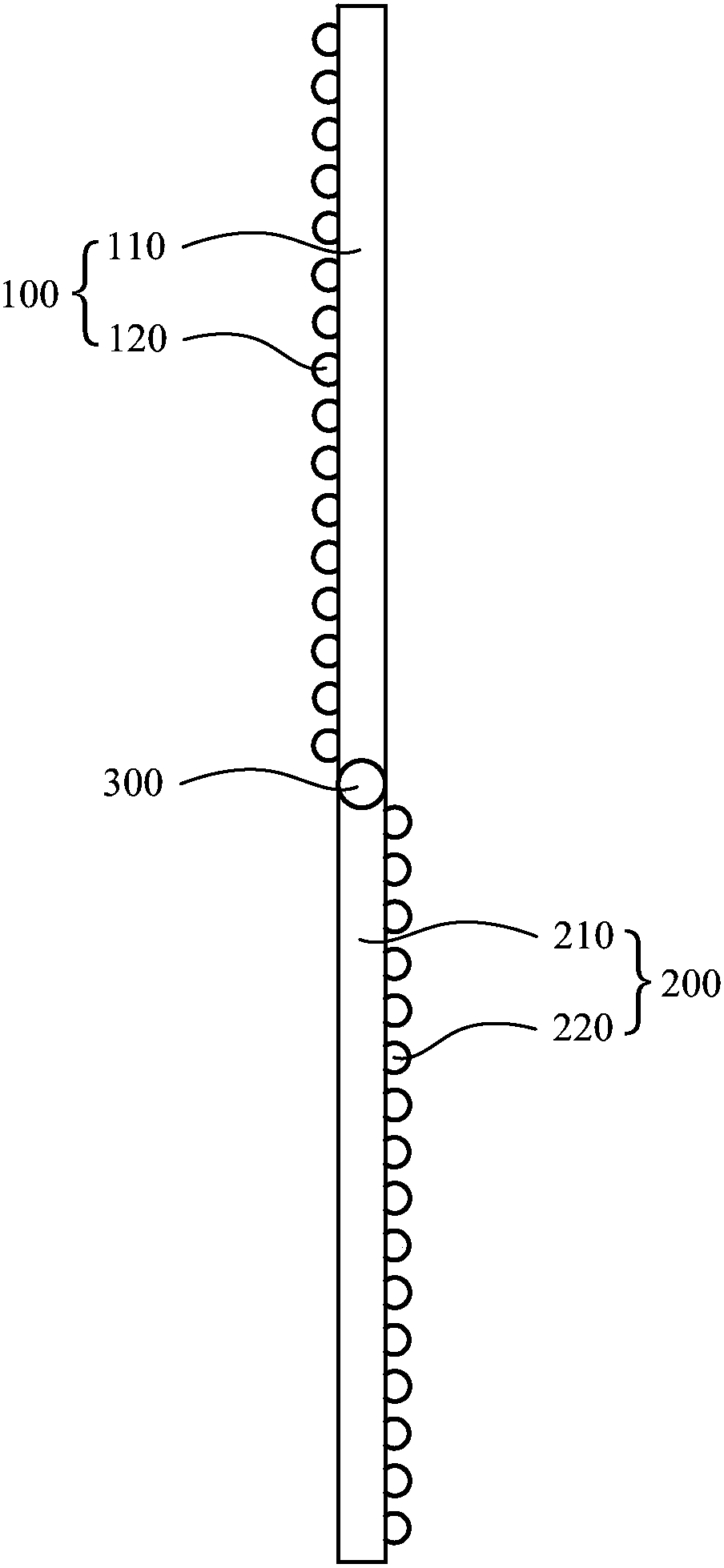

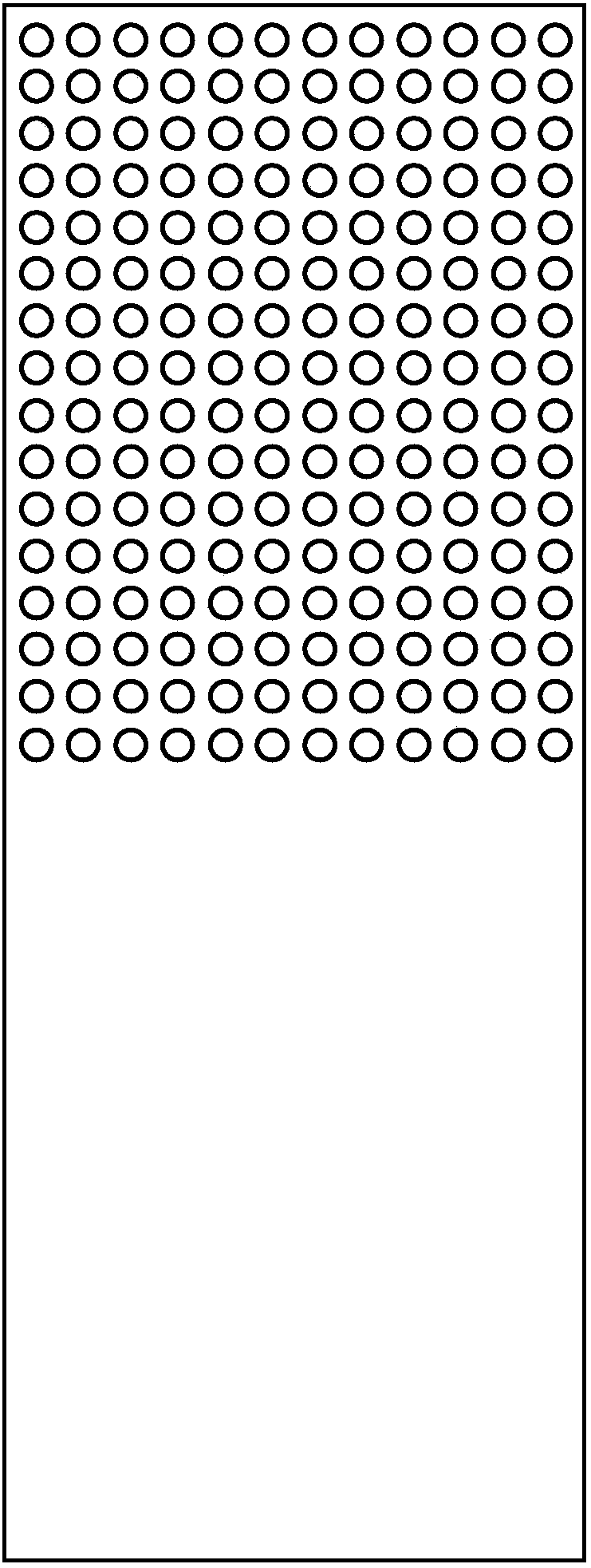

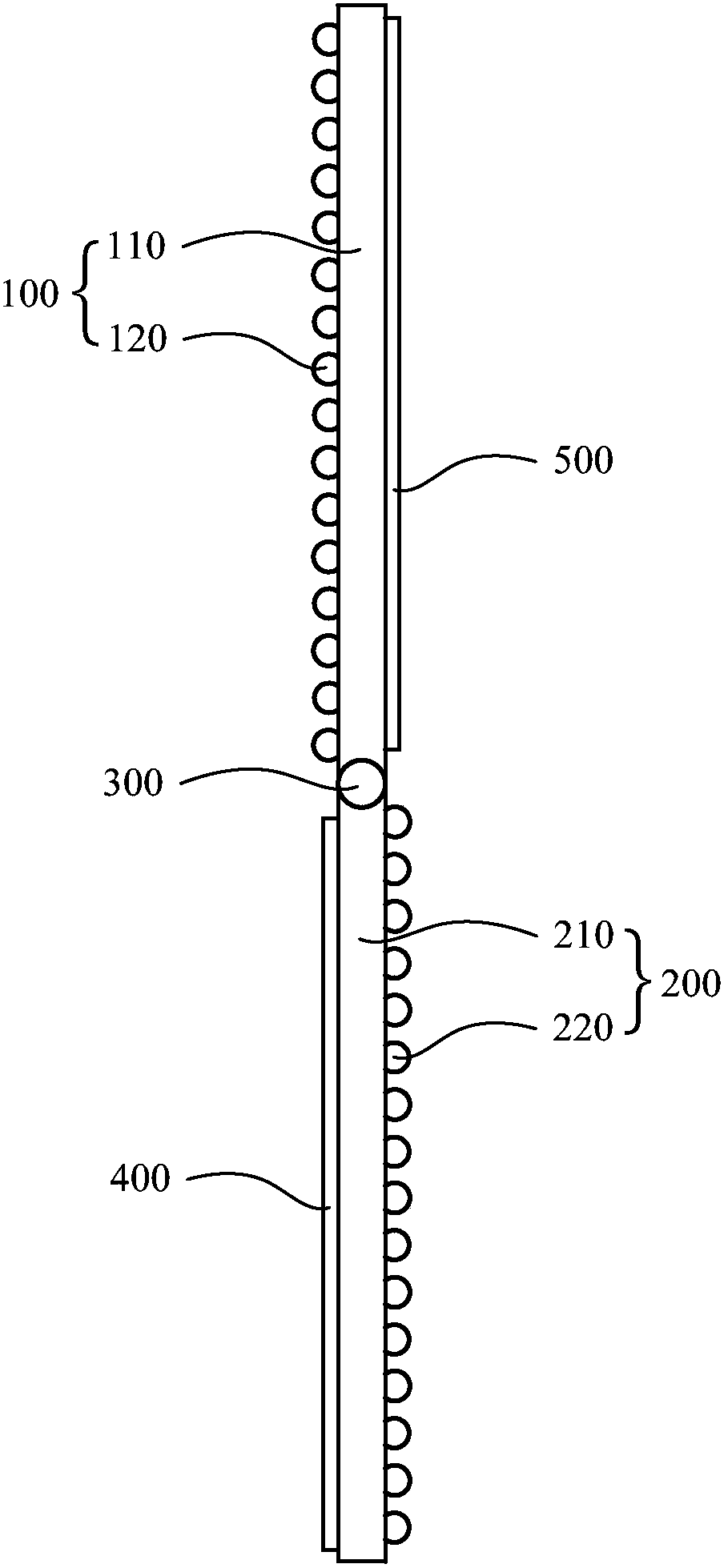

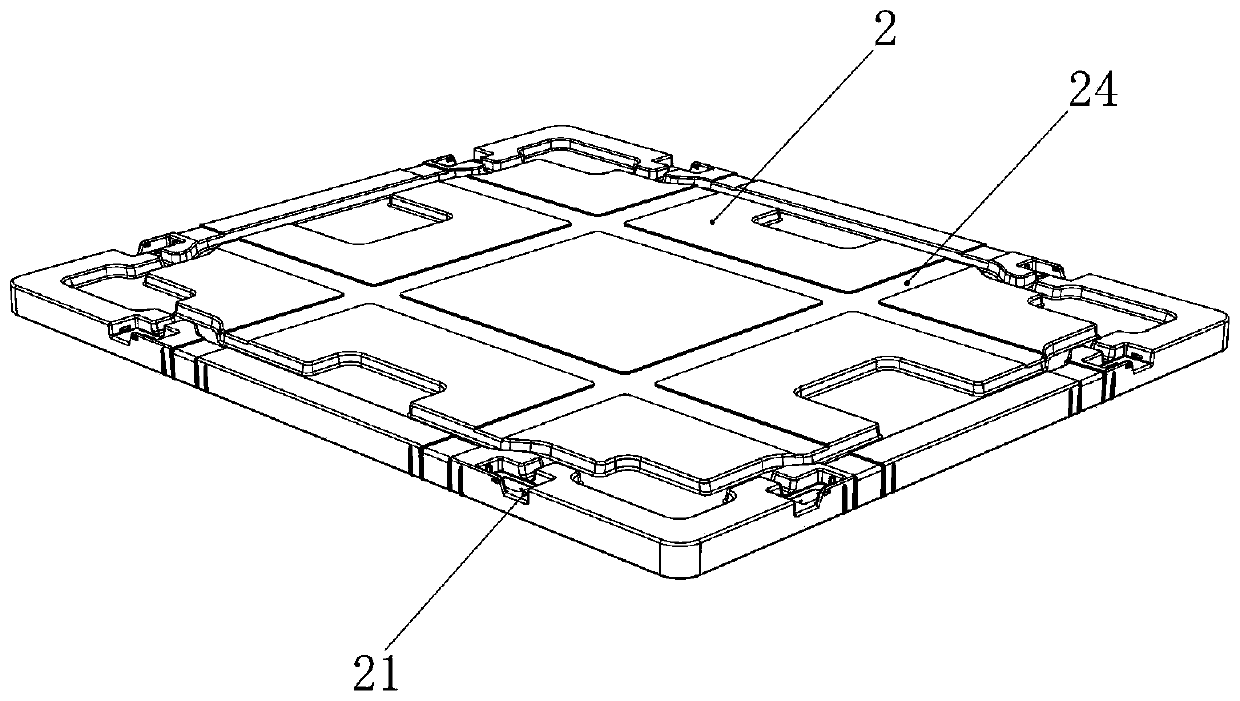

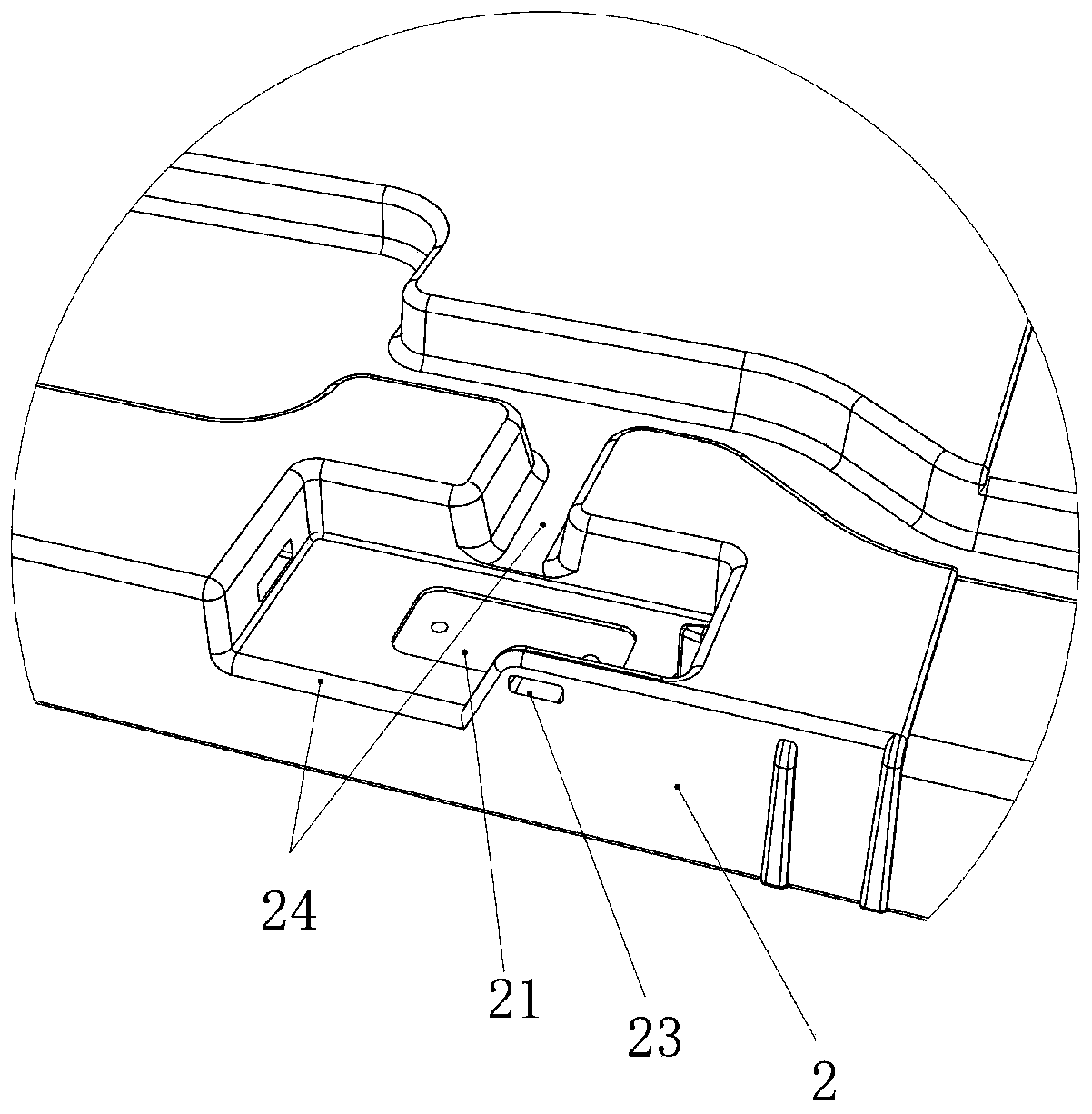

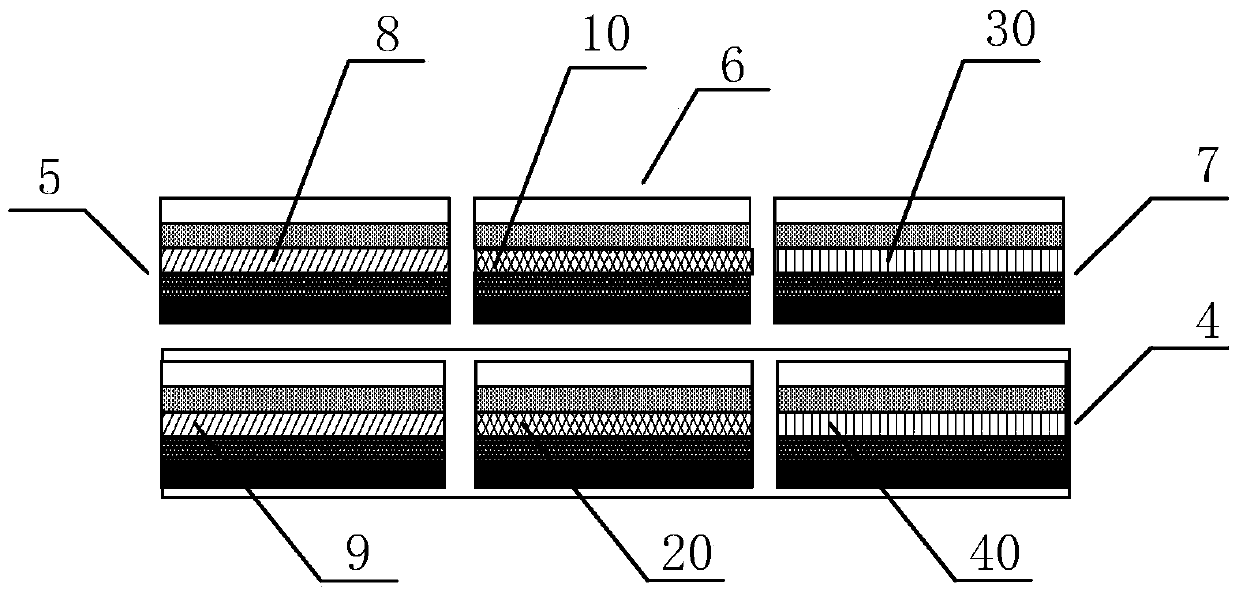

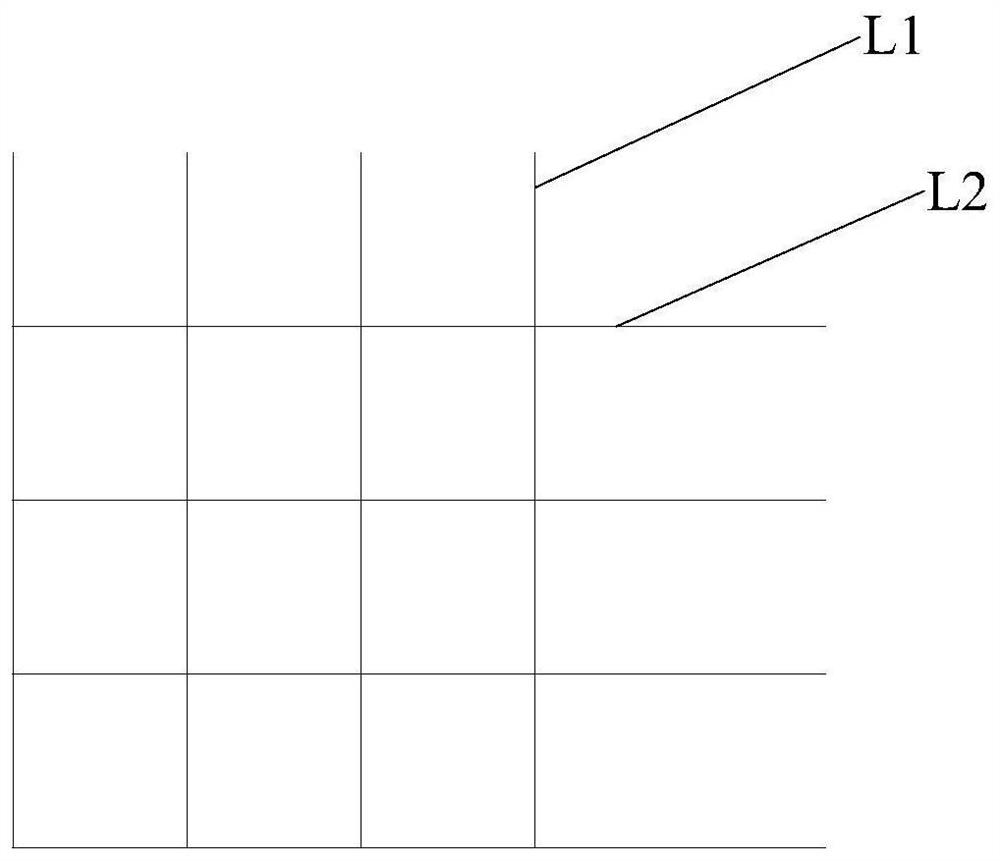

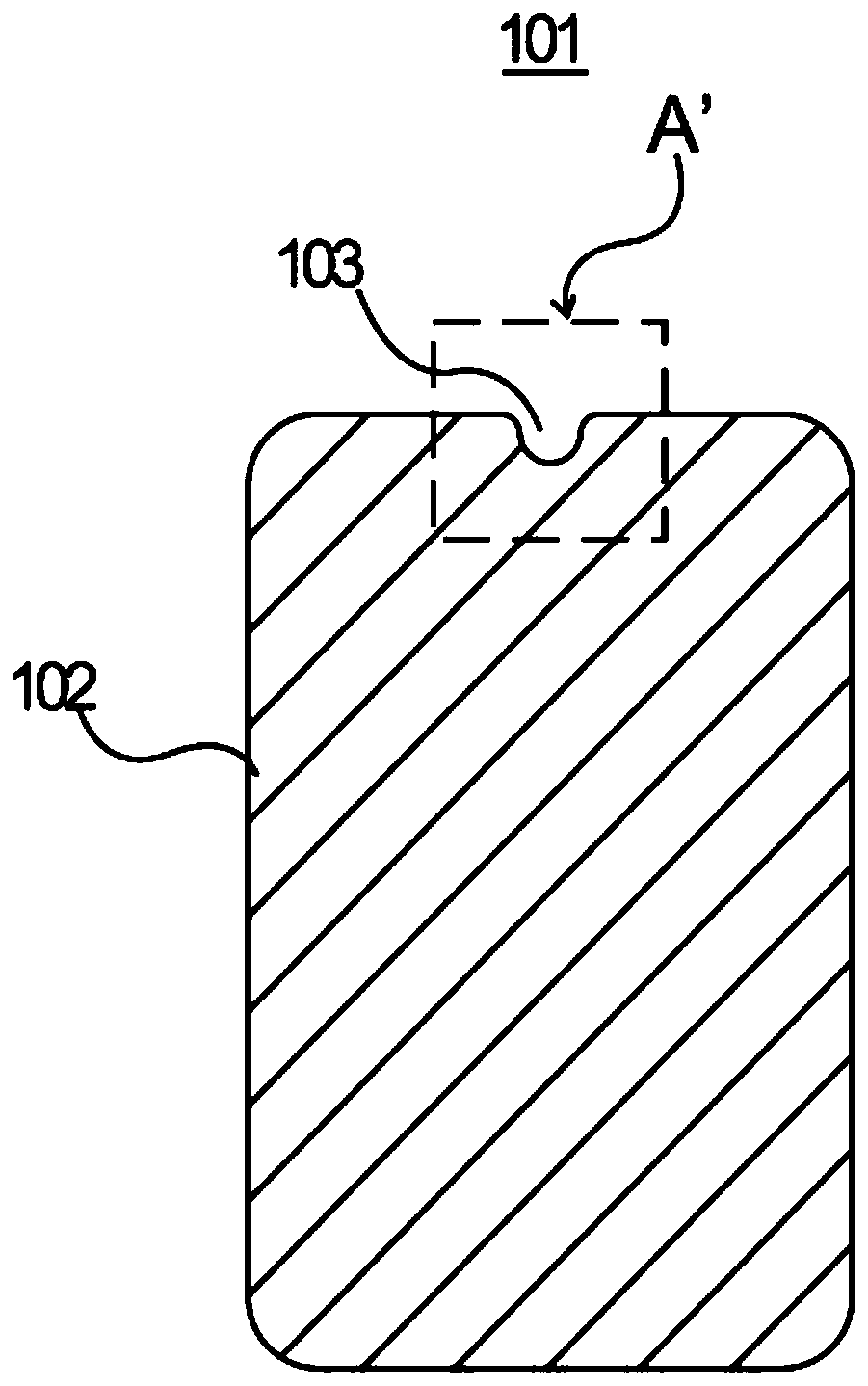

Supporting assembly and flexible display module

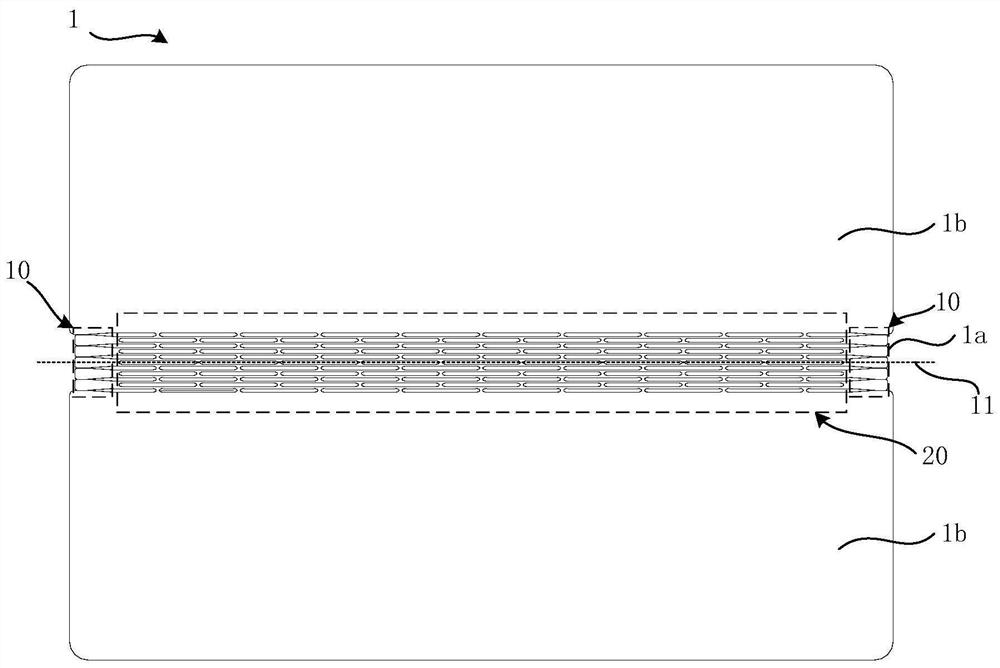

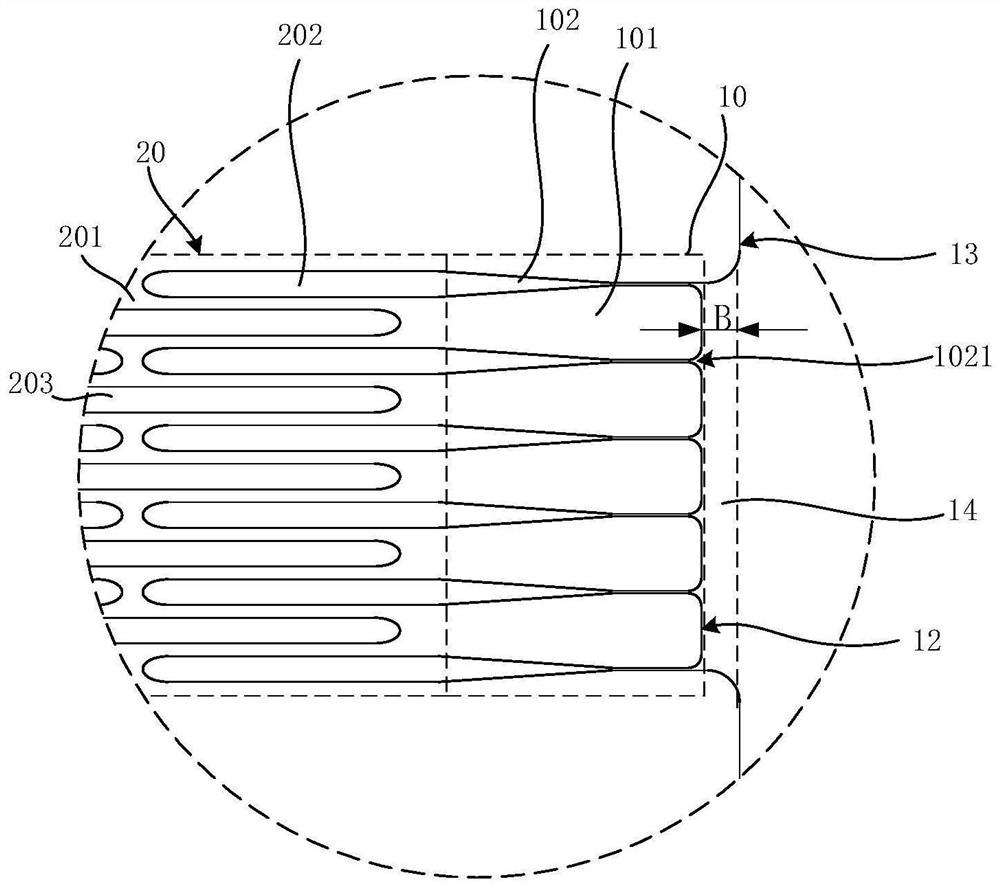

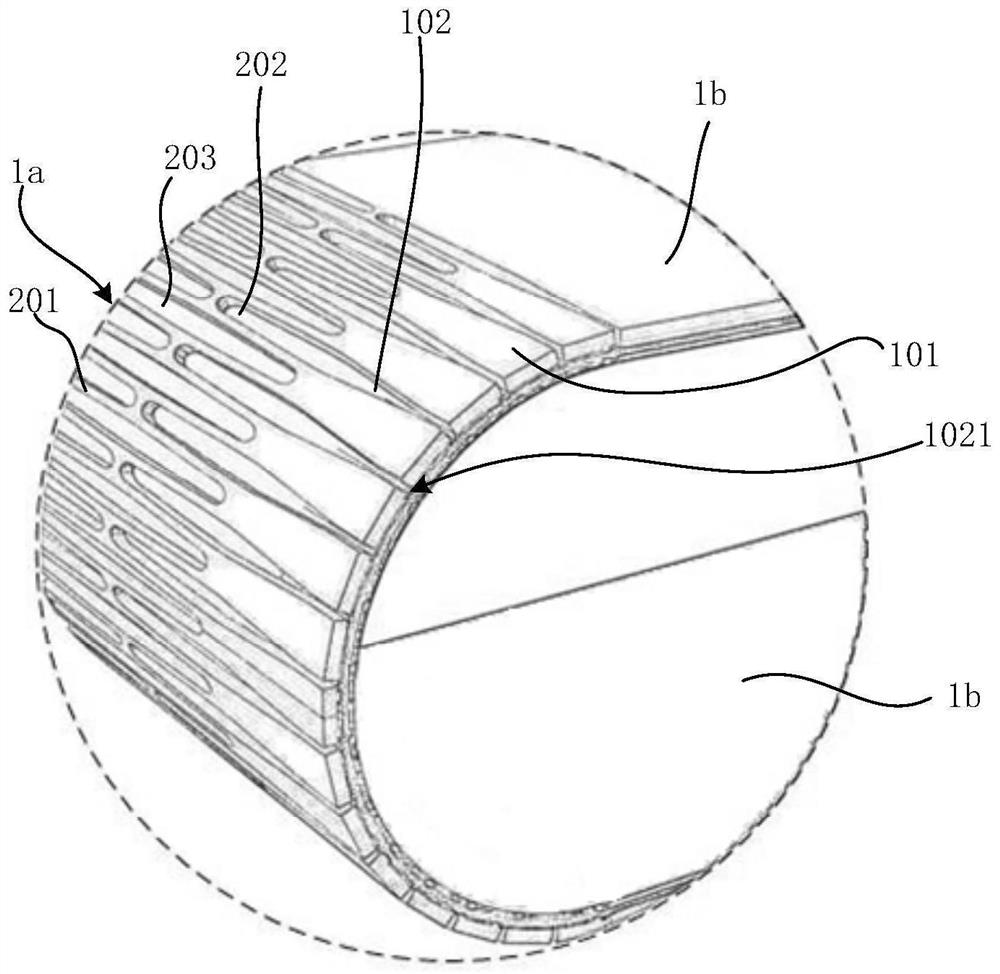

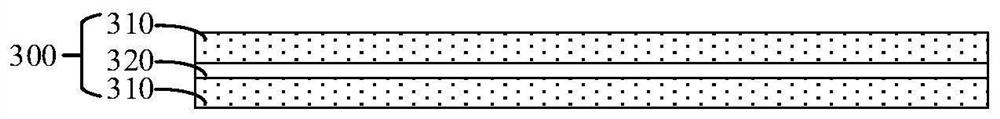

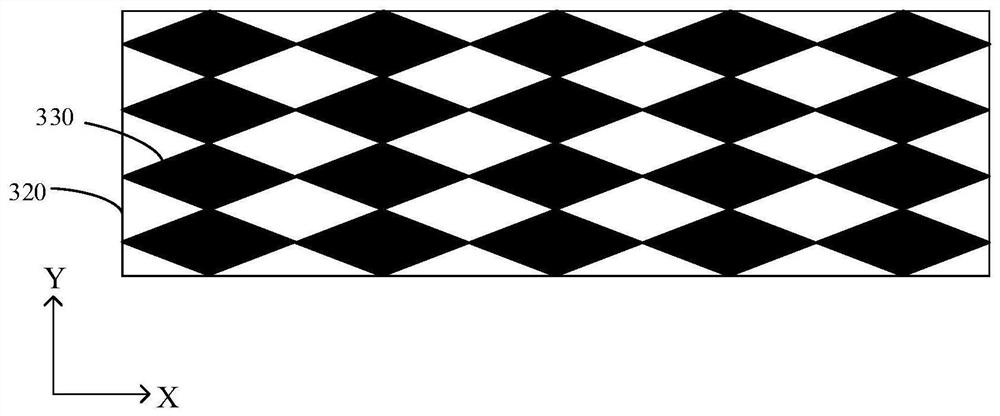

ActiveCN113539102AImprove display lifeReduce the probability of intrusion into the flexible display modulePhotovoltaic energy generationIdentification meansWater vaporEngineering

The invention discloses a supporting assembly and a flexible display module. The supporting assembly comprises a supporting layer, the supporting layer is of a patterned structure in a bending area, the patterned structure comprises two first edges perpendicular to a bending axis of the bending area, the patterned structure comprises two first hollow-out patterns respectively arranged at the first edges, each first hollow-out pattern comprises a plurality of supporting blocks and a plurality of first hollow-out parts, the supporting blocks are arranged in the direction perpendicular to the bending axis, each first hollow-out part is located between every two adjacent supporting blocks, and a notch is formed in the position, close to the adjacent first edge, of each first hollow-out part. When the supporting layer is in the bending state, the notch shrinks to the closed state, so that the probability that water vapor and dust invade into the flexible display module when the flexible display module is in the bent state is reduced, and the display life of the flexible display module is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

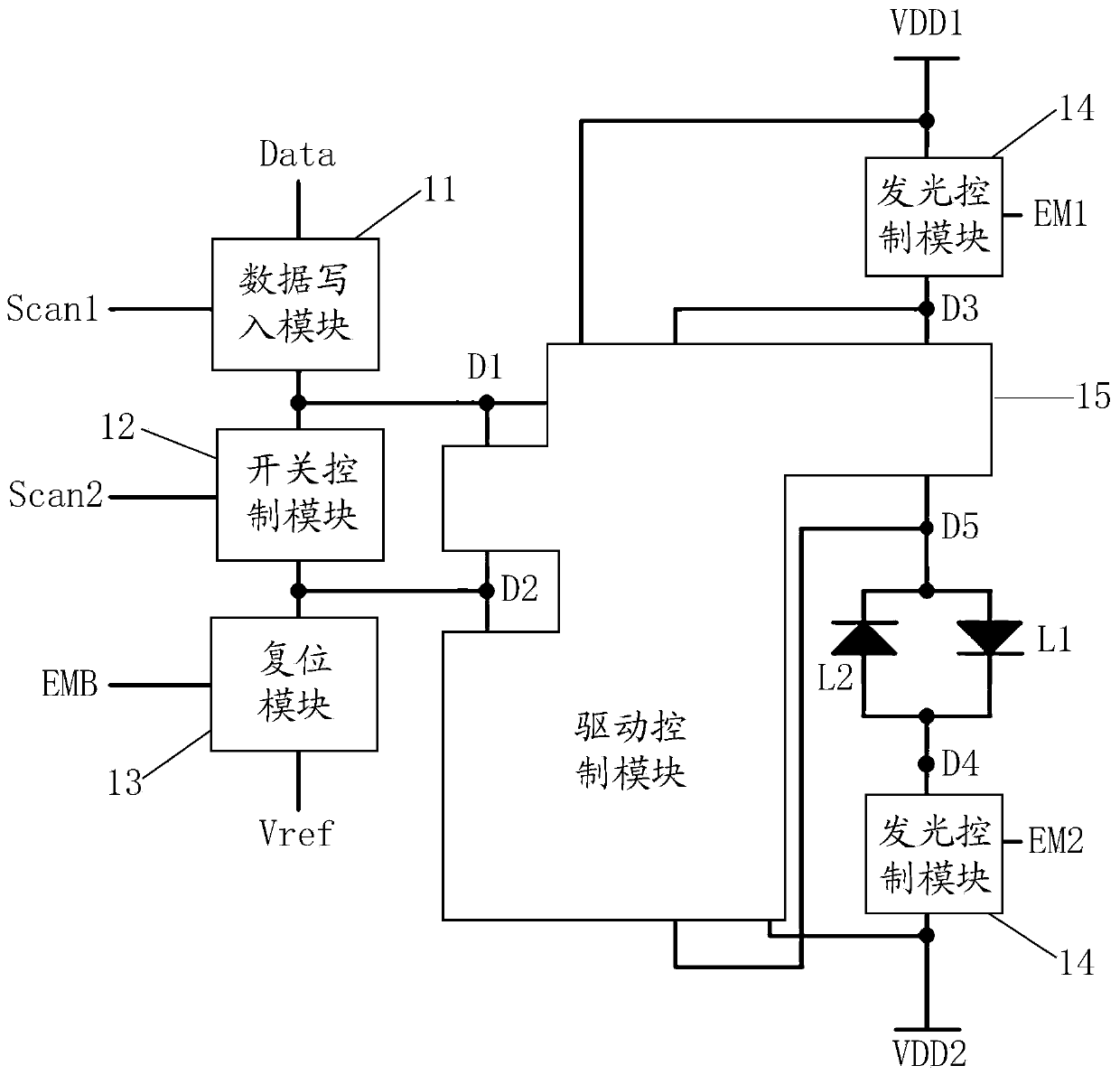

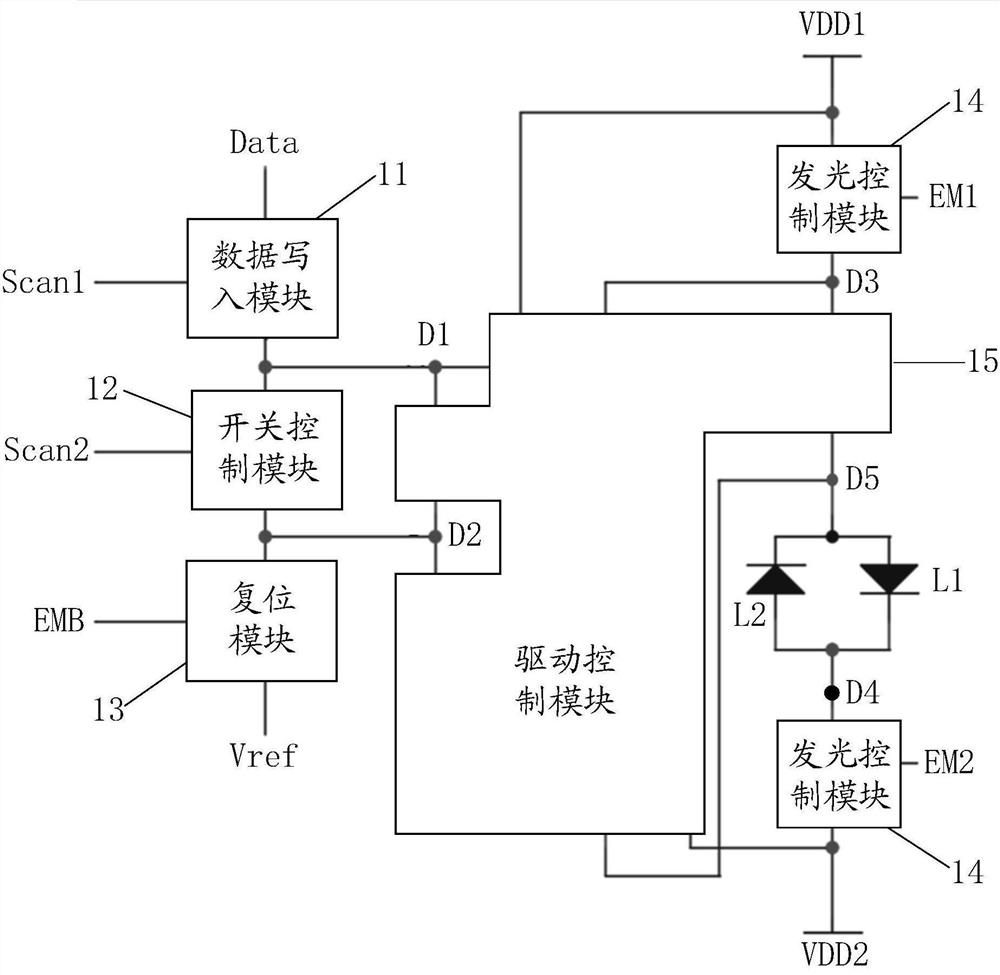

Pixel circuit, driving method thereof, display panel and display device

ActiveCN111261102ASolve afterimage problemImprove display lifeStatic indicating devicesComputer hardwareDisplay device

The invention discloses a pixel circuit, a driving method thereof, a display panel and a display device. The pixel circuit comprises a data writing module, a switch control module, a reset module, a light-emitting control module, a first light-emitting device, a second light-emitting device and a driving control module. The first light-emitting device and the second light-emitting device are arranged, a second electrode of the first light-emitting device is coupled to a first electrode of the second light-emitting device, and a first electrode of the first light-emitting device is coupled to asecond electrode of the second light-emitting device. Through cooperation of the data writing module, the switch control module, the reset module, the light-emitting control module and the driving control module, time-sharing display of the first light-emitting device and the second light-emitting device can be controlled, and long-time static display can be avoided, so that the residual image problem of the OLED display is avoided, the display life of the OLED display is prolonged, and the display performance of the OLED display is improved.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

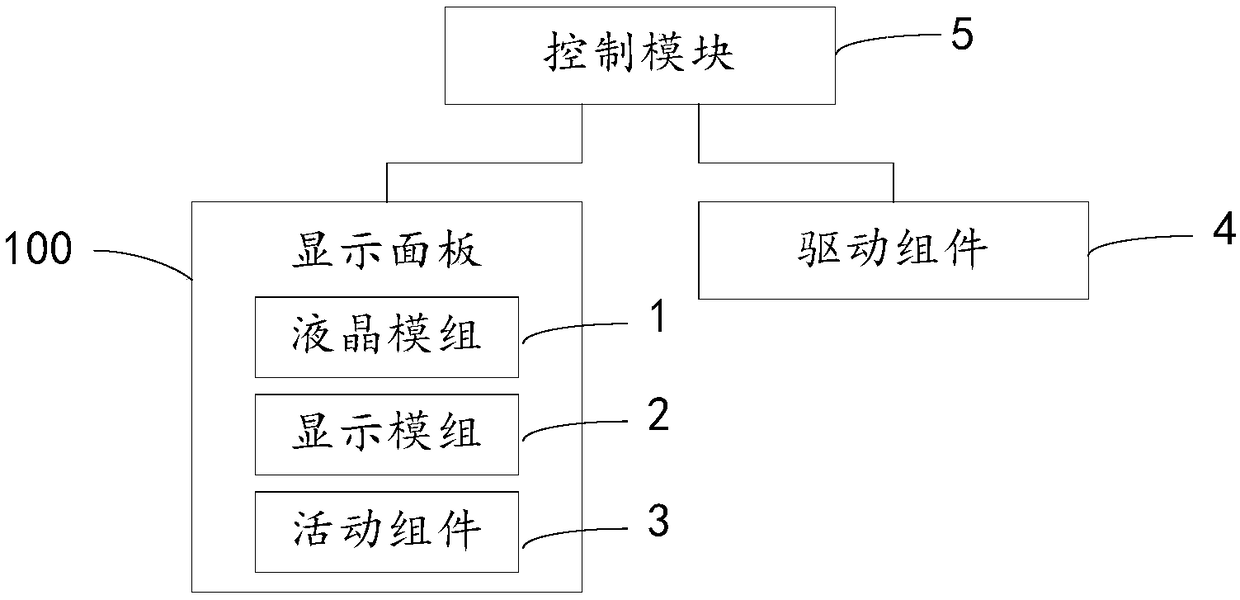

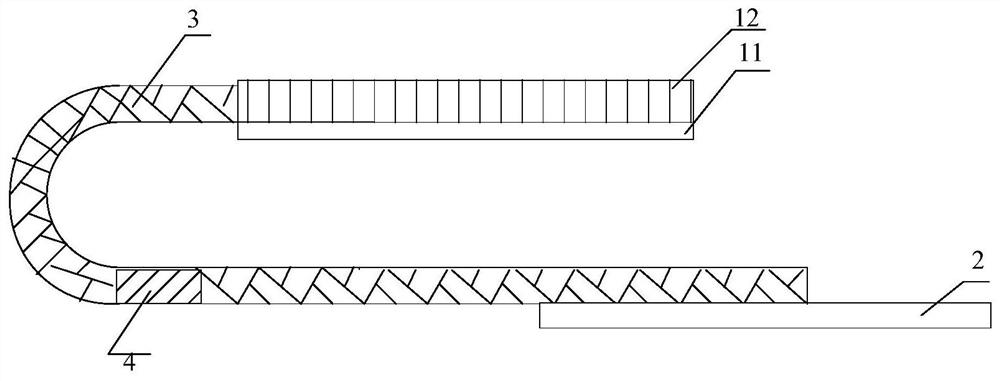

Display panel, display device and control method based on display panel

InactiveCN108761877AAvoid wastingSave spaceElectrical apparatusStatic indicating devicesDisplay deviceComputer science

The invention discloses a display panel, a display device and a control method based on the display panel. The display panel comprises a liquid crystal module and a backlight module arranged on the light incidence side of the liquid crystal module, wherein the liquid crystal module is slidably or reversibly connected with the backlight module through a movable assembly. The display device and theliquid crystal module of the display panel are slidably or reversibly connected with the backlight module through the movable assembly so that the display panel can also be used for illuminationbesides fordisplay. The display panel has the advantages that the utilization rate of the backlight module is high and the display panel is convenient to replace, and meanwhile space and cost are also saved.

Owner:BOE TECH GRP CO LTD +1

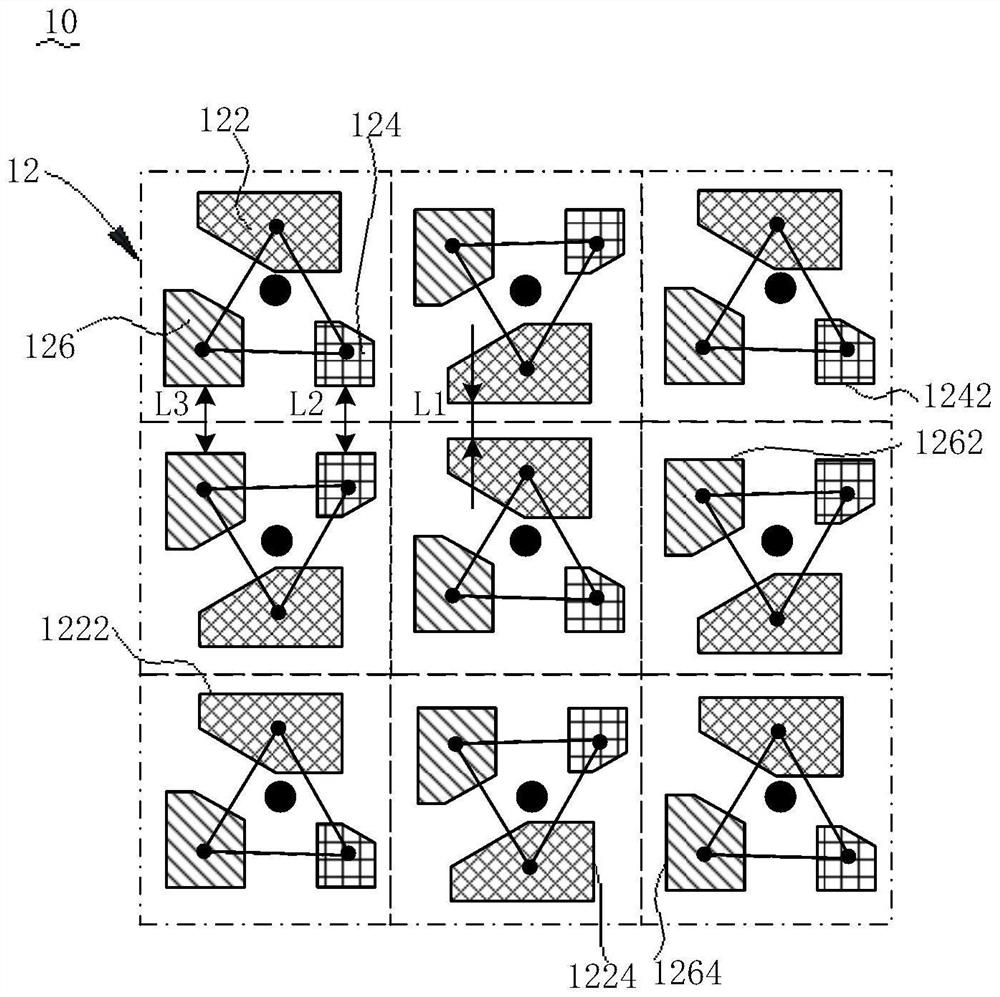

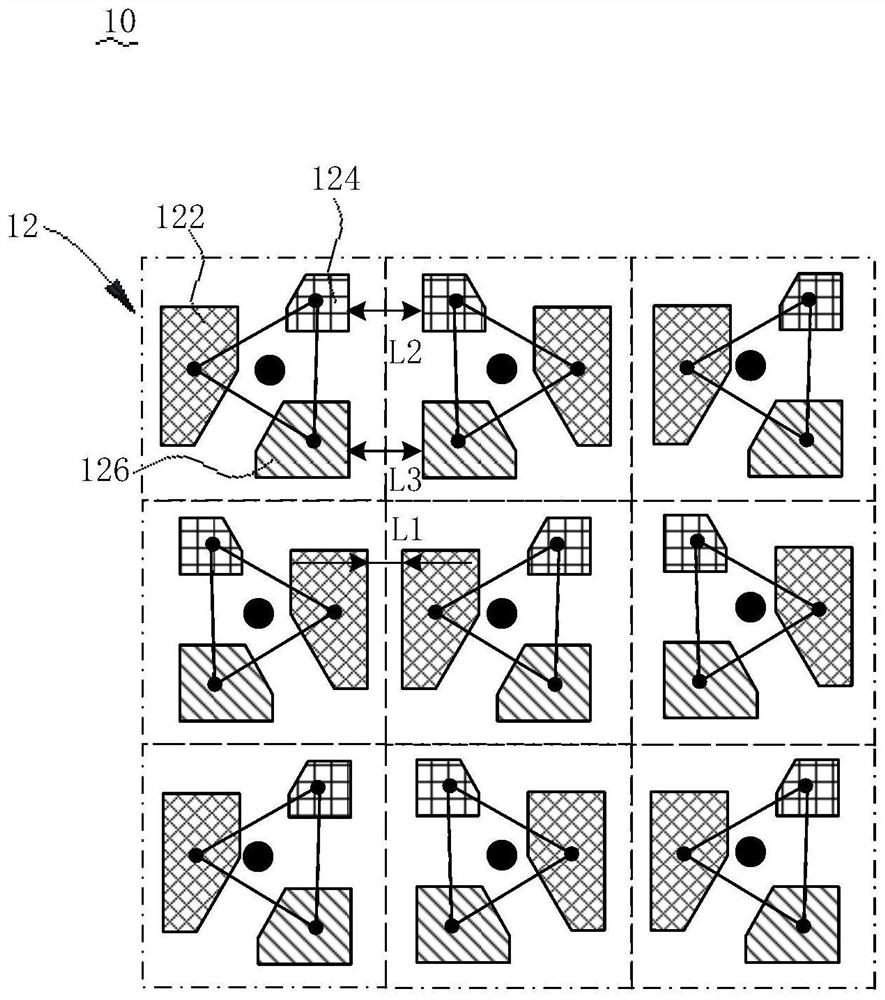

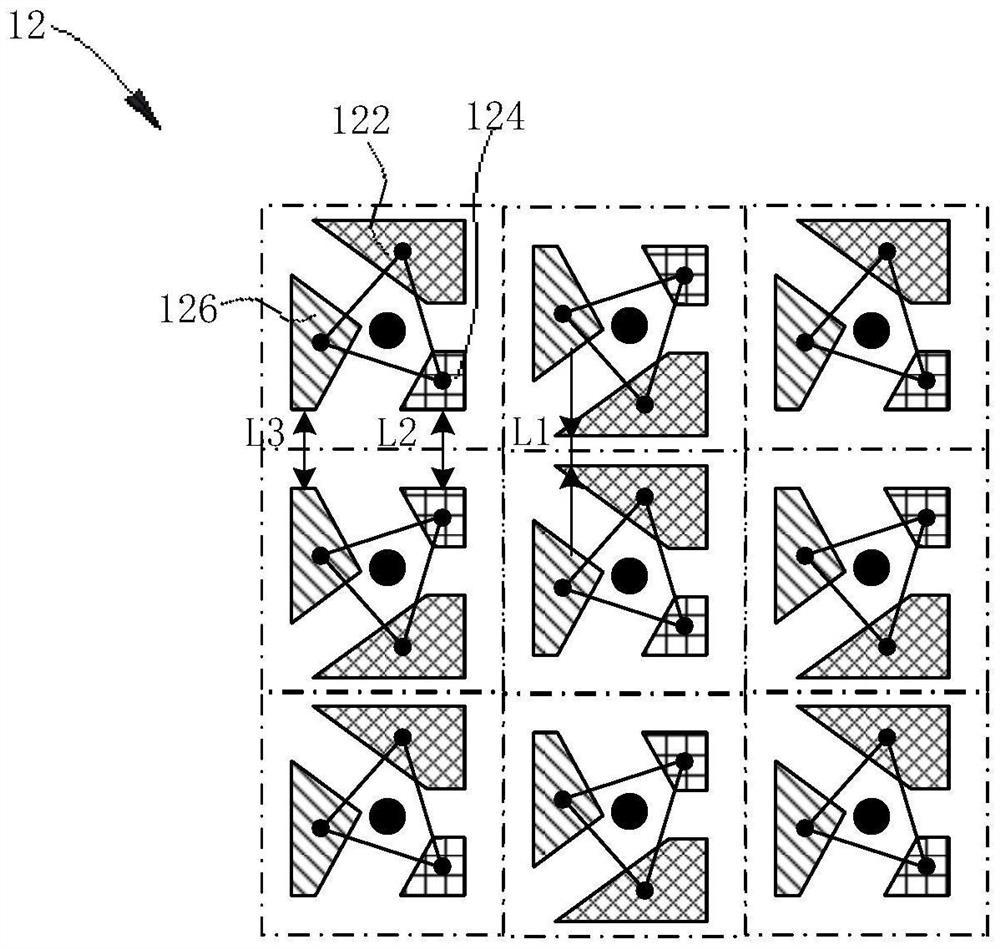

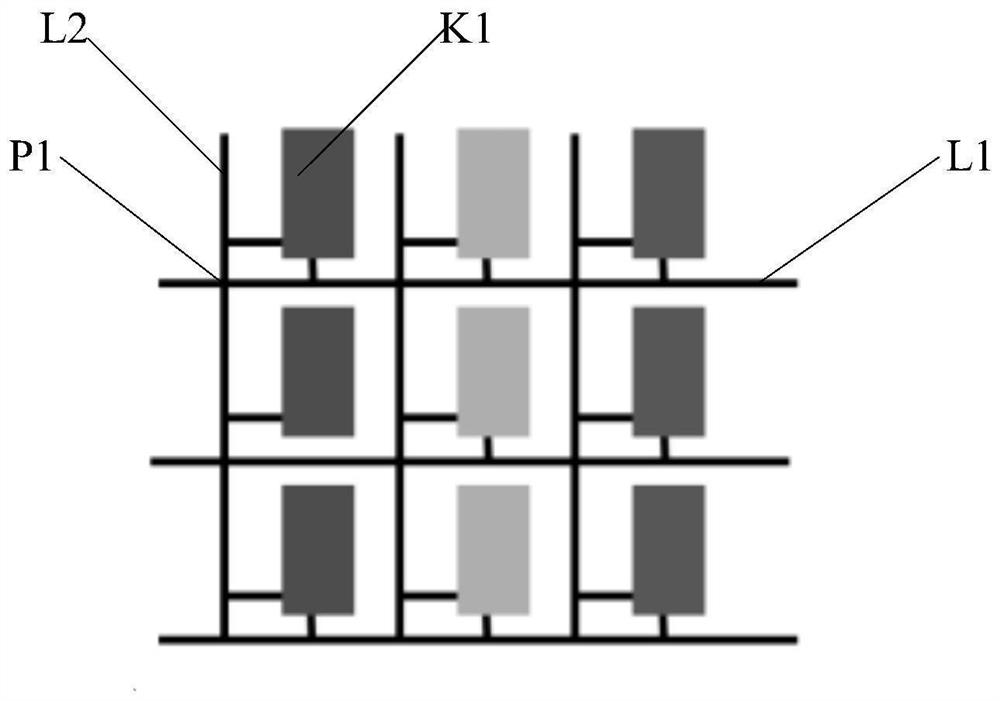

Display panel, mask assembly and display equipment

PendingCN114361232AHigh-resolutionImprove display lifeSolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareComputer graphics (images)

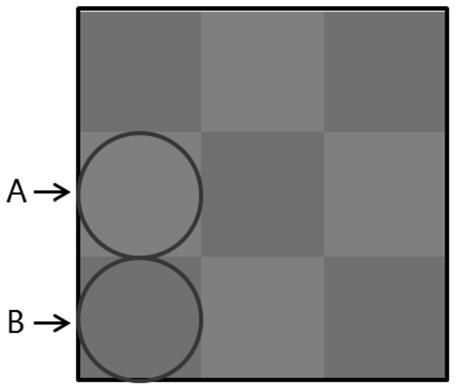

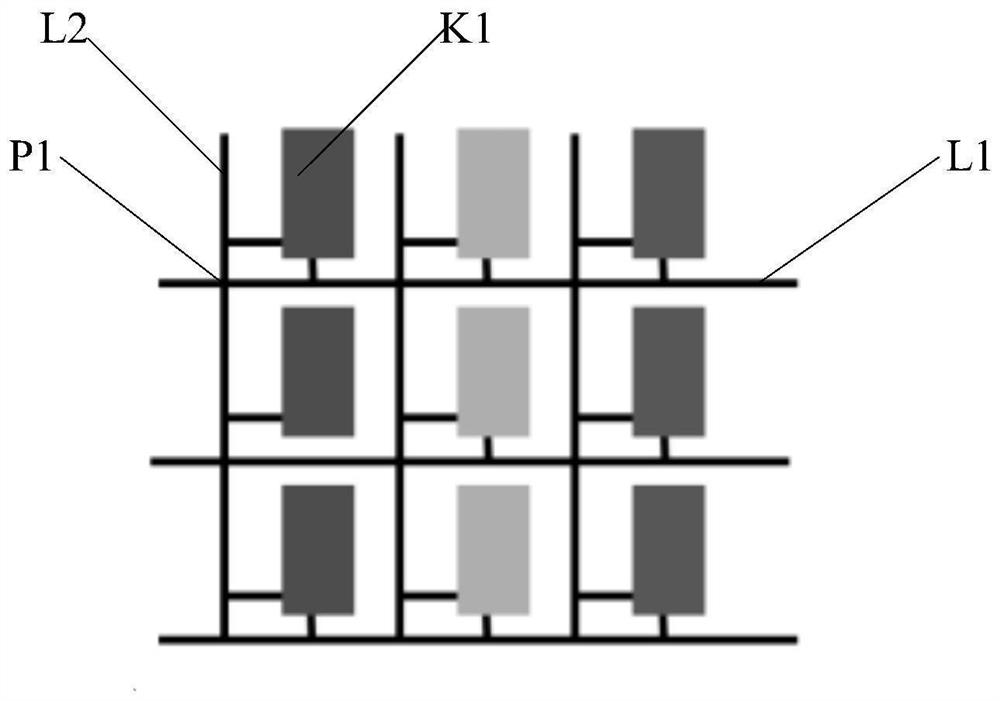

The invention provides a display panel, a mask assembly and a display device, the display panel comprises pixel units, each pixel unit comprises a first sub-pixel, a second sub-pixel and a third sub-pixel, the center connecting lines of the three sub-pixels are arranged in a triangle shape, the second sub-pixel and the third sub-pixel are arranged in the first direction, and the second sub-pixel and the third sub-pixel are arranged in the second direction. The first sub-pixels of the two adjacent pixel units in the second direction are arranged adjacently, or the second sub-pixels of the two pixel units are arranged adjacently and the third sub-pixels are arranged adjacently, and the distances between the three sub-pixels in the pixel units and the corresponding adjacent sub-pixels in the second direction are partially the same and partially different. By arranging the pixel units and the sub-pixels in the pixel units, high-resolution display is achieved, aperture ratio proportion adjustment is facilitated, and the maximum service life of the device is achieved.

Owner:BOE TECH GRP CO LTD

Reversal displaying device

InactiveCN107644597APrevent display glitchesImprove display lifeIdentification meansAutomatic controlComputer module

Owner:东莞市闻誉实业有限公司

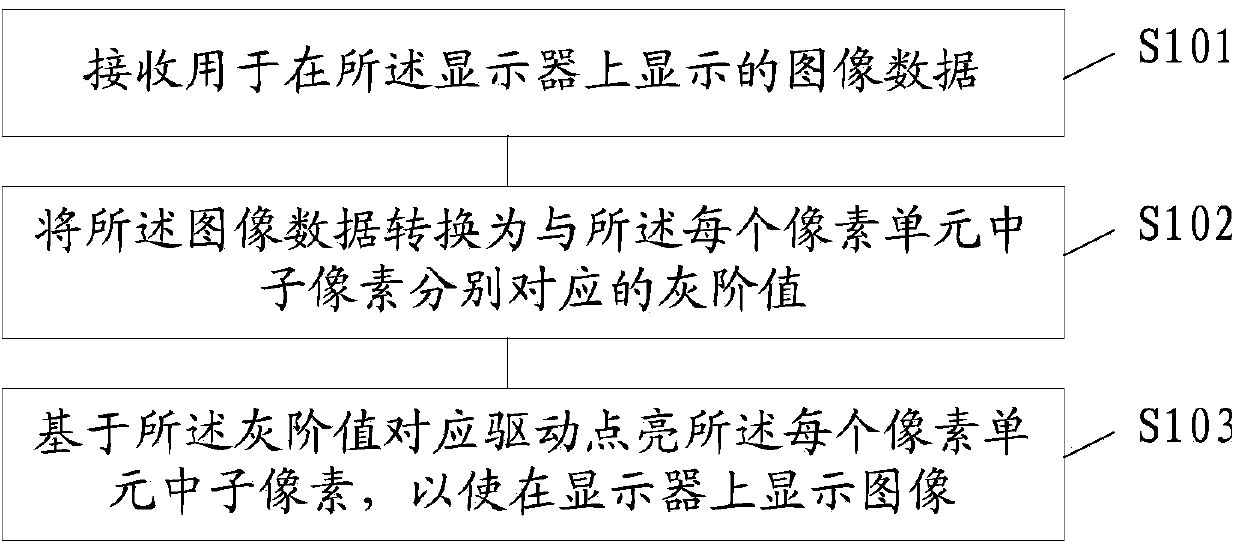

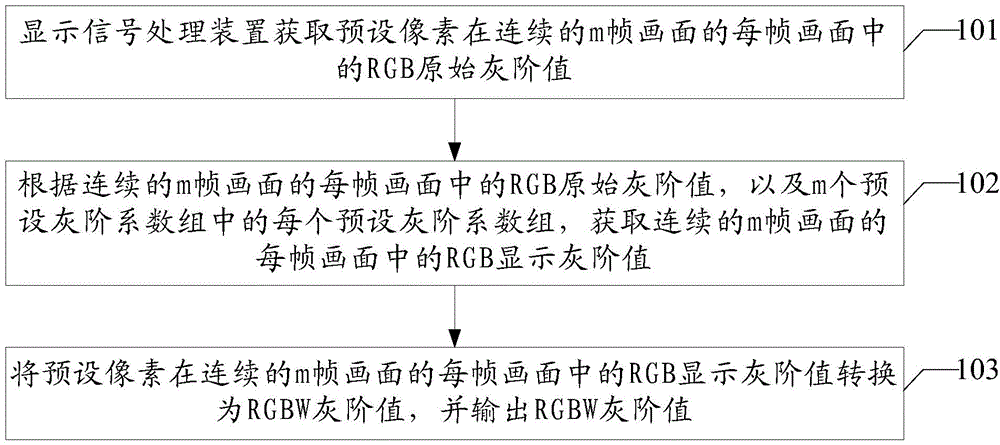

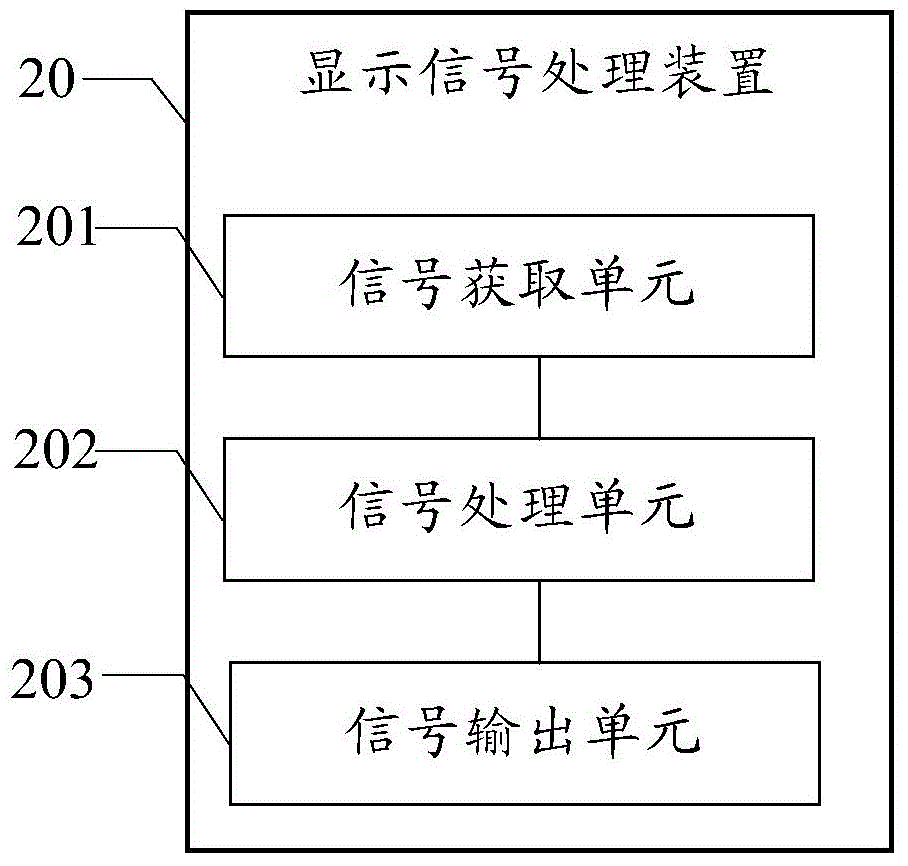

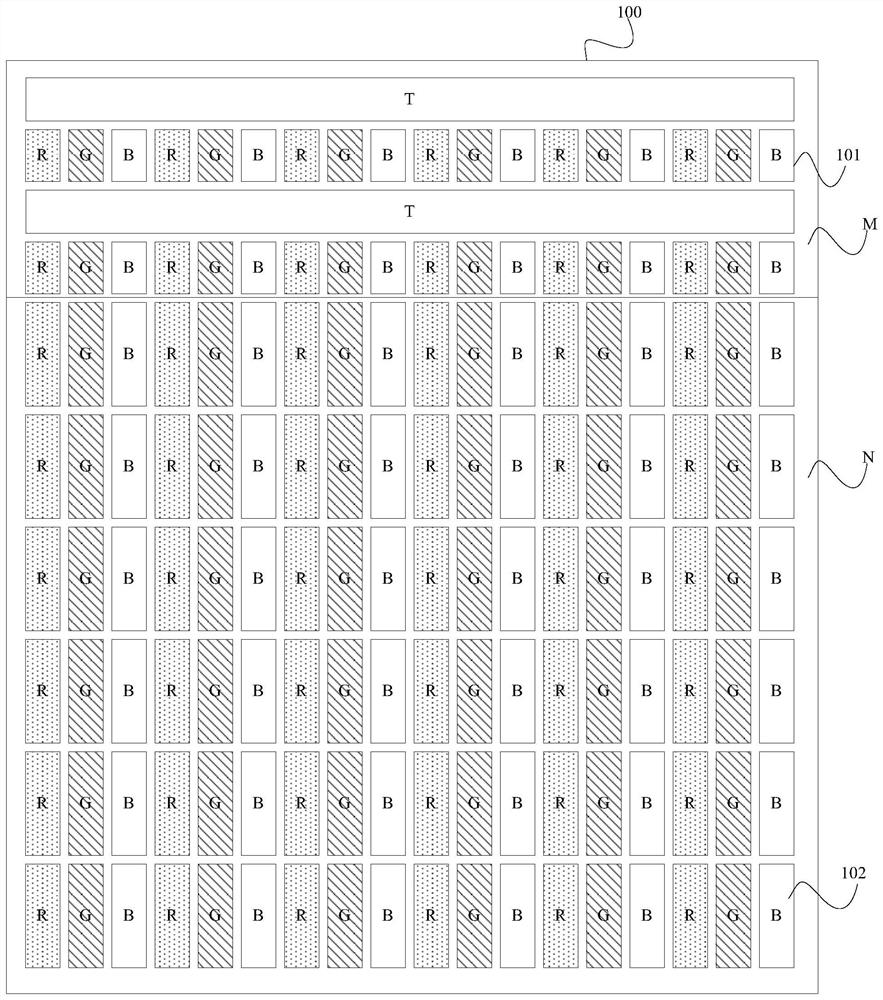

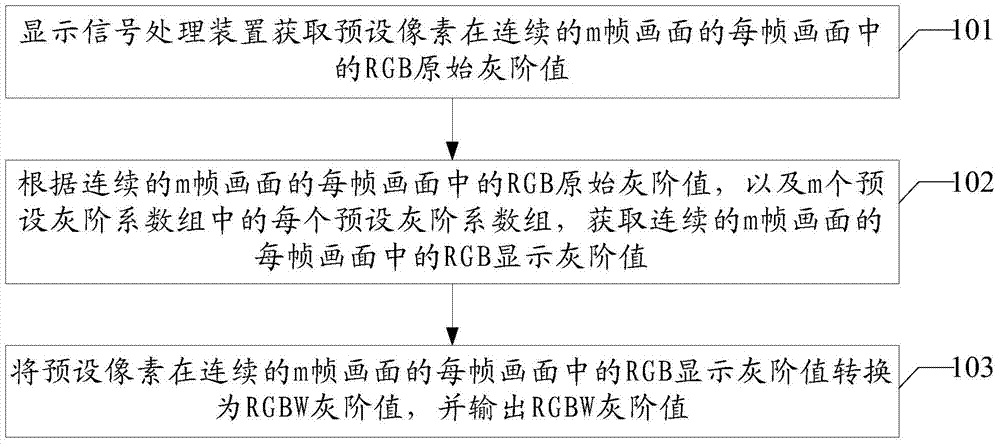

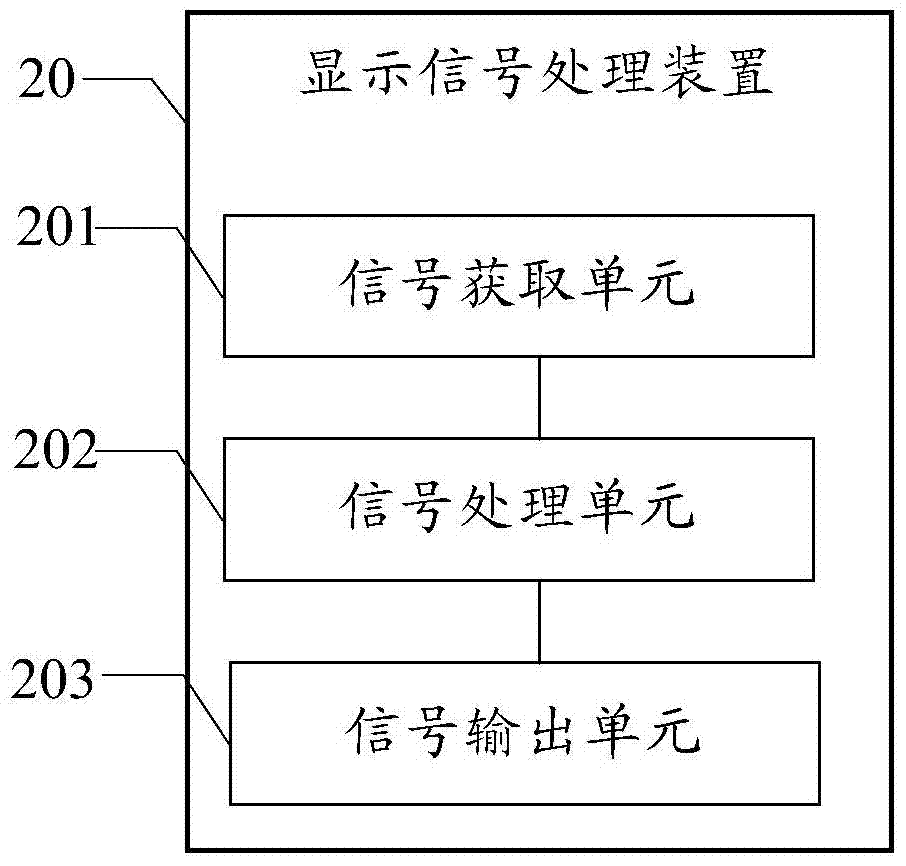

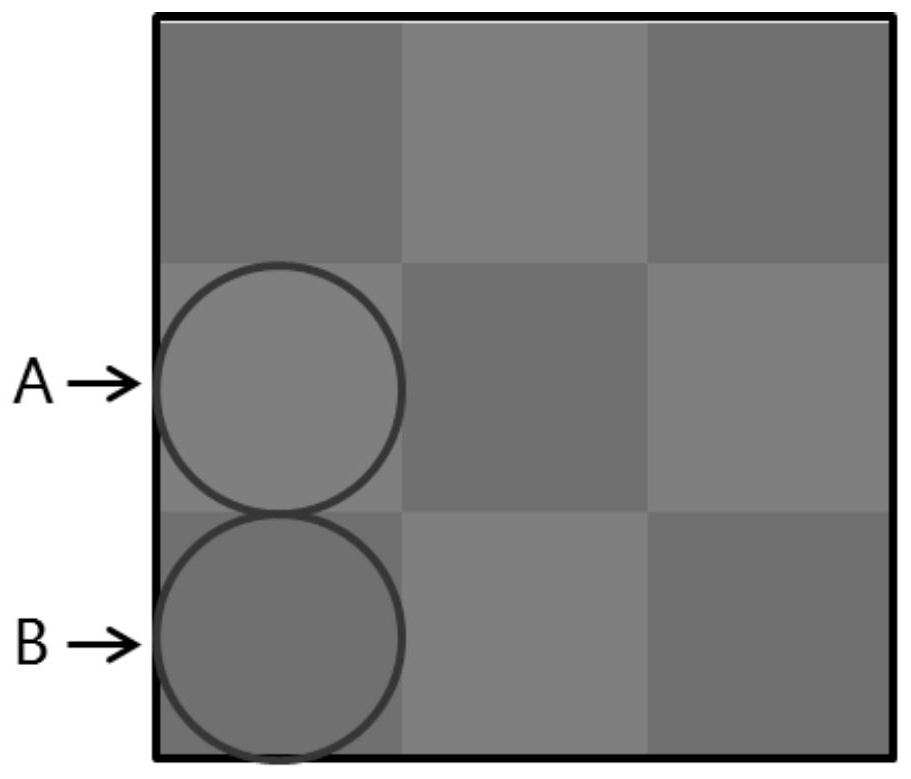

Display signal processing method and device and self-luminous monitor

ActiveCN104575391AReduce workloadImprove display lifeStatic indicating devicesArray data structureSignal processing

An embodiment of the invention provides a display signal processing method and device and a self-luminous monitor and relates to the field of display. By the display signal processing method and device, display life of pixels in the self-luminous monitor can be prolonged, and display life of the self-luminous monitor is integrally prolonged. The display signal processing method includes steps of acquiring RGB (Red Green Blue) gray-scale values (X, Y, Z) of preset pixels, acquiring m groups of RGB display gray-scale values (Xi, Yi, Zi) according to the RGB gray-scale values (X, Y, Z) and preset m gray-scale coefficient groups (Ui, Vi, Wi), and outputting m groups of scanning gray-scale values for continuously scanning the preset pixels within a display period m times according to m groups of RGB display gray-scale value (Xi, Yi, Zi). The display signal processing method is used for processing display signals of the monitor.

Owner:HISENSE VISUAL TECH CO LTD

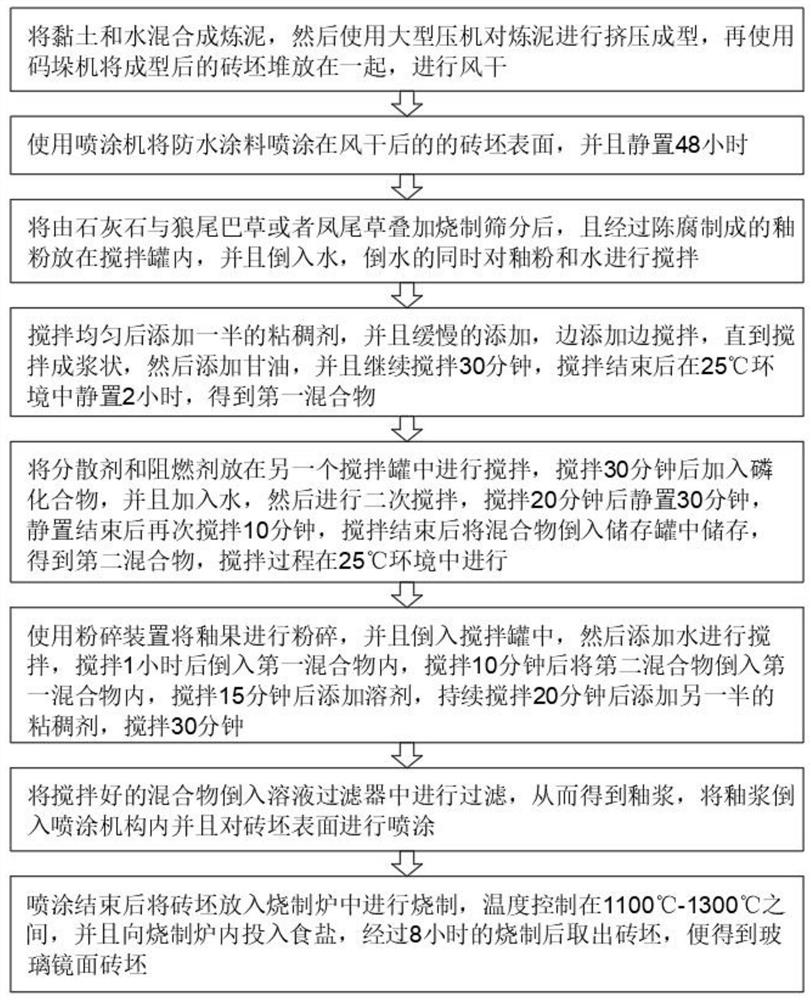

Glass mirror surface green brick with uniform surface glaze slip and manufacturing method thereof

The invention discloses a glass mirror surface green brick with uniform surface glaze slip and a manufacturing method thereof, relates to the technical field of ceramic glaze slip, and aims to solve the problem that the existing ceramic glaze slip is easy to flow after being sprayed and thus the glaze slip is inconvenient to uniformly spray on the green brick. The glass mirror surface green brick comprises a green brick body. The glass mirror surface green brick is characterized in that the outer wall of the green brick body is provided with a waterproof coating, the waterproof coating is connected with the green brick main body in a spraying manner, the outer wall of the waterproof coating is provided with glaze slip, the glaze slip is connected with the waterproof coating in a spraying manner, and the glaze slip is prepared from the following raw materials in percentage by weight: 35-55% of glaze powder; 30-60% of water; 10-15% of a dispersant; 5-10% of a flame retardant; 1-5% of a phosphorus compound; 5-10% of a thickener; 5-15% of salt; 30-50% of a solvent; 5-10% of glycerin; and 40-70% of glaze stone.

Owner:安徽昆仑新材料科技股份有限公司

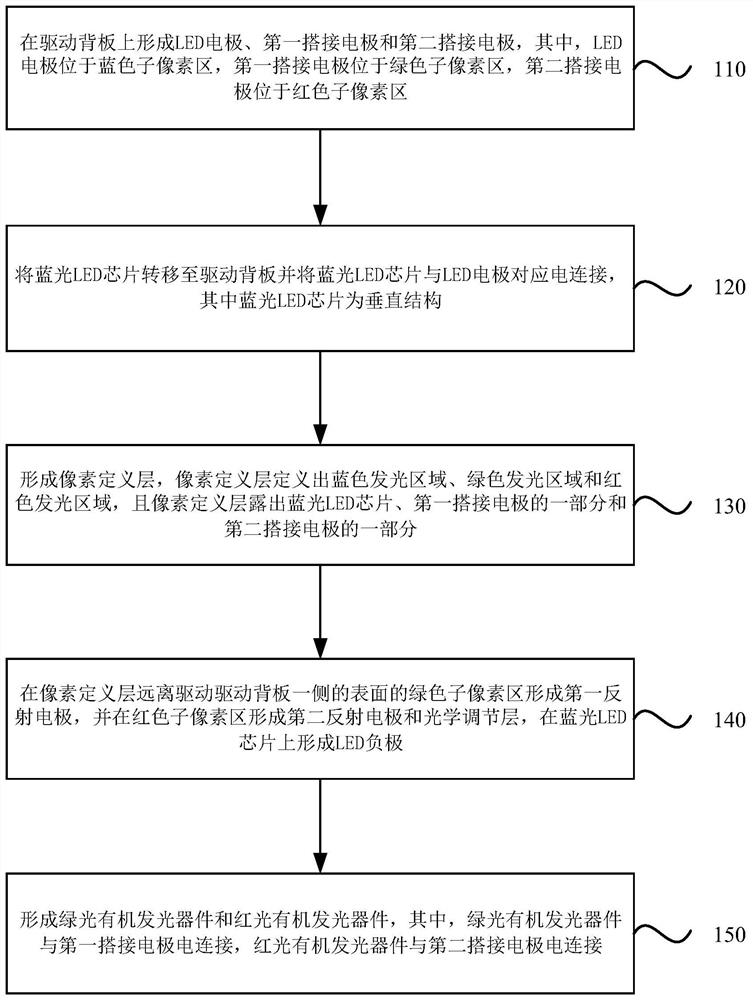

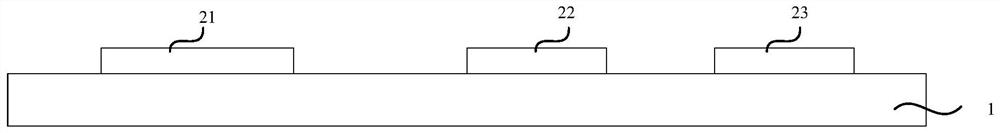

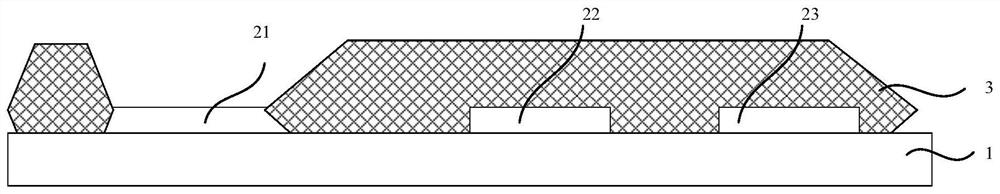

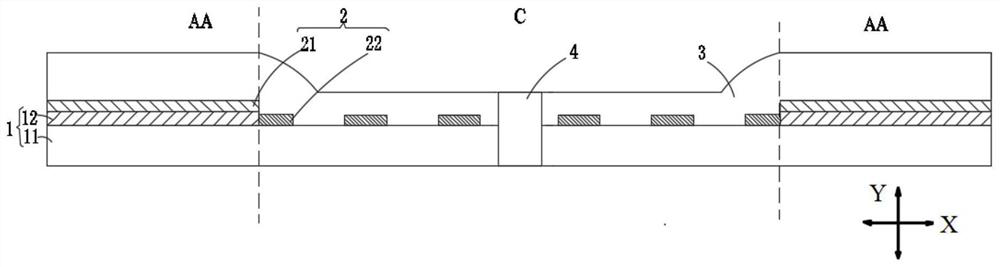

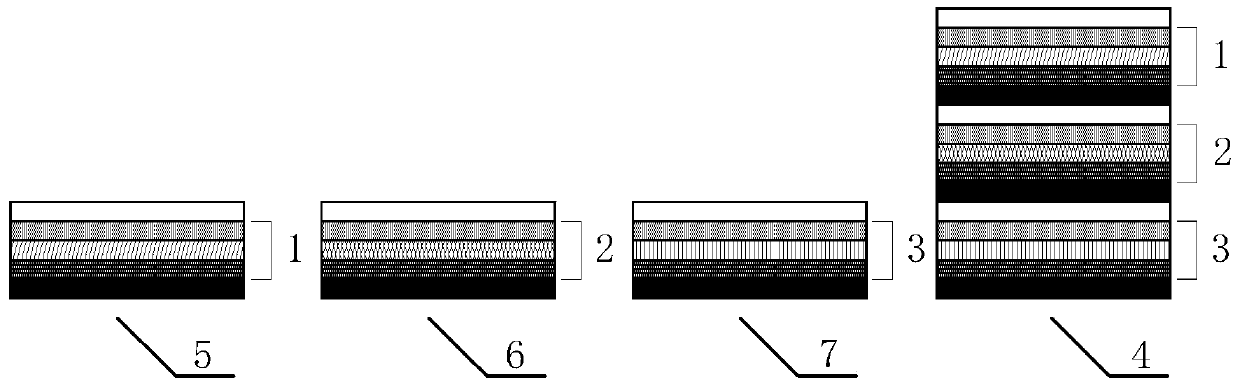

Preparation method of OLED hybrid display panel, and display panel

ActiveCN111697047ASmall sizeImprove cooling effectSolid-state devicesSemiconductor devicesOrganic light emitting deviceEngineering

The invention discloses a preparation method of an OLED hybrid display panel, and the display panel. The preparation method of the display panel comprises the steps: forming an LED electrode, a firstlap joint electrode and a second lap joint electrode on a driving backboard; transferring a blue-light LED chip to the driving backboard and correspondingly and electrically connecting the blue-lightLED chip with a LED electrode, wherein the blue-light LED chip is of a vertical structure; forming a pixel definition layer to expose the blue light LED chip, a part of the first lap joint electrode and a part of the second lap joint electrode; forming a first reflection electrode in a green sub-pixel region on the surface of one side, far away from the driving backboard, of the pixel definition layer, forming a second reflection electrode and an optical adjustment layer in a red sub-pixel area, and forming an LED negative electrode on a blue light LED chip, wherein the LED negative electrodeand an optical adjustment layer are located on the same layer, and the LED electrode comprises an LED positive electrode; and forming a green light organic light emitting device and a red light organic light emitting device. According to the technical scheme provided by the embodiment of the invention, the heat dissipation performance of the display panel is improved.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

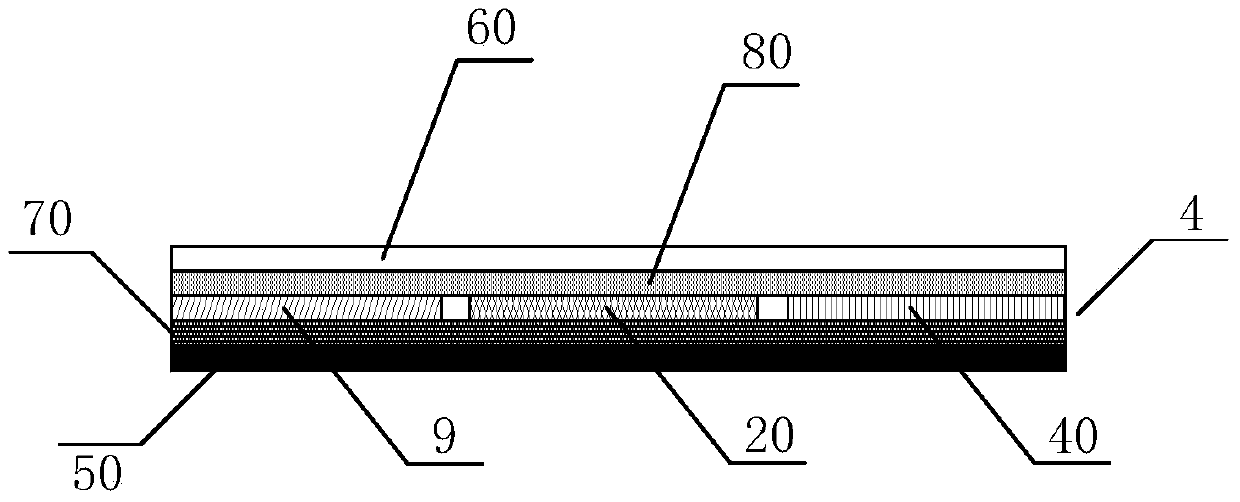

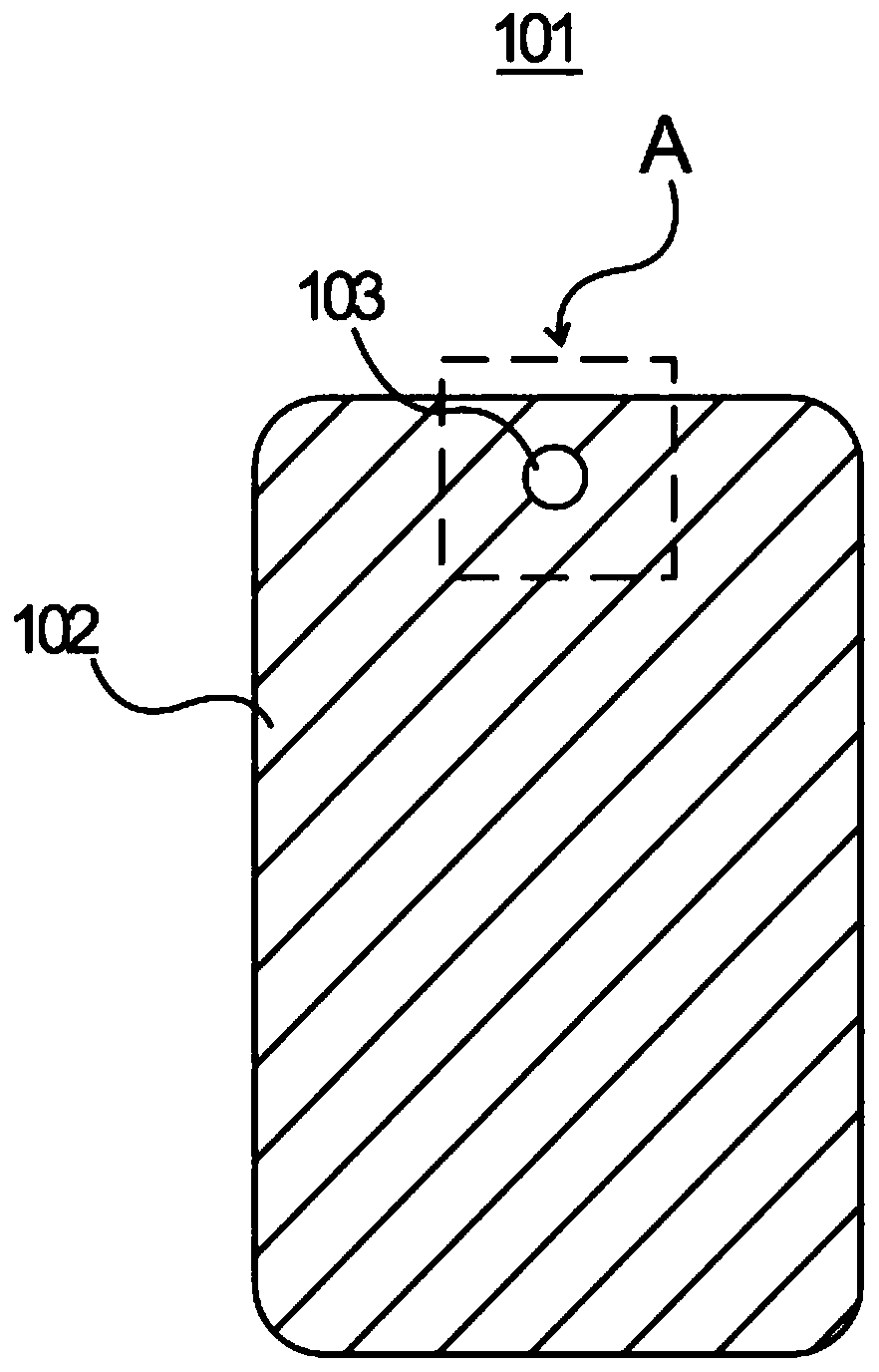

Display device, display panel and manufacturing method of display panel

ActiveCN113066932AImprove display lifeAvoid corrosion damageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display device, a display panel and a manufacturing method of the display panel. The display panel is provided with a hole, a blocking area surrounding the hole and a display area surrounding the blocking area. The display panel comprises an array substrate; a light-emitting material layer which is arranged on the array substrate in a stacked mode, wherein the light-emitting material layer is provided with light-emitting parts and blocking parts, the light-emitting parts are continuously distributed in the display area, the blocking parts are located in the blocking areas and distributed between the holes and the light-emitting parts at intervals, and a gap zone for exposing the array substrate is formed between every two adjacent blocking parts; and a packaging film layer which covers the light-emitting part, the barrier parts and the surface of the array substrate exposed through the gap band. he blocking parts located in the blocking area are discontinuous and are interrupted by the gap zone, the packaging film layer which is not prone to corrosion covers the gap zone, external water vapor is completely blocked in the blocking area, corrosion damage to the light-emitting portion by the external water vapor is avoided, and the display service life of the display panel is prolonged.

Owner:HEFEI VISIONOX TECH CO LTD

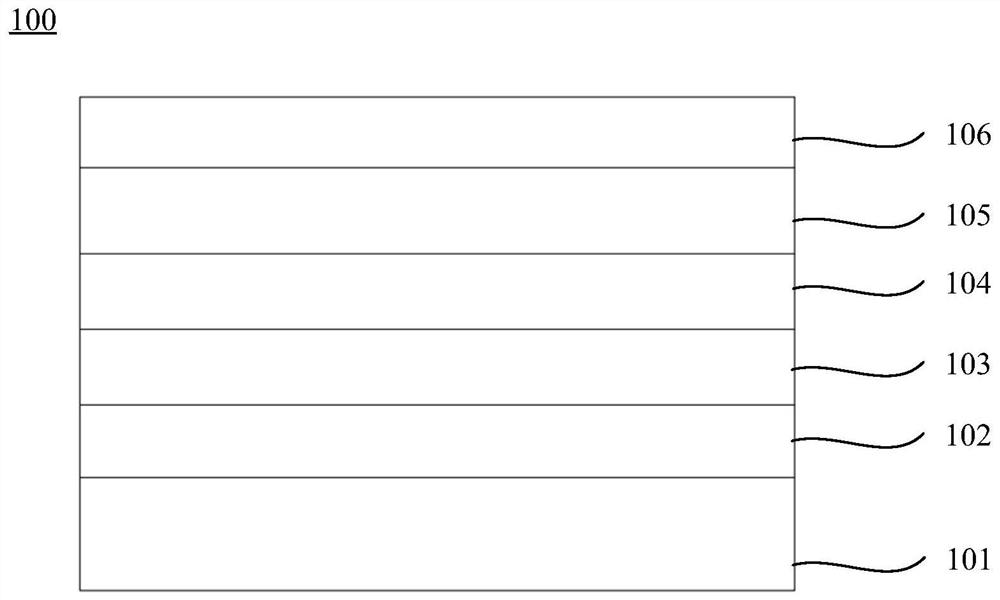

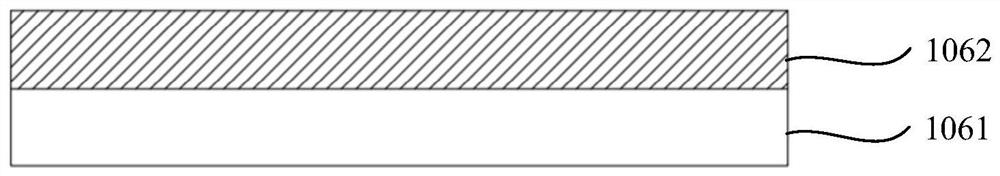

Display panel and display device

InactiveCN113178533AImprove display lifeEnhance eye protection functionSolid-state devicesSemiconductor/solid-state device manufacturingProtecting eyeUltraviolet lights

The invention provides a display panel and a display device. The display panel comprises a substrate, a light-emitting functional layer located on the substrate, a coupling light-emitting layer located on the light-emitting functional layer, and a Bragg reflection layer located on the coupling light-emitting layer. According to the invention, the Bragg reflection layer is arranged on the coupling light emitting layer, and the Bragg reflection layer is periodically provided with the high-low refractive index layer doped with the ultraviolet light absorber, so that the damage of external ultraviolet light to the material of the light emitting functional layer is reduced, the display life of the display panel is prolonged, the eye protection function of the display panel is enhanced, and the market competitiveness of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

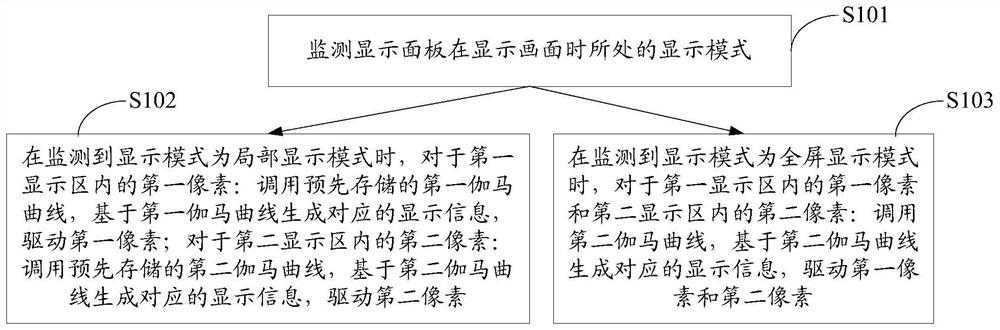

A driving method of a display panel, a driving device thereof, and a display device

ActiveCN110634434BReduce brightnessImprove display lifeCathode-ray tube indicatorsComputer hardwareComputer graphics (images)

The invention discloses a driving method of a display panel, a driving device thereof and a display device. In a partial display mode, different gamma curves are called for different display areas to drive different areas of the same screen. Specifically, the first display area corresponding to the setting of the under-screen sensor can call the first gamma curve with lower brightness, that is, the first display area is driven by the first gamma curve with lower brightness, which corresponds to the first gamma curve of normal display. The second display area can call the second gamma curve with higher brightness, that is, the second display area is driven by the second gamma curve with higher brightness, so that the first display area has a lower brightness than the second display area, which can Avoid and prevent the life span reduction caused by the high brightness display of the first display area for a long time.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Display panel, display device and display panel production method

ActiveCN113161405AImprove display lifeReduce gas contentSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides a display panel, a display device and a display panel production method. The display panel comprises a display area and a non-display area surrounding the display area, and the non-display area comprises a bending area; a substrate and a driving device layer arranged on the substrate are included, wherein the driving device layer comprises a pixel driving array located in the display area and a plurality of wires located in the bending area; and a composite adhesive film is included and located in the bending area and arranged on the side, away from the substrate, of the driving device layer, and fiber materials are doped in the composite adhesive film. According to the display panel provided by the embodiment of the invention, the electronic device in the bending area is protected through the composite adhesive film provided with the functional layer so that the display life of the display panel is prolonged.

Owner:YUNGU GUAN TECH CO LTD

Turnover box cover locking structure

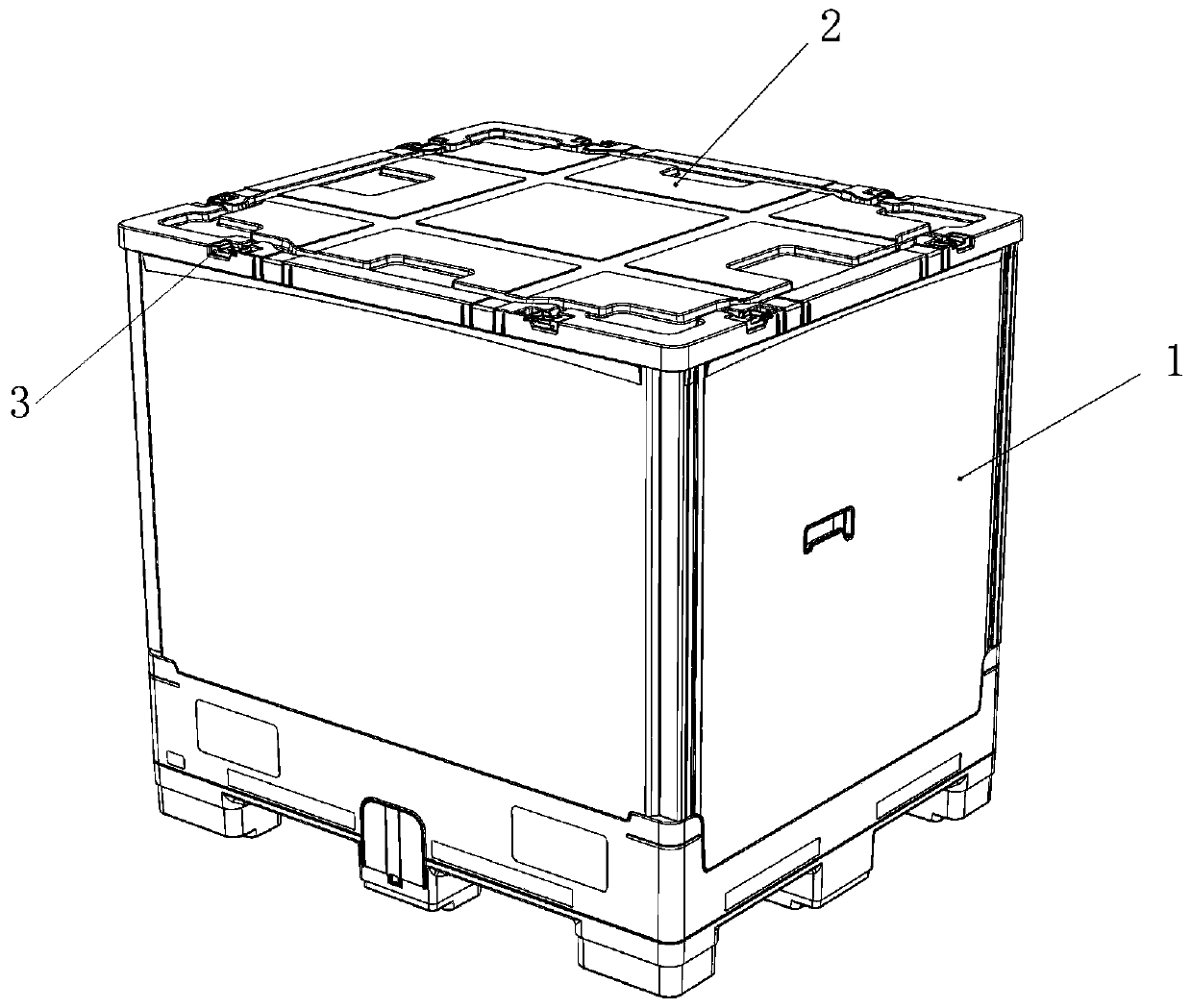

PendingCN110902136AImprove securityAchieve positioningLocking devicesStructural engineeringMechanical engineering

Owner:SHANGHAI PALLET PLASTIC

Display signal processing method and device, self-luminous display

ActiveCN104575391BReduce workloadImprove display lifeStatic indicating devicesArray data structureGray level

Embodiments of the present invention provide a display signal processing method and device, and a self-luminous display, which relate to the display field and can improve the display life of pixels in the self-luminous display, thereby improving the display life of the self-luminous display as a whole. The specific scheme is: obtain the RGB grayscale value (X, Y, Z) of the preset pixel, according to the RGB grayscale value (X, Y, Z), and the preset m grayscale coefficient groups (Ui, Vi , Wi), obtain m groups of RGB display grayscale values (Xi, Yi, Zi), according to the m groups of RGB display grayscale values (Xi, Yi, Zi), output m groups of scanning grayscale values, for all The preset pixels are scanned m times continuously in one display period. The invention is used for the display signal processing of the display.

Owner:HISENSE VISUAL TECH CO LTD

Display substrate, manufacturing method thereof, and display device

ActiveCN108269835BGood strain elasticityImprove bending resistanceSolid-state devicesSemiconductor devicesDisplay deviceThin membrane

The invention provides a display substrate, a manufacturing method thereof, and a display device. The display substrate includes a display area arranged on the substrate, and at least one PMOLED is included in the bending area of the display area. Since the PMOLED is not driven by a thin film transistor, it effectively avoids the impact of the electrical change caused by the bending of the thin film transistor. The influence of display performance, further, an organic insulating layer is included between the substrate and the first OLED unit, and the organic insulating layer includes an organic material. Since the organic material has good strain elasticity compared to the inorganic material, The bending resistance of the bending area can be improved. The display lifespan of the display area can be effectively improved by using the manufacturing method of the display substrate provided by the present invention. The display device provided by the present invention comprising the above display substrate includes at least one PMOLED in the bending area of the display area, which can avoid display performance changes caused by bending of thin film transistors.

Owner:YUNGU GUAN TECH CO LTD

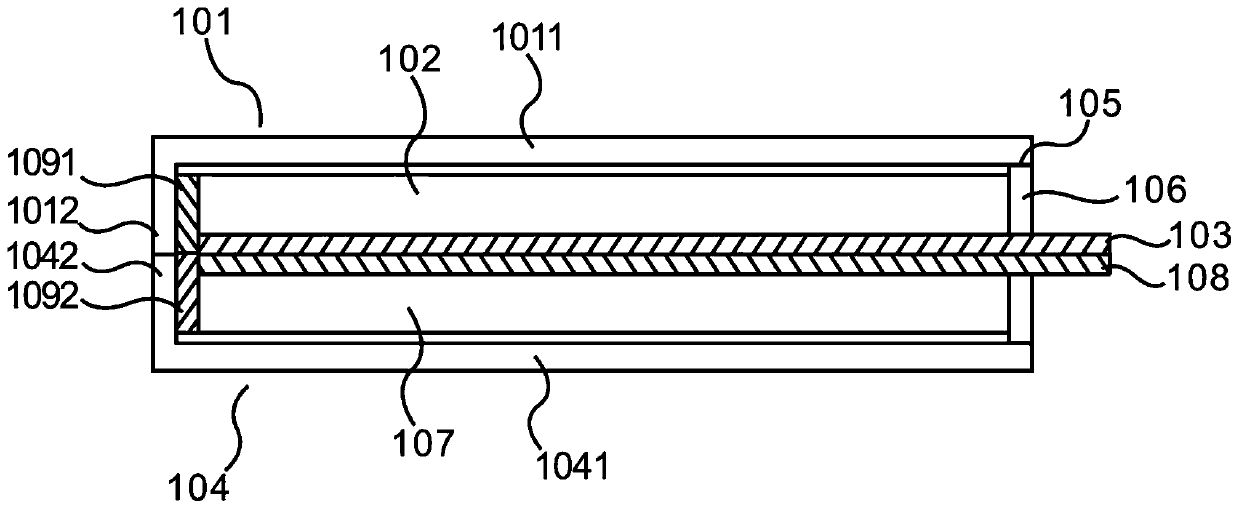

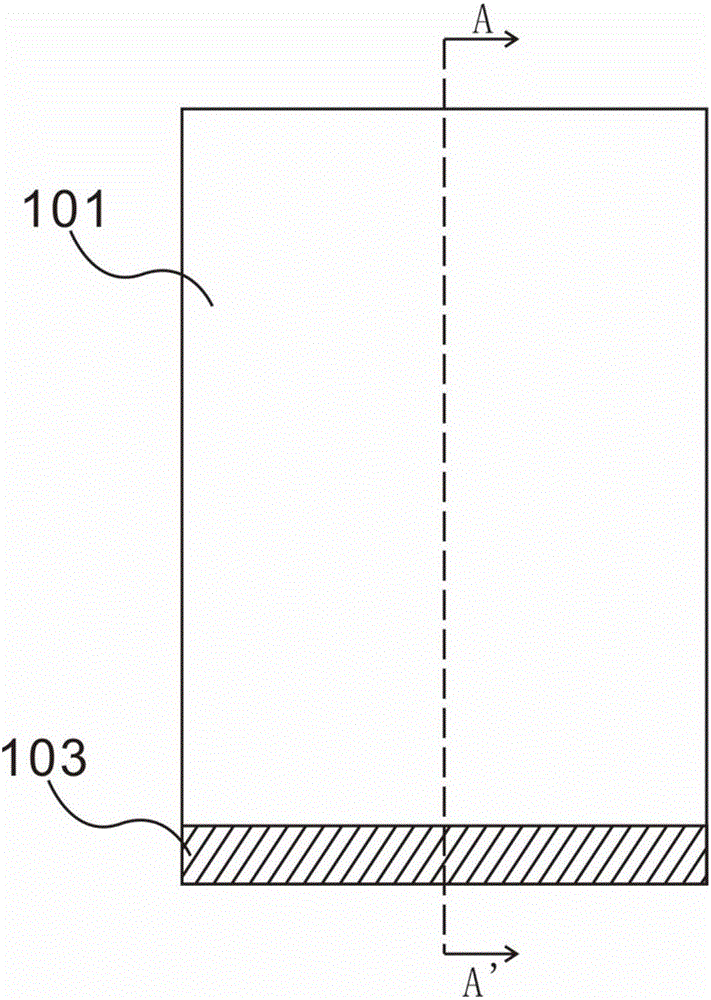

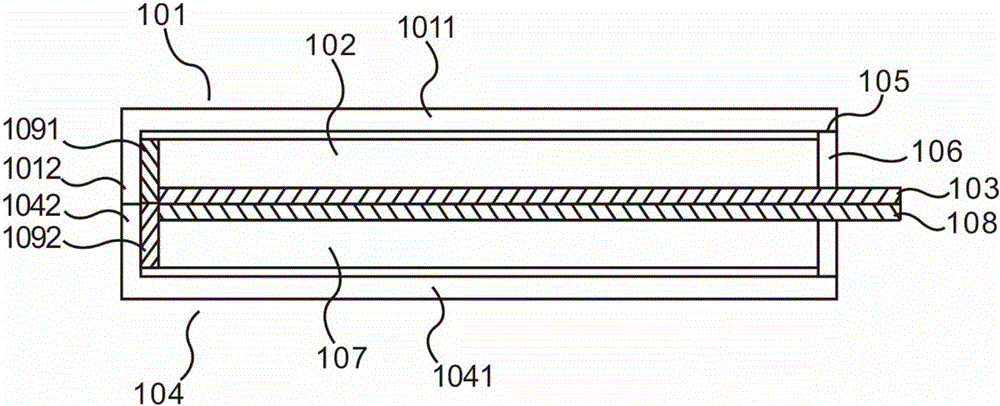

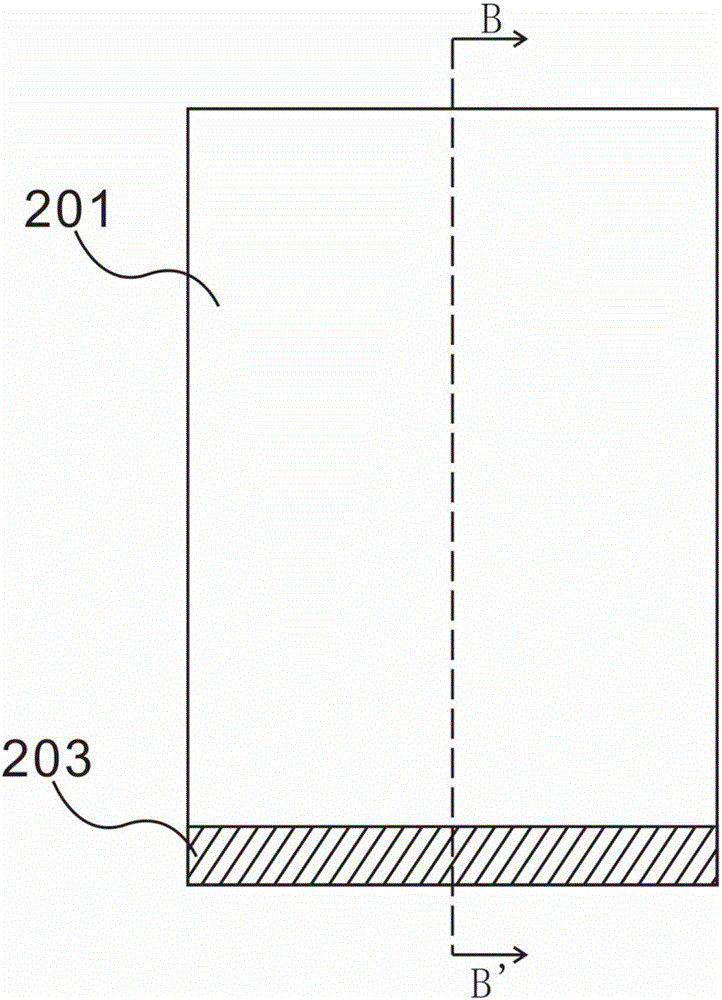

Double-sided oled display and packaging method thereof

ActiveCN106783914BProtect from high temperature damageImprove display lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a double-sided OLED packaging structure, which includes an upper plate and a lower plate. A bending structure is arranged on the edge of the upper plate and the lower plate, and an encapsulating glue is arranged inside the bending structure, so that the first base, The side parts of the second base are correspondingly connected to the bending structure through the encapsulation glue; the beneficial effect is: in the double-sided OLED encapsulation structure of the present invention, the encapsulation glue is arranged on the side of the encapsulation cover, away from the light-emitting surface, thereby protecting the organic light emitting Layers are protected from high temperature damage to extend display life; the sides of the package lid can be thinned to help reduce the bezel width of double-sided displays.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

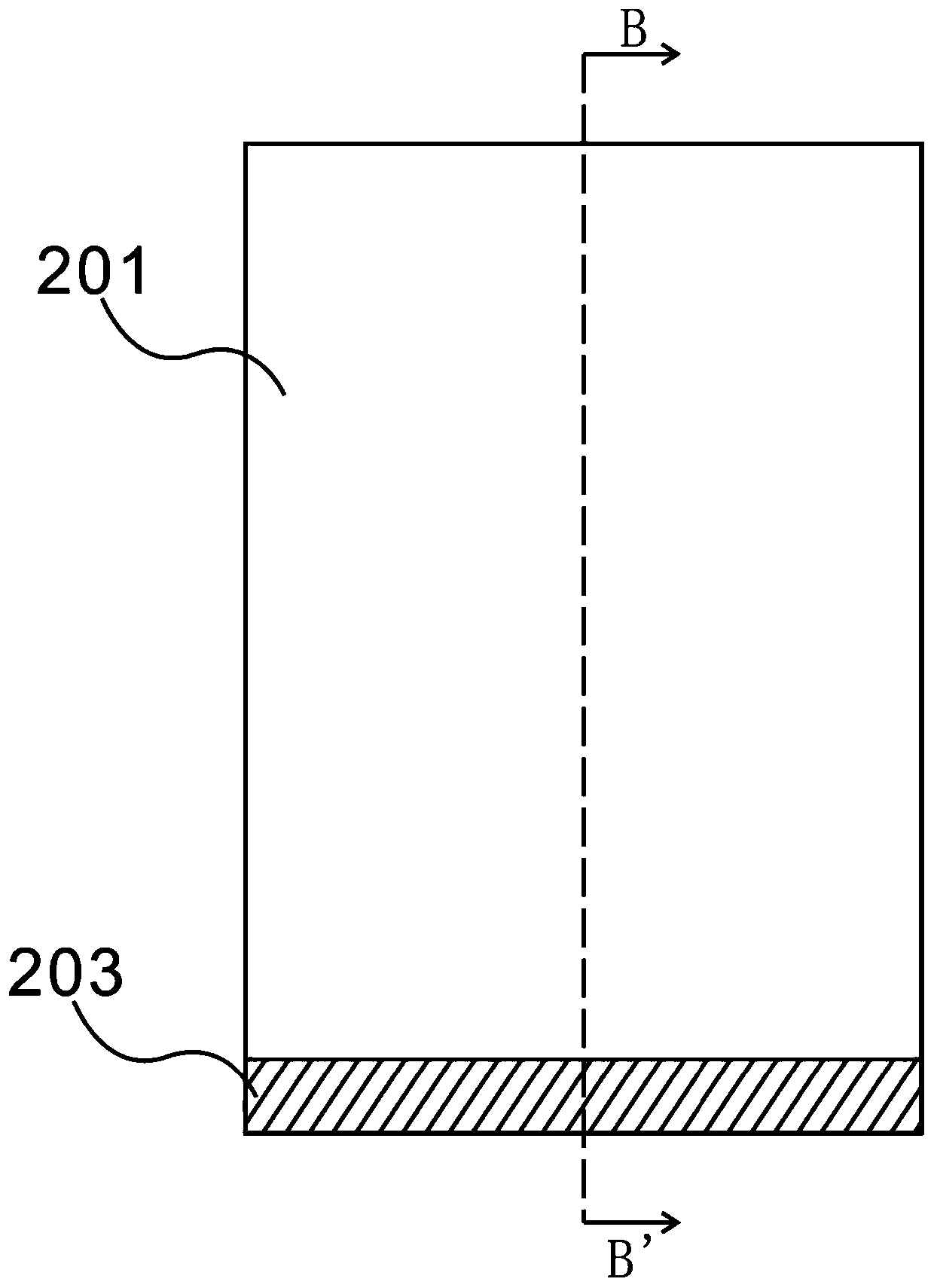

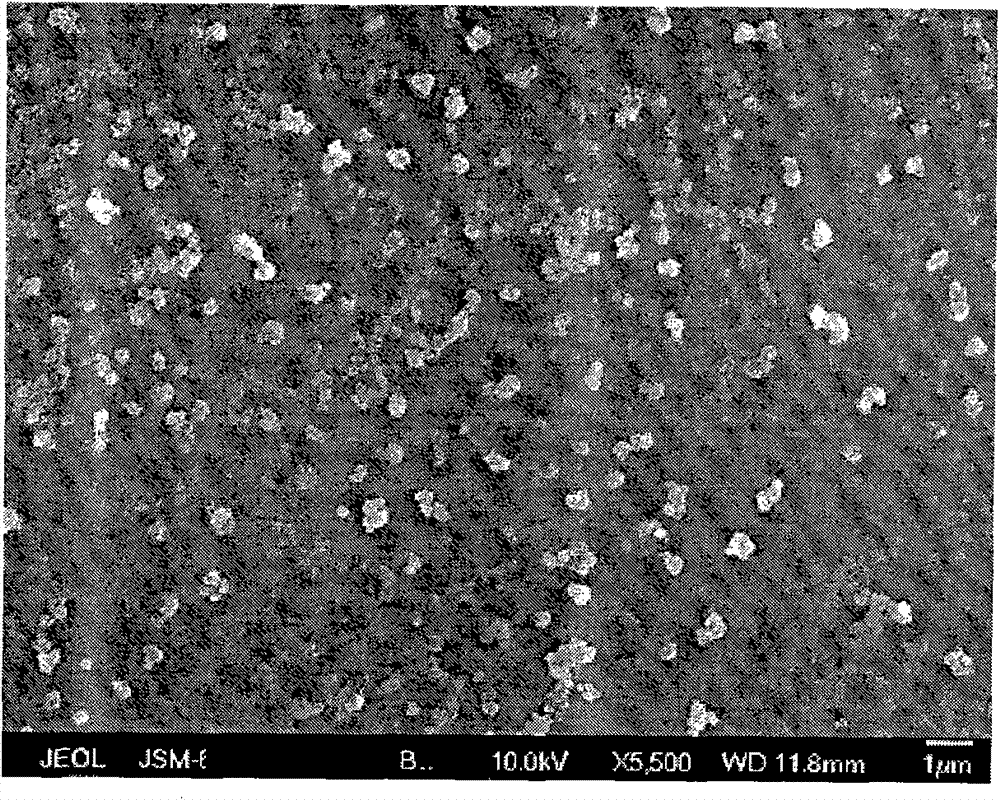

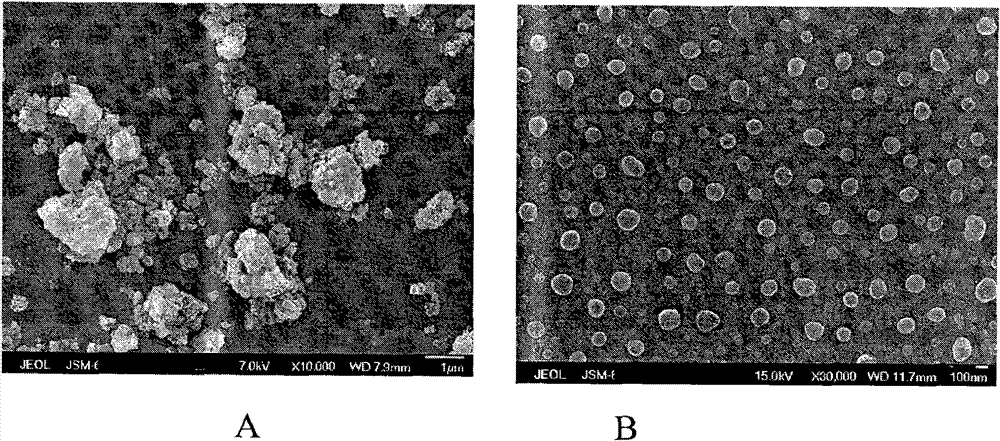

Preparation method of stable double-particle system electronic ink display solution

InactiveCN101870827BGood colorImprove stabilityOrganic dyesPigment treatment with macromolecular organic compoundsDispersion stabilityDisplay contrast

The invention relates to a preparation method of a stable double-particle system electrophoretic display solution for electronic ink display. Pigment electrophoretic particles which have small particle diameter and good dispersibility can be obtained through recrystallization and surface modification, and the dispersion stability and the surface charge of the particles can be improved by adding charging agents and dispersing agents. The particle diameter of the electrophoretic particles in the invention can reach 30-350nm. Two single-particle electrophoretic display solutions are prepared in proper proportions, and proper stabilizing agents and charging agents are added to obtain the double-particle system electrophoretic display solution, thereby obviously improving the display contrast,shortening the response time (the response time is 0.8-2s), obviously improving the stability of the electrophoretic display solution (the sedimentation rate is 8-14% after standing for 30d), and creating the condition for realizing industrial application.

Owner:BEIJING UNIV OF CHEM TECH

Double-sided organic light emitting diode (OLED) display and package method thereof

ActiveCN106783914AProtect from high temperature damageImprove display lifeSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The invention provides a double-sided organic light emitting diode (OLED) package structure. The double-sided OLED package structure comprises an upper plate body and a lower plate body, wherein bending structures are arranged at edges of the upper plate body and the lower plate body, and package adhesives are arranged at inner sides of the bending structures so that side parts of a first substrate and a second substrate are respectively and correspondingly connected with the bending structures by the package adhesives. The double-sided LED package structure has the beneficial effects that the package adhesives are arranged at side parts of package covers and are far away from a light emitting surface, so that an organic light emitting layer is free from the damage of a high temperature, and the display lifetime is prolonged; and the side parts of the package covers can be thinned so as to be beneficial for reducing the frame width of a double-sided display.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A pixel unit, its manufacturing method, and display device

ActiveCN105355644BAvoid problems that increase evaporation costsImprove display lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic electroluminescence

The invention discloses a pixel unit, a manufacturing method thereof, and a display device, and relates to the field of display technology, in order to solve the problem of increasing the evaporation cost caused by multiple times of evaporation when manufacturing a white sub-pixel unit. The white sub-pixel unit in the pixel unit includes: a white light carrier injection layer formed in the same patterning process as the red light carrier injection layer, the green light carrier injection layer and the blue light carrier injection layer, and Red light carrier transport layer, green light carrier transport layer and blue light carrier transport layer are formed in the same patterning process, white light carrier transport layer, organic electroluminescent material layer corresponding to other sub-pixel units A white light organic electroluminescent material layer formed in the same patterning process. The pixel unit provided by the invention is used in OLED display screens.

Owner:BOE TECH GRP CO LTD +1

A pixel circuit, its driving method, display panel and display device

ActiveCN111261102BSolve afterimage problemImprove display lifeStatic indicating devicesComputer hardwareDisplay device

The invention discloses a pixel circuit, a driving method thereof, a display panel and a display device. The pixel circuit includes: a data writing module, a switch control module, a reset module, a light-emitting control module, a first light-emitting device, and a second light-emitting device , and a drive control module; by setting the first light-emitting device and the second light-emitting device, and the second electrode of the first light-emitting device is coupled to the first electrode of the second light-emitting device, the first electrode of the first light-emitting device and the second The second electrode of the light-emitting device is coupled, and through the cooperation of the data writing module, the switch control module, the reset module, the light-emitting control module and the driving control module, the time-sharing display of the first light-emitting device and the second light-emitting device can be controlled, which can avoid Static display for a long time, so as to avoid the afterimage problem of the OLED display, prolong the display life of the OLED display, and improve the display performance of the OLED display.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

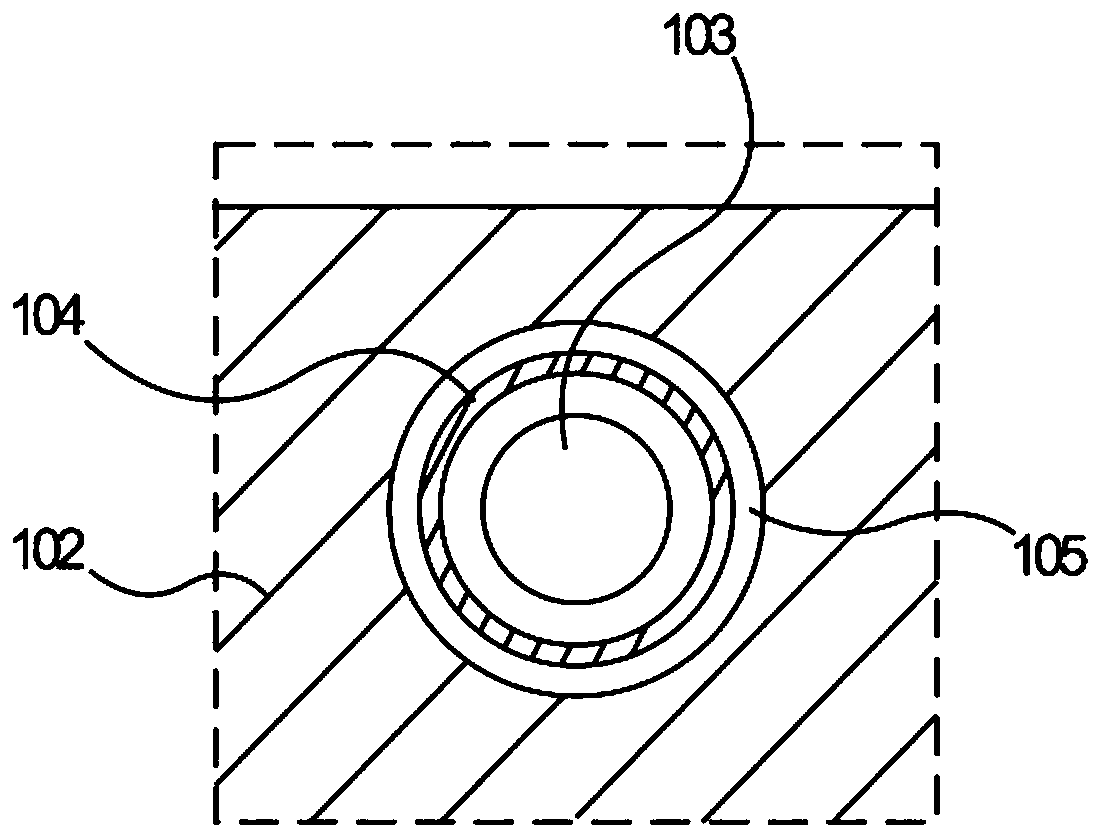

Display screen and electronic equipment

ActiveCN112188060AImprove display lifeHigh impedanceTelevision system detailsDigital data processing detailsTransmittanceEngineering

The invention discloses a display screen and electronic equipment. According to the invention, a transparent and conductive material is set in a first region as a wire corresponding to a light-emitting unit, the wire material of a second region is different from the wire material of the first region, and the impedance of the first material is higher than the impedance of the second material, so the first area and the second area have different light transmittance, and the purpose of prolonging the display life of the first area is achieved; and meanwhile, the light transmittance of the first area is higher than the light transmittance of the second area, and the first wire of the first area is made of a transparent material, so when image acquisition equipment arranged below the first areaneeds to perform image acquisition, a good image acquisition effect can be achieved.

Owner:LENOVO (BEIJING) LTD

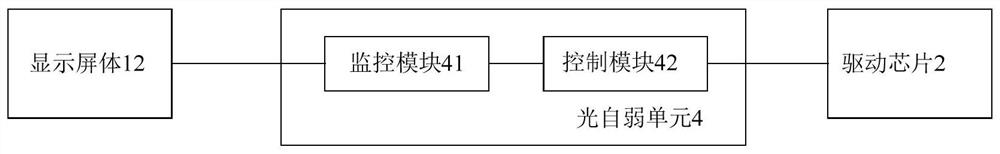

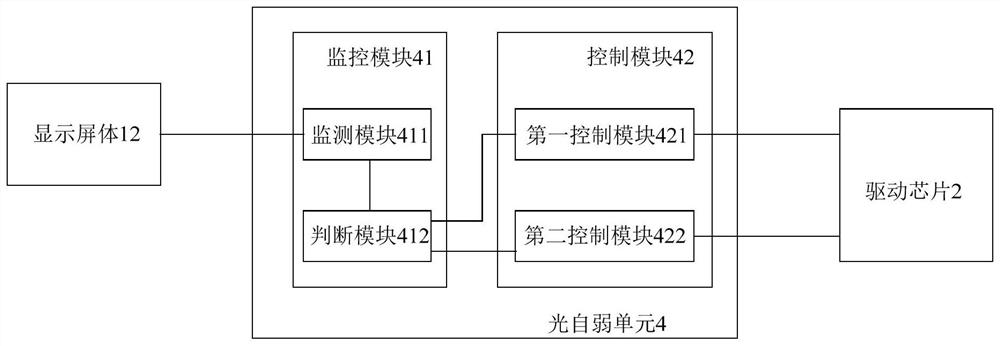

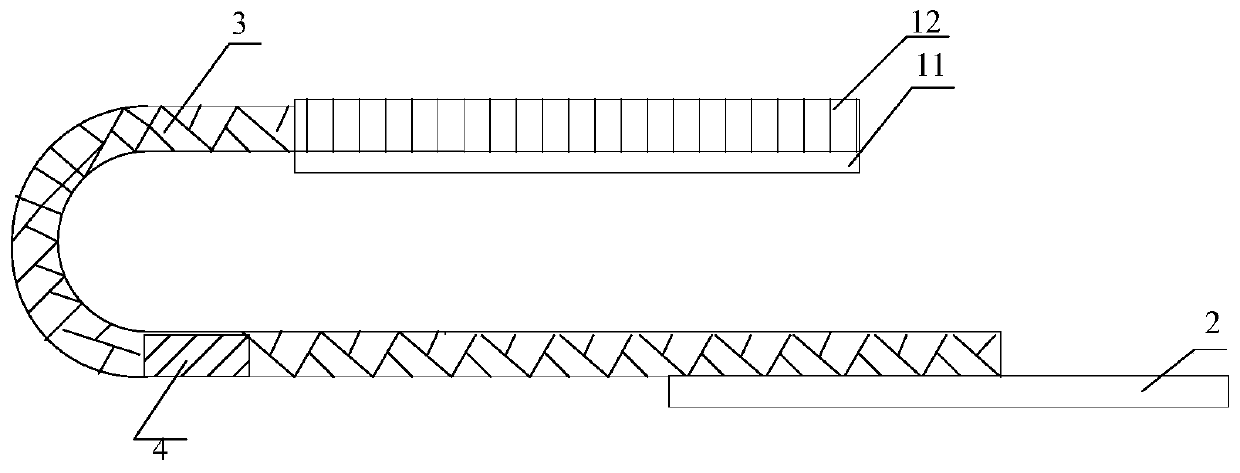

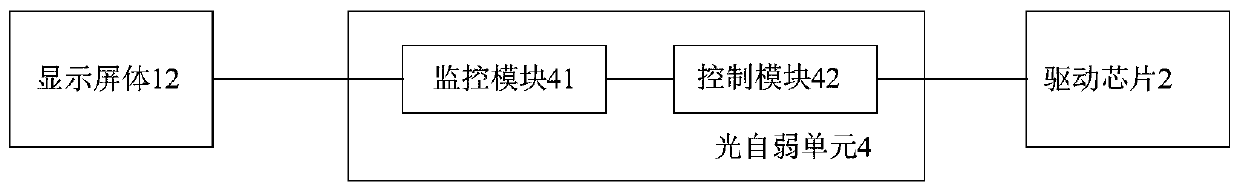

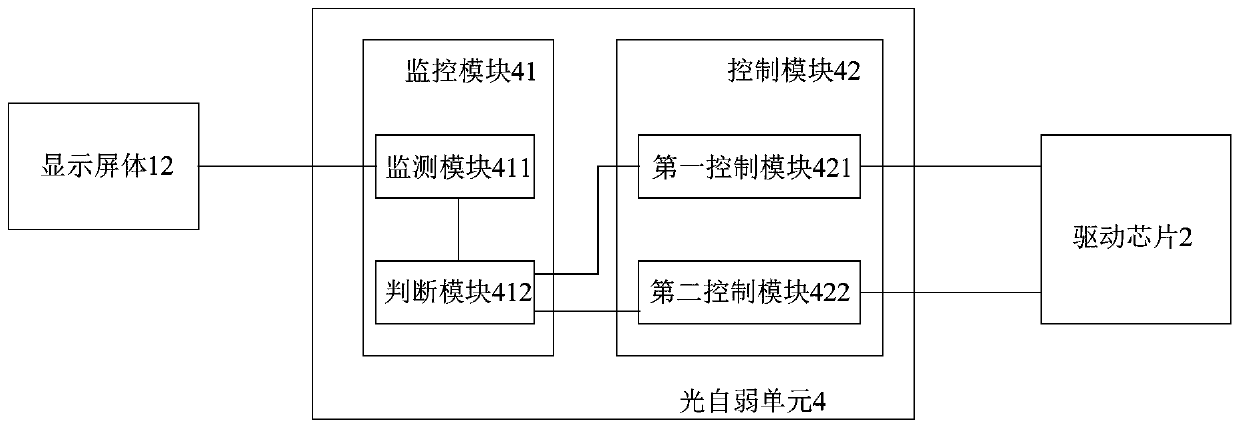

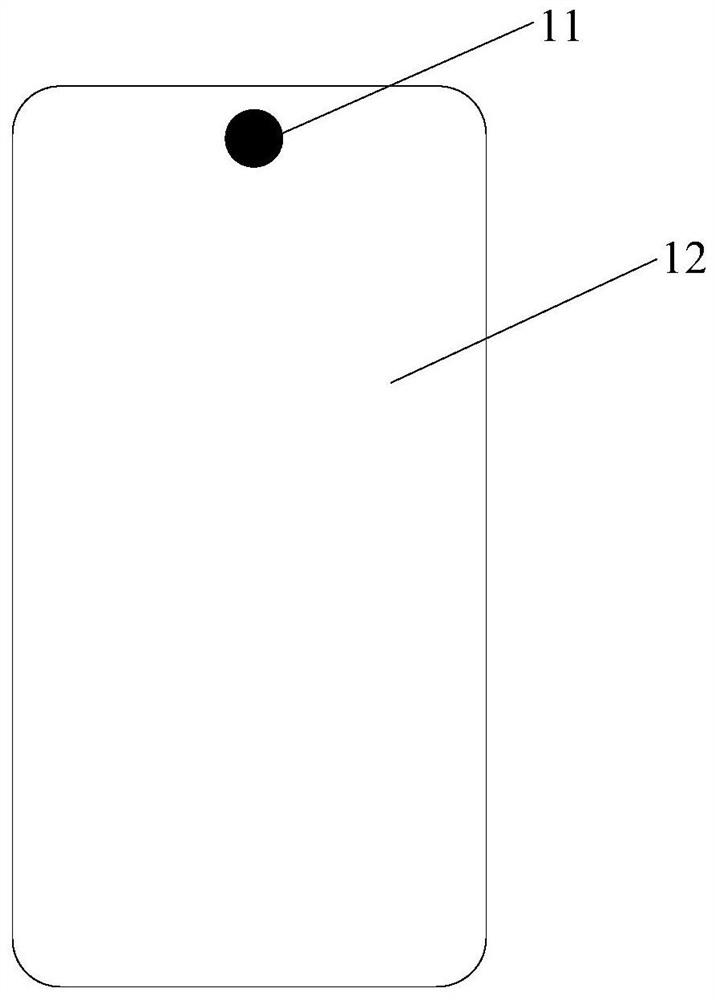

A display device and a method for adjusting display brightness of the display device

ActiveCN110599956BReduce display brightnessReduce luminous intensityStatic indicating devicesComputer hardwareMedicine

The invention provides a display device and a method for adjusting the display brightness of the display device, which solves the technical problem of low lifespan of the display device in the prior art. The display device provided by the embodiment of the present invention includes a light self-weakening unit arranged on a driving chip or a flexible circuit board, wherein the light self-weakening unit can automatically reduce the display brightness of the display screen, so when the display body in the display device can The actual display situation automatically reduces the display brightness, thereby reducing the luminous intensity of the display body during continuous display, thereby improving the display life of the display body.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

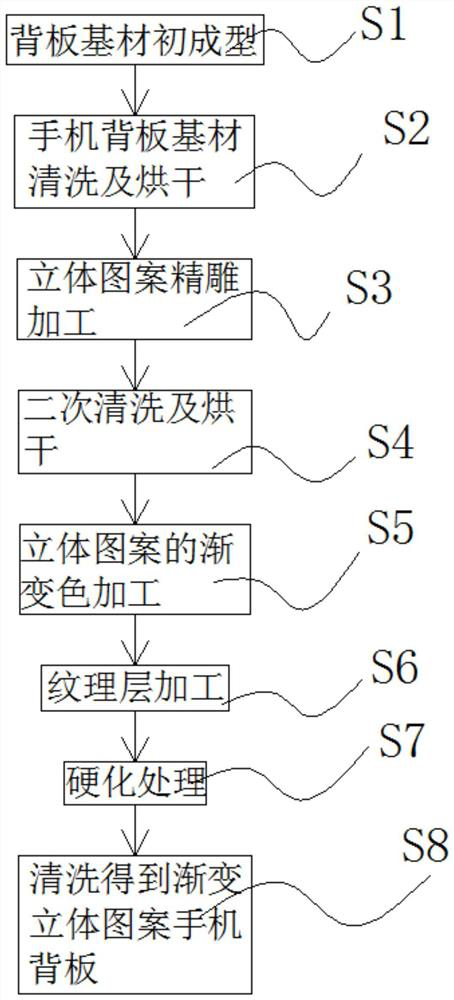

Preparation method of gradient three-dimensional pattern mobile phone backboard

PendingCN114228384AImprove appearance display effectEasy to viewDecorative surface effectsSpecial ornamental structuresComputer graphics (images)Engineering

The invention discloses a preparation method of a gradient three-dimensional pattern mobile phone backboard. The preparation method comprises the following steps: S1, pre-forming a backboard substrate; s2, cleaning and drying the mobile phone backboard base material; s3, carrying out fine carving processing on the three-dimensional pattern; s4, carrying out secondary cleaning and drying; s5, carrying out gradient color processing on the three-dimensional pattern; s6, processing a texture layer; s7, carrying out hardening treatment; and S8, cleaning to obtain the gradient three-dimensional pattern mobile phone backboard. The first groove, the first step protrusion, the second step protrusion and the center protrusion are arranged to form the step protrusion structure, and the first pattern, the second pattern and the logo pattern are finely carved on the surface of the step protrusion structure, so that the three-dimensional pattern is obtained; and then the first gradient color layer is formed on the surface of the first pattern, the second gradient color layer is formed on the surface of the second pattern, and the logo gradient color layer is formed on the surface of the logo pattern, so that the mobile phone backboard has gradient color three-dimensional patterns, the appearance display effect of the mobile phone backboard is improved, and the ornamental value is improved.

Owner:SHENZHEN ATES SCI & TECH CO LTD

Display device and method for adjusting display brightness of display device

ActiveCN110599956AReduce luminous intensityImprove display lifeStatic indicating devicesDisplay deviceComputer engineering

The invention provides a display device and a method for adjusting the display brightness of the display device, which can solve the technical problem that in the prior art, the service life of a display device is short. The display device comprises a light self-weakening unit arranged on a driving chip or a flexible circuit board, the display brightness of the display screen can be automaticallyreduced by the light self-weakening unit, so that the display brightness of the display screen body in the display device can be automatically reduced according to the actual display condition, the luminous intensity of the display screen body during continuous display can be reduced, and the display life of the display screen body is prolonged.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Display screen and electronic device

ActiveCN112188060BImprove display lifeHigh impedanceTelevision system detailsDigital data processing detailsTransmittanceEngineering

The present application discloses a display screen and an electronic device. By setting a transparent and conductive material in the first area as the wiring corresponding to the light-emitting unit, the wiring material in the second area is different from that in the first area, and The impedance of the first material is higher than that of the second material, so that the first area and the second area can have different light transmittances, and achieve the purpose of improving the display life of the first area. At the same time, due to the high light transmittance of the first area In the second area, and the first wiring in the first area is made of a transparent material, so that the image acquisition device disposed under the first area can have a better image acquisition effect when image acquisition is required.

Owner:LENOVO (BEIJING) LTD

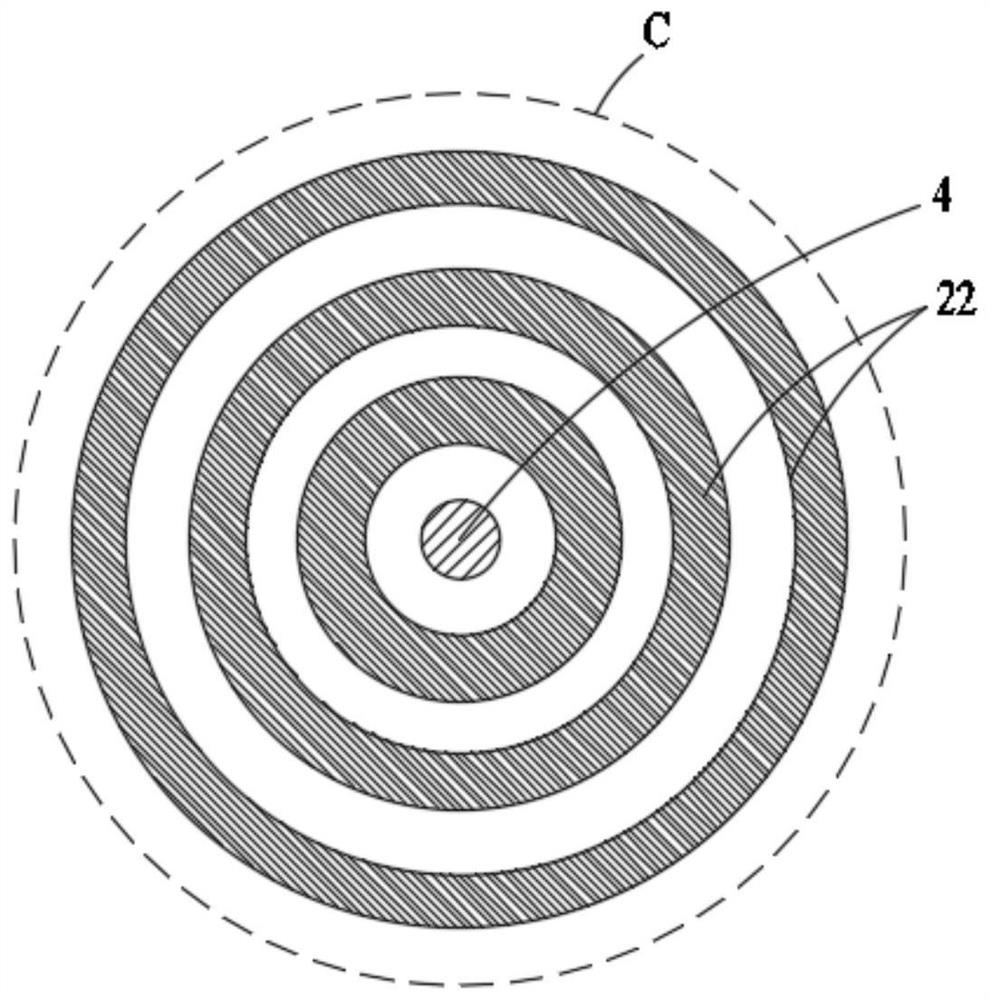

oled display panel

ActiveCN109671864BImprove display lifeAffect display qualitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention provides an OLED display panel, the display area of the OLED display panel is formed with a through hole and a water blocking structure for preventing the through hole from invading water vapor; the beneficial effect is: compared with the existing OLED display panel, this According to the invention, a water-blocking wall is provided at the cutting part of the OLED display panel, so as to isolate the light-emitting device at the cutting part from the water vapor of the light-emitting device in the display area, thereby protecting the light-emitting device in the panel from water vapor erosion, and prolonging the display life of the OLED display panel; It solves the problem that in the existing special-shaped cutting technology in the screen, after the OLED display panel is cut, there is no encapsulation layer protection at the cutting place, thereby exposing the light-emitting device, and water vapor invades the OLED display panel from the cutting place, causing damage to the light-emitting device, which in turn affects the display of the entire panel quality.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com