Preparation method of stable double-particle system electronic ink display solution

An electronic ink and dual-particle technology, which is applied in the processing of dyed polymer organic compounds, organic dyes, and fibrous fillers, can solve the problems of long particle response time, limited display color, and low display contrast, and achieve particle response time. Shorten, prolong display life, good color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] 2. Preparation of color electrophoretic display solution

[0024] (1) Dissolve the pigment in the solvent to make a solution of 3g / L~15g / L; (2) Measure 50~300mL of anti-solvent and add modifier; (3) Put ( 1) Add the medium solution dropwise to the anti-solvent, and stir for 10-40 minutes; (4) Measure 5-20 mL of dispersion medium and add it to the (3) solution, and stir for 10-30 minutes; (5) Stand to separate layers, and remove the lower layer Solution, add stabilizer or charging agent, use KQ5200DE CNC ultrasonic cleaner to sonicate for 10-30min, the ultrasonic parameters are set as: ultrasonic pulse is 2sec on, 1sec off; ultrasonic amplitude is 100%, and the colored electrophoretic particles can be obtained .

[0025] The pigment described in the above (1) step can be toluidine red, phthalocyanine blue, Yingli blue, benzidine yellow G-R, permanent orange RL, benzidine yellow G, iron oxide red, phthalocyanine green, quinacridone purple 4R, naphthol green B, medium ch...

Embodiment 1

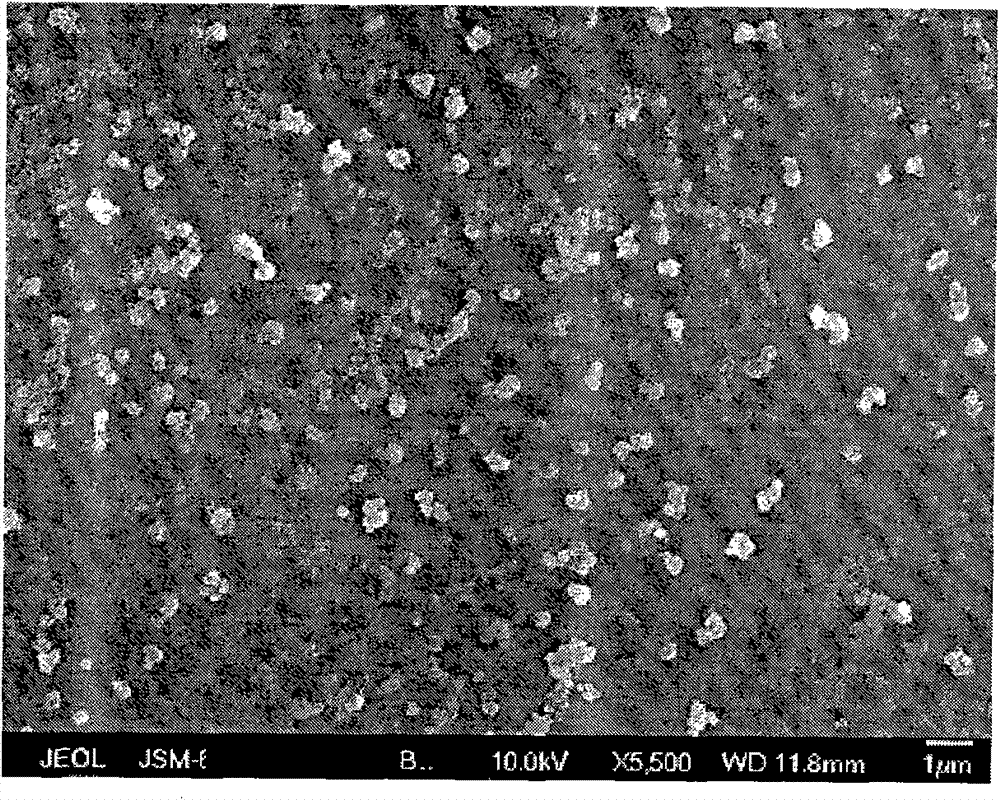

[0035] Preparation of green and white two-particle electrophoresis display solution

[0036] (1) Weigh 0.04g phthalocyanine green and dissolve in 5mL concentrated sulfuric acid (mass concentration: 98%); (2) Weigh 0.16g CTAB and 0.04g PVP and add them to a mixed solution of 50mL water and 50mL isopropanol , stir, and add it into a 250mL three-necked flask after it is completely dissolved, control the temperature of the water bath at 25°C, and the stirring speed at 900rpm; (3) Add the phthalocyanine green-concentrated sulfuric acid solution in (1) dropwise to the three-necked flask in (2) Carry out recrystallization in the bottle and modify the surface of the particles, stir for 30 minutes; (4) Measure 8 mL of tetrachlorethylene and add it to the suspension in (3), stir for 20 minutes; The solution was added with 0.12g Span80, stirred for 60min, and ultrasonically treated with a KQ5200DE digitally controlled ultrasonic cleaner for 10min. The ultrasonic parameters were set as fo...

Embodiment 2

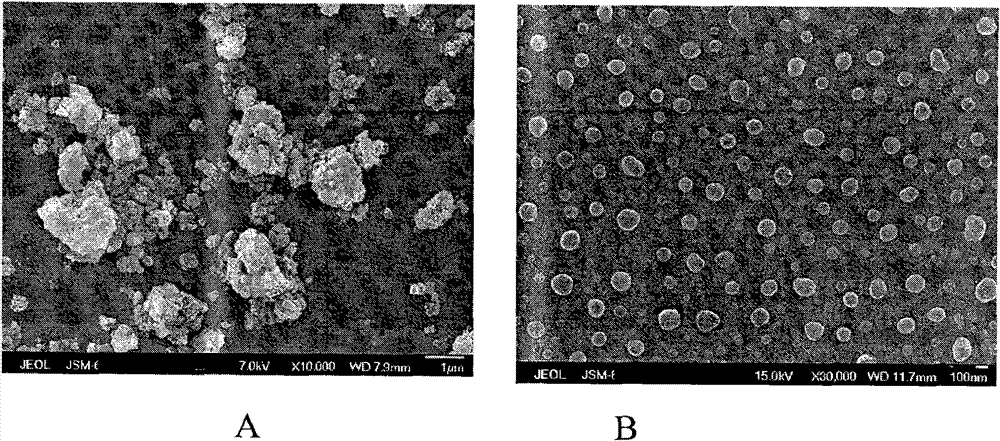

[0040] Preparation of Green-black Double Particle Electrophoresis Display Solution

[0041] (1) Weigh 0.04g phthalocyanine green and dissolve in 5mL concentrated sulfuric acid (mass concentration is 98%); (2) Weigh 0.2g SDS and 0.04g PVP, add to the mixed solution of 50mL water and 50mL isopropanol , stir, and add it into a 250mL three-necked flask after it is completely dissolved, control the temperature of the water bath at 25°C, and the stirring speed at 800rpm; (3) Add the phthalocyanine green-concentrated sulfuric acid solution in (1) dropwise to the three-necked flask in (2) Carry out recrystallization in the bottle and modify the surface of the particles, stir for 30 minutes; (4) Measure 8 mL of tetrachlorethylene and add it to the suspension in (3), stir for 20 minutes; Add 0.1 g of Triton X-100 to the solution, stir for 60 minutes, and use a KQ5200DE digitally controlled ultrasonic cleaner to sonicate for 10 minutes. The ultrasonic parameters are set as follows: ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com