Preparation method of OLED hybrid display panel, and display panel

A display panel and LED chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as poor heat dissipation performance, and achieve the effects of improving production efficiency and yield, improving efficiency and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

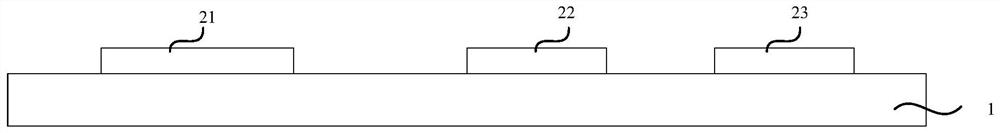

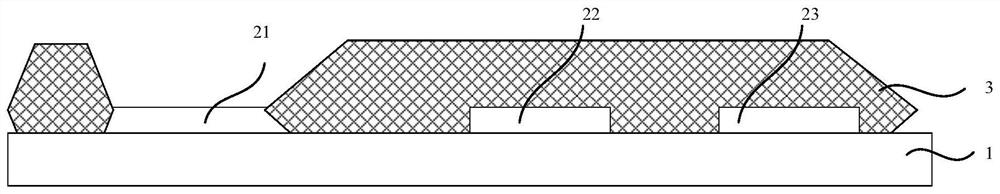

[0049] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0050] As mentioned in the background art above, since the LED chips generate a certain amount of heat during operation, the existing Micro-LED color display panels have poor heat dissipation performance. In view of the above technical problems, the embodiments of the present invention provide the following technical solutions:

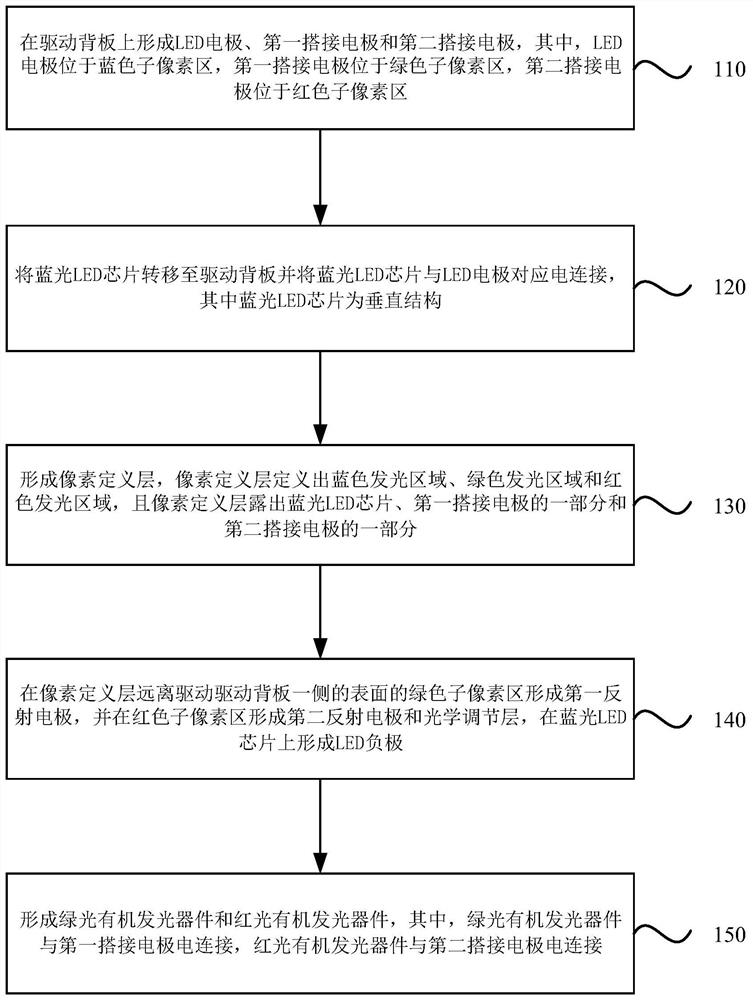

[0051] figure 1 It is a schematic flowchart of a method for manufacturing an OLED hybrid display panel provided by an embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com