A pixel unit, its manufacturing method, and display device

A pixel unit and sub-pixel unit technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, diodes, etc., can solve the problems of increasing evaporation costs and achieve the effect of improving display life and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

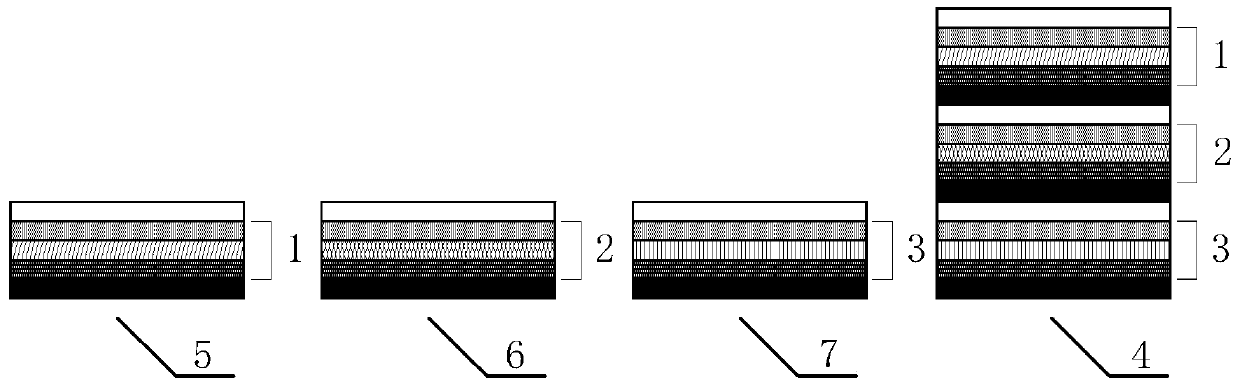

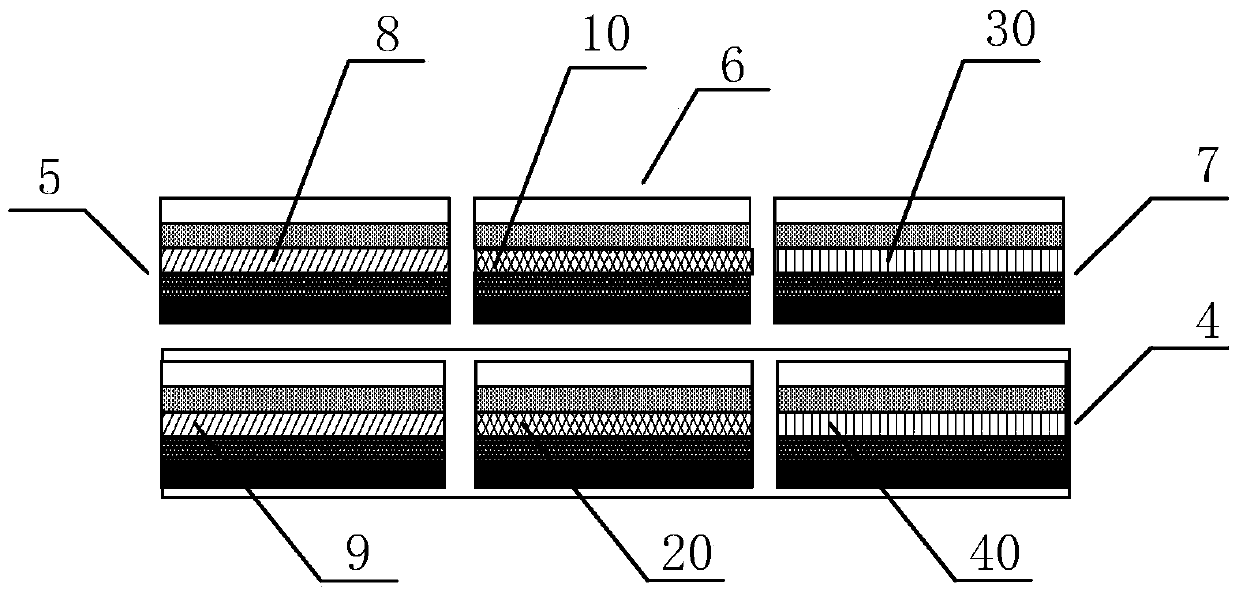

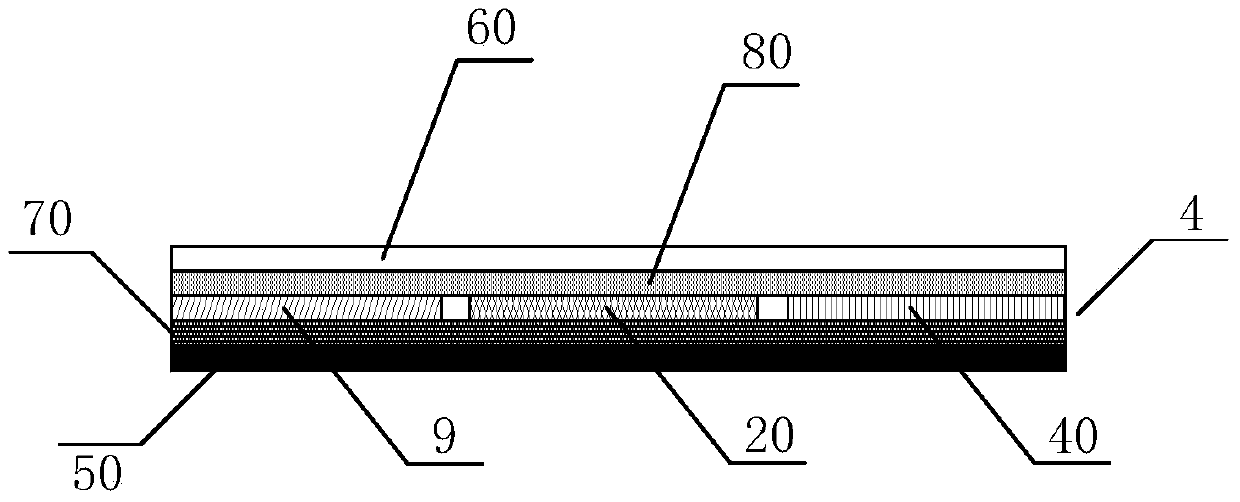

[0061] See Figure 5 , when And When For example, in this case, X R : X G : X B : (W R +W G +W B )=3:3:3:3=1:1:1:1, namely X R =X G =X B =(W R +W G +W B ); Therefore, when the same driving voltage is applied to each sub-pixel unit, the corresponding light brightness of each sub-pixel unit is the same, so that the light-emitting brightness of the pixel unit composed of it is more uniform.

Embodiment 2

[0063] See Image 6 , when 时,X R : X G : X B : (W R +W G +W B )=1:1:1:3, that is In this case, the area of the organic electroluminescent material layer corresponding to the red sub-pixel unit 5, the green sub-pixel unit 6 and the blue sub-pixel unit 7 is equal, and the organic electroluminescent material layer corresponding to the white sub-pixel unit 4 The area is relatively large. Therefore, when the same driving voltage is applied to the red sub-pixel unit 5, the green sub-pixel unit 6 and the blue sub-pixel unit 7, the red sub-pixel unit 5, the green sub-pixel unit 6 and the blue sub-pixel unit The brightness of the light emitted by the pixel unit 7 is the same, and more uniform color display can be realized after mixing these lights; and when the driving voltage is applied to the white sub-pixel unit 4, the brightness of the white light emitted by the white sub-pixel unit 4 is relatively high.

Embodiment 3

[0065] See Figure 7 , when When For example, in this case, X R : X G : X B : (W R +W G +W B )=4:1:1:6. Compared with the case of the first embodiment, the area of the organic electroluminescent material layer corresponding to the white sub-pixel unit 4 is larger. When the driving voltage is applied to the white sub-pixel unit 4, the white The sub-pixel unit 4 can also emit high-brightness white light, and this type of pixel unit can be used in medical equipment to give full play to its high-brightness display effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com