Over-roof prevention installation structure between photoelectric cabin and motion carrier

A technology of motion carrier and installation structure, applied in the direction of non-electric variable control, instrument, position/direction control, etc., can solve the problem of photoelectric stabilized platform over the top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

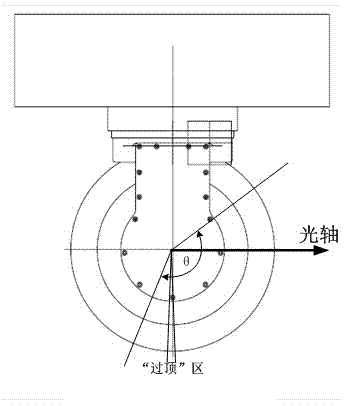

[0017] An embodiment of the anti-overhead installation structure between the photoelectric cabin body and the moving carrier, such as Figure 4 As shown, the anti-overhead installation structure between the photoelectric cabin body and the moving carrier includes a photoelectric cabin body 11 and a moving carrier 12 .

[0018] In this embodiment, the bottom of the moving carrier 12 is provided with an inclined surface that gradually slopes upward from the front to the rear relative to the horizontal plane, and the inclined surface is used for installing the photoelectric cabin body 11 .

[0019] The photoelectric cabin body 11 has an optical axis. In the present embodiment, the photoelectric cabin body 11 is installed vertically on the inclined surface of the moving carrier 12, thus making it tilt backward and forming an angle with the vertical plane. The included angle makes the overhead area of the photoelectric cabin body 12 avoided outside the working angle range of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com