A 3D Flexibility Modeling Method Applied to Spring Production and Assembly

A modeling method and three-dimensional flexible technology, applied in 3D modeling, special data processing applications, image data processing, etc., can solve the problems of easy errors in factory production, failure to realize separation spring simulation, etc., and achieve clear production and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Assume that the two ends of the spring wire are ground together tightly, the diameter of the spring wire is d=10mm, the free height H0=300mm, the two ends are closely ground together by m=3 / 4 turns, the total number of turns is N=15, and the number of effective turns is n=13.

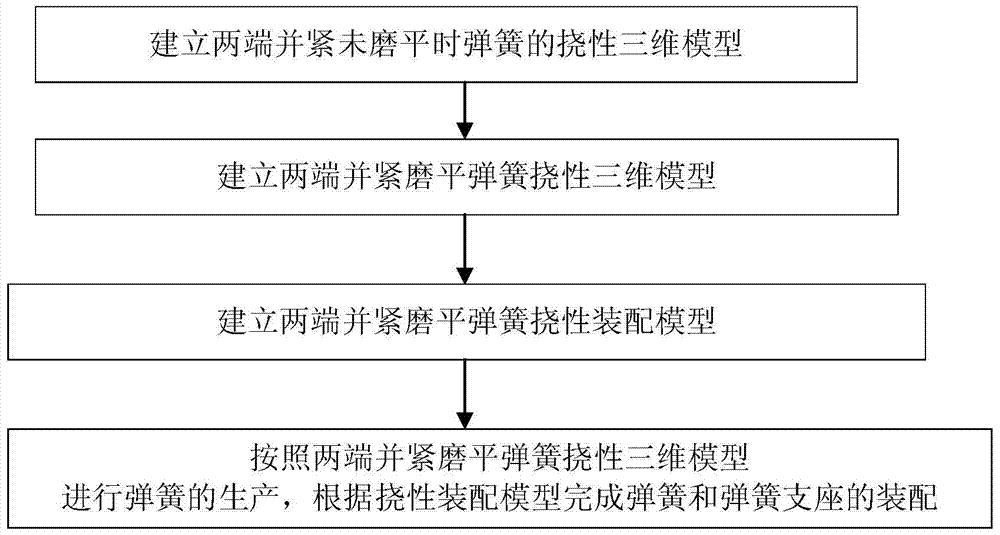

[0025] The flow chart of the present invention is as figure 1 As shown, the specific content is as follows:

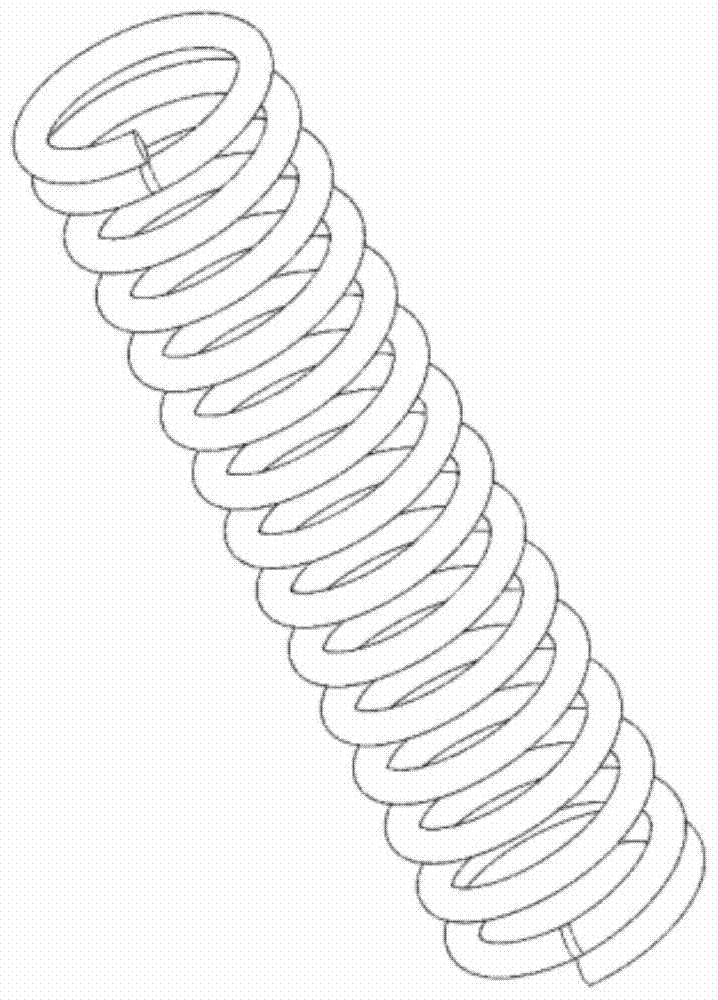

[0026] Using the helical scanning method to establish the flexible three-dimensional model of the spring when both ends are tight and not ground, such as figure 2 As shown, the height of the parallel tight part at both ends of the spring is d=6.25mm, the pitch of the parallel tight part at both ends p1=d=10mm, the transition part is 0.2mm, and the height L3 of the effective coil part satisfies

[0027] L3=H0-2×(1-m)×d-2×1 / 2×d (1)

[0028] The pitch p2 of the effective number of coils of the spring satisfies

[0029] p2=L3 / n (2)

[0030] According to the formula (1), the height L3 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com