Finite element and finite difference coupling method for fast calculating rolled piece section temperature

A finite difference and fast calculation technology, applied in the field of rolling, can solve problems such as unpredictable metal flow laws, difficult automation, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

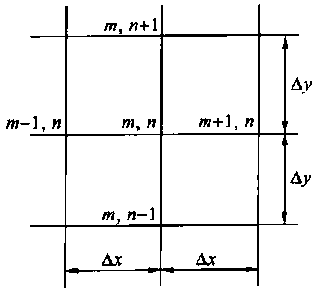

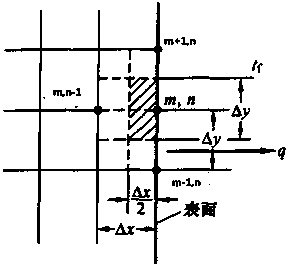

[0089] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

[0090] please see Figure 7 , is the technical layout diagram of the heavy rail production of the embodiment, and its rolling process is as follows: the billet is heated to the exit temperature in the heating furnace--high-pressure water dephosphorization--BD1 billet rolling--BD2 special-shaped rolling--water Mist cooling - universal rolling rough rolling - water mist cooling - universal rolling finish rolling - cooling bed cooling - straightening.

[0091] The rolling process can quickly calculate the section temperature of the rolled piece under certain pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com