Oval poking wheel sieve mechanism

A wheel sieve and ellipse technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of easy blockage of sieve holes, backward product technology, small sieving surface, etc., so as to avoid accumulation of materials in dead corners and improve sieving effect , easy to remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

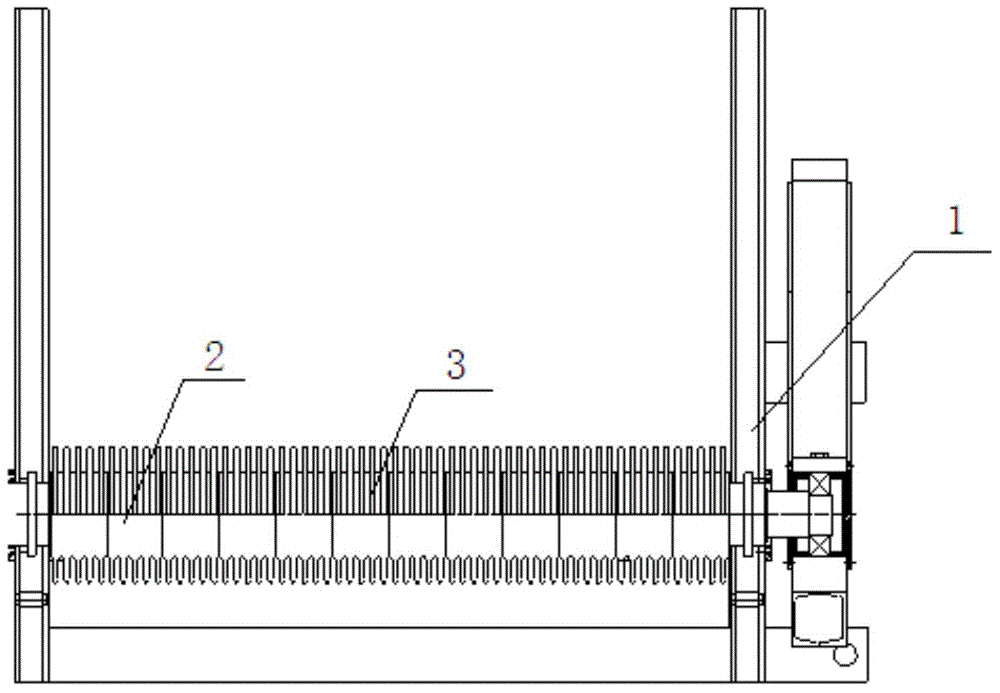

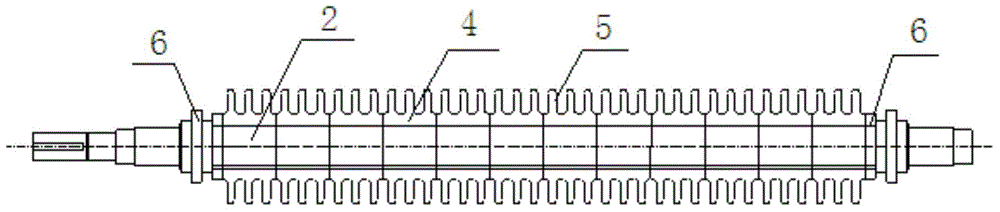

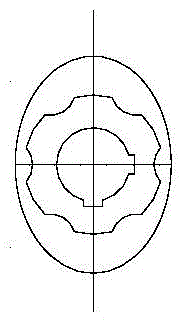

[0015] as attached Figure 1~3 As shown, a kind of ellipse wheel sieve mechanism comprises frame and several rotating shafts arranged side by side on the frame, the outer diameter of said rotating shaft is covered with a wheel whose section shape is ellipse, and the wheel consists of a plurality of The thumb wheel components are sequentially put on the rotating shaft and assembled, and are fixed by the attached wheels at both ends. A plurality of elliptical ring gears are arranged in the axial direction on the dial mechanism, and the ring gears on the dial mechanism corresponding to the adjacent rotating shafts are staggered and meshed with each other, and the gap between the meshing parts is preset, which is convenient for compounding materials of specified size to leak out.

[0016] According to the properties of different materials, selecting appropriate materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com