Production process of foamed reinforced rubber piece production device

A technology of reinforcing film and production device, which is applied in the direction of lamination device, layered product, paper/cardboard layered product, etc., can solve the problem of large thickness of reinforcing film, etc., and achieves easy frequency, easy disassembly, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

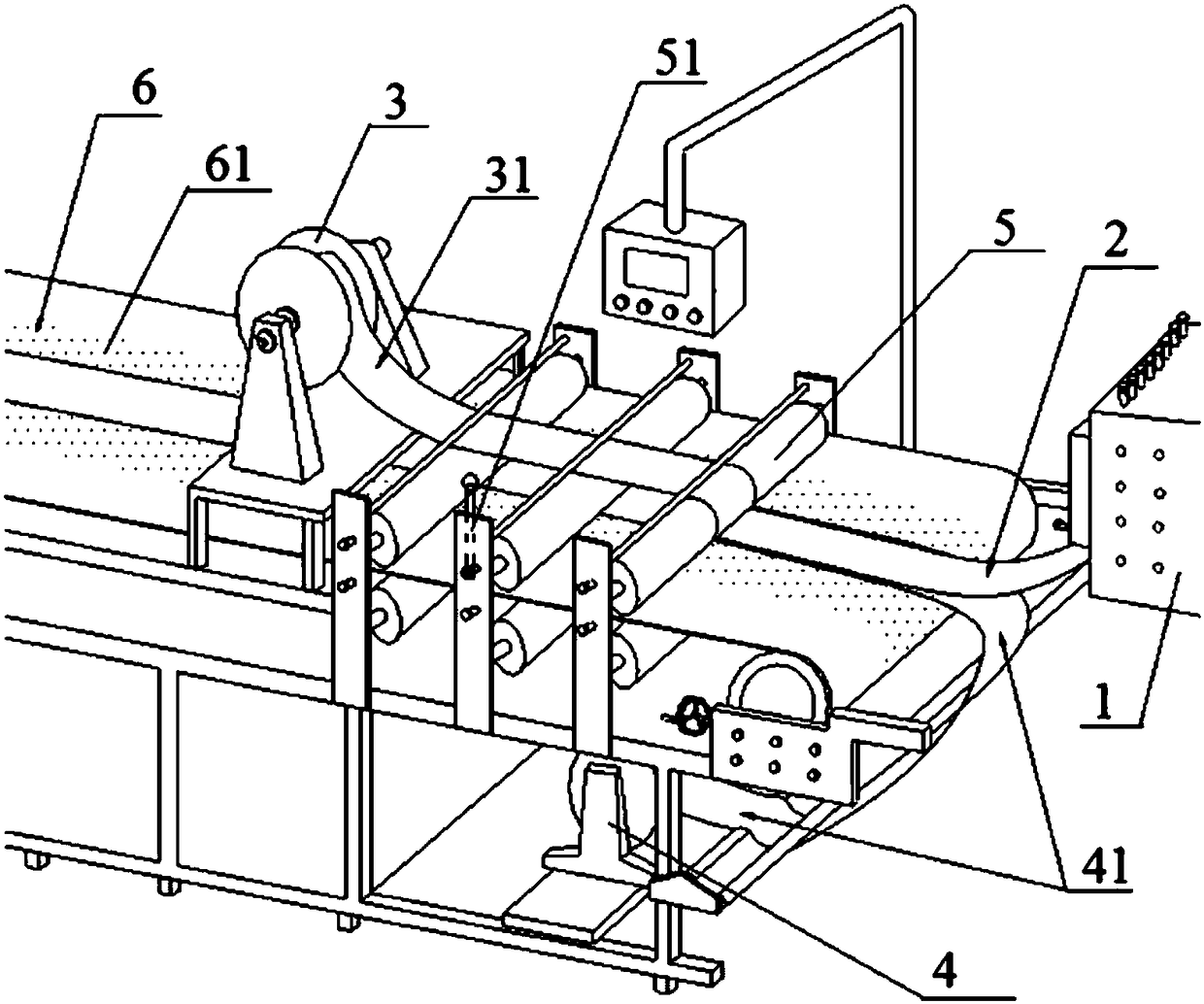

[0044] A kind of foam type reinforced film production device of the present embodiment, such as figure 2As shown, it includes a reinforced film extruder 1, a release paper roll frame 3, a cloth frame 4, a conveyor belt 6 and a cutting device 8, and also includes a squeeze roller 5, wherein: a reinforced film extruder 1, a conveyor belt 6 and a cutting device The device 8 is arranged in order according to the process, and the release paper roll frame 3 and the cloth frame 4 are fixed above and below the conveyor belt 6 respectively; The foamed reinforcing film 2 and cloth 41 extruded by the strong film extruder 1 are in upper, middle and lower layers to form a three-layer composite sheet 9 and move forward on the conveyor belt 6. The release paper 31 and the foamed reinforcing film The side of the film 2 in close contact has a striped rubber strip; the squeeze roller 5 is a double-roller structure up and down, and the distance from the beginning of the conveyor belt 6 is 50 cm...

Embodiment 2

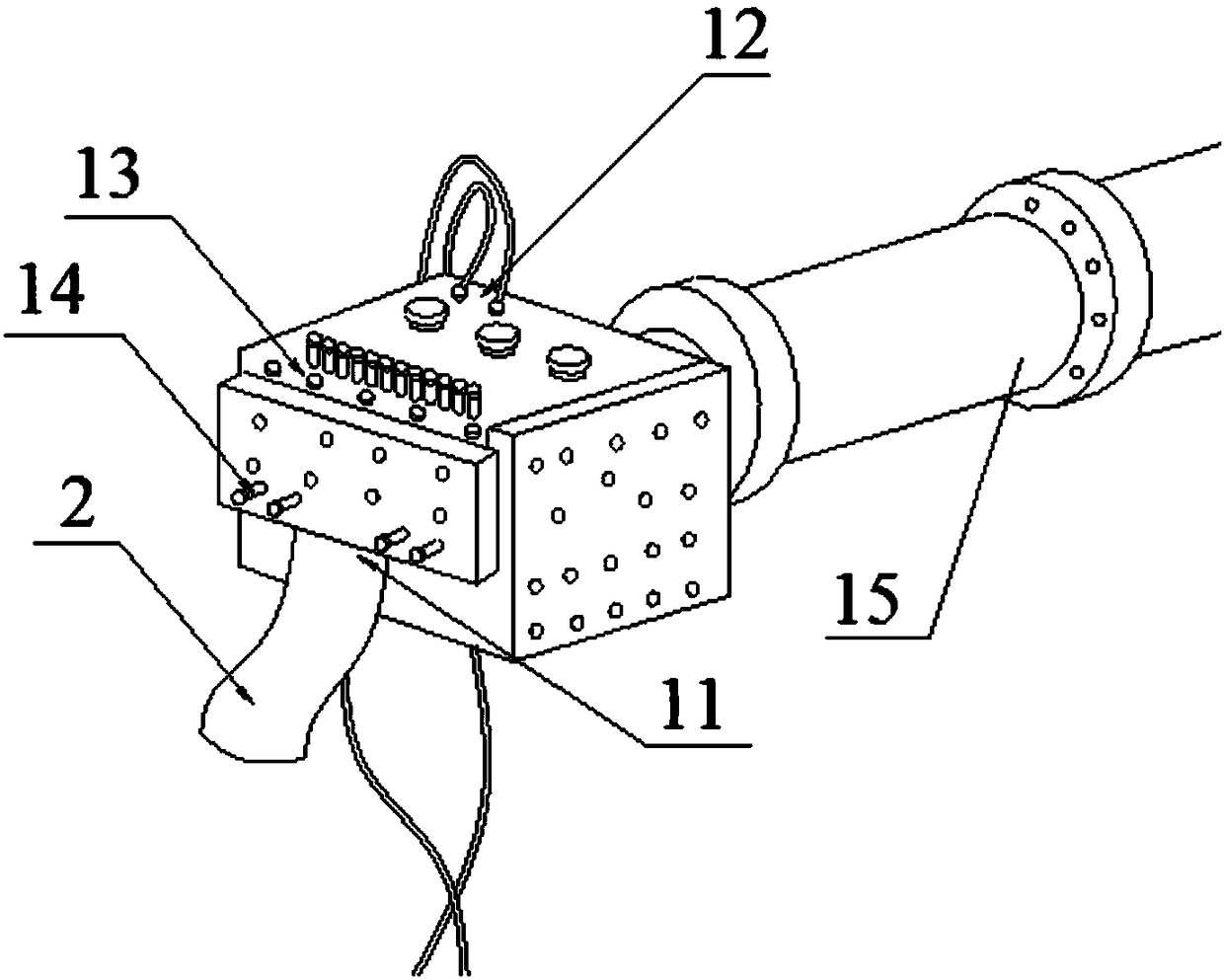

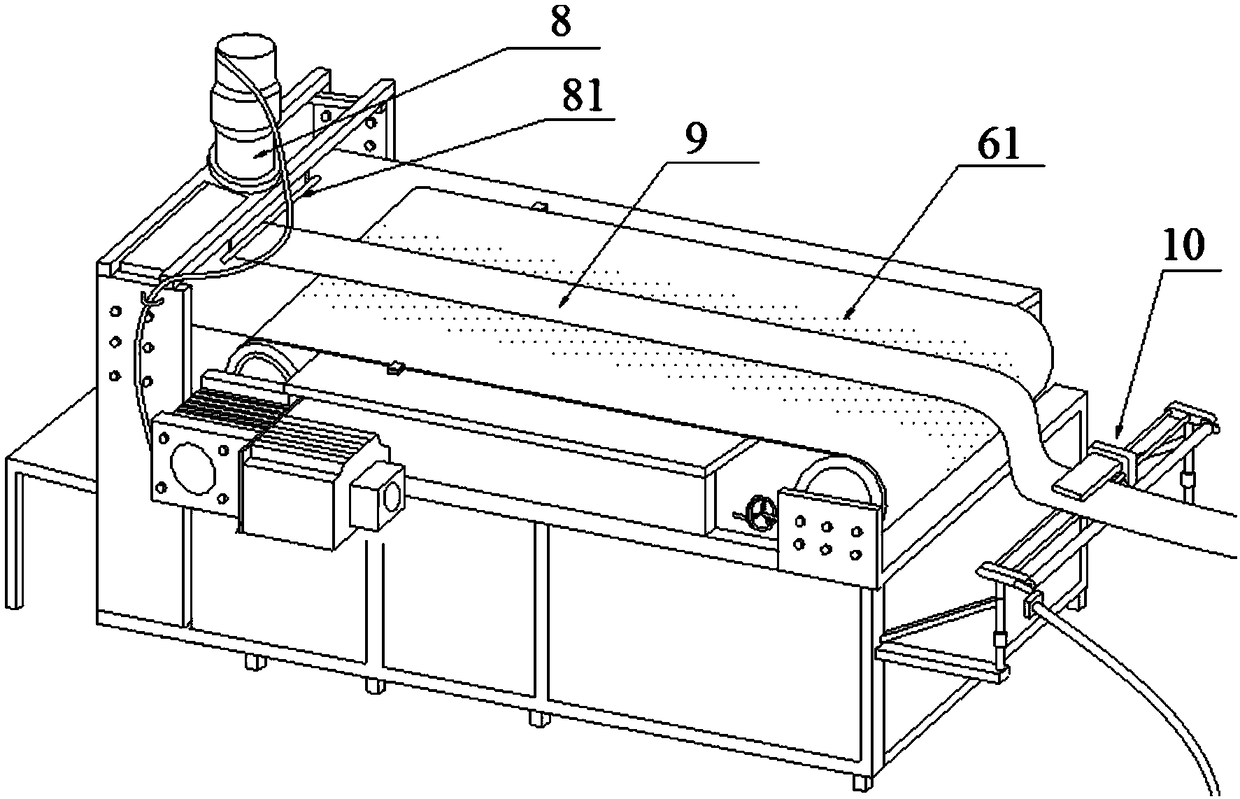

[0047] A foamed reinforced film production device in this embodiment has the same basic structure as that in Embodiment 1, and the improvement is that the reinforced film extruder 1 includes a discharge port 11, a heating mechanism 12, and a rubber material extruding mechanism 15 , also includes a film thickness adjustment mechanism 13 and a film width adjustment mechanism 14 arranged at the front end of the heating mechanism 12; the rubber extruding mechanism 15 is a barrel-shaped screw extruding mechanism. The cloth 41 is glass fiber cloth; the cutting device 8 is a cylinder type cutting, and the three-layer composite sheet 9 is cut by controlling the cutter 81 through the cylinder. Suction holes 61 are evenly distributed on the conveyor belt 6 . The squeeze roller 5 has a distance of 80 cm from the beginning of the conveyor belt.

[0048] A production process of a foamed reinforced film production device in this embodiment to produce foamed reinforced film, the steps are: ...

Embodiment 3

[0057] The basic structure of the foamed reinforced film production device of this embodiment is the same as that of Embodiment 2, and the improvement is that three pairs of extrusion rollers 5 are arranged side by side in parallel, and the three-layer composite sheet 9 is rolled three times. , and roll the foam-type reinforcing film 2 in the middle to a thickness of 1 mm. Both ends of the extrusion roller 5 are fixed with an extrusion adjustment mechanism 51; the diameter of the suction hole 61 is 1mm, the distance is 20mm, and it communicates with the negative pressure device. The squeeze roller 5 has a distance of 70 cm from the beginning of the conveyor belt.

[0058] When a kind of foamed reinforced film production device of this embodiment is used specifically, there are three pairs of squeeze rollers 5, and the three-layer composite sheet 9 is rolled three times, which ensures the uniformity of rolling and reduces the thickness of the reinforced film. The control is mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com