Sludge treatment device

A sludge treatment and treatment room technology, applied in grain treatment, metal processing, manufacturing tools, etc., can solve the problem of affecting the crushing effect of equipment, crushing efficiency, easy bonding on the surface of mechanical crushing bodies, and poor crushing efficiency. and other problems, to achieve high cutting efficiency, ensure the segmentation effect, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

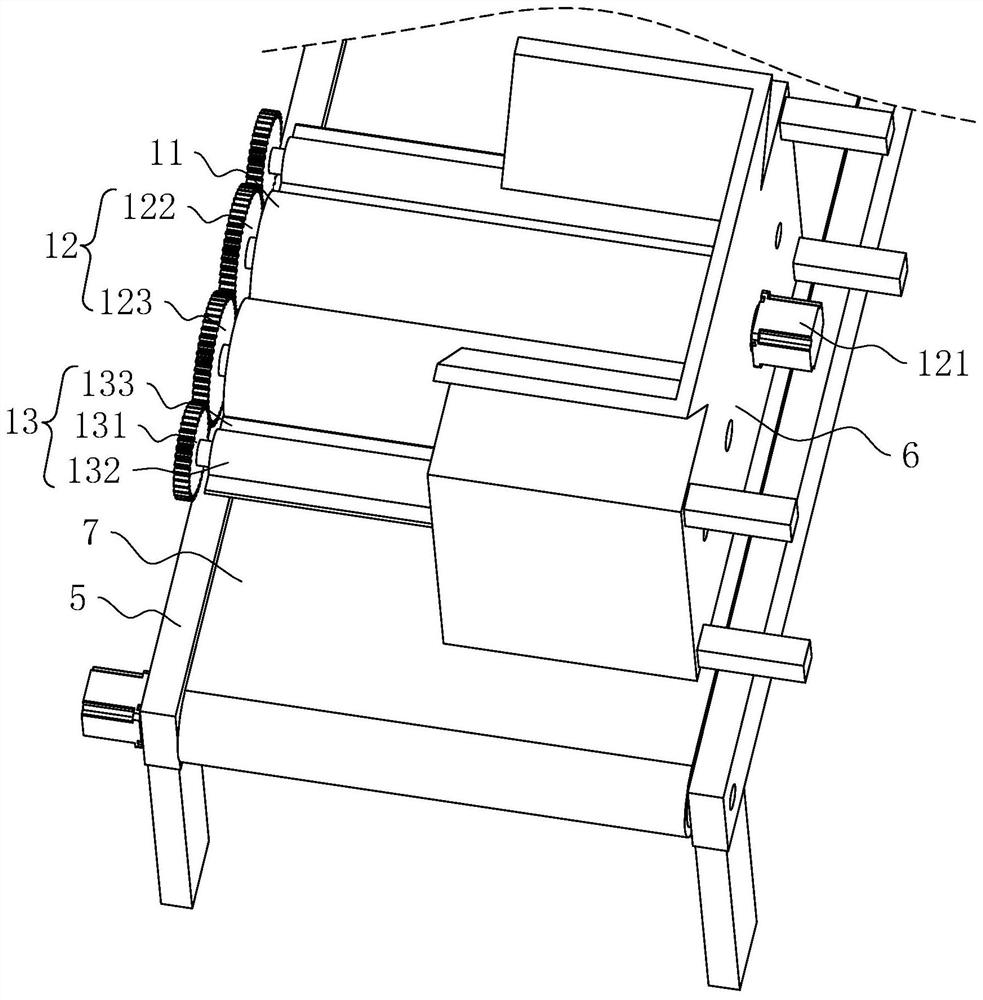

[0038] The following is attached Figure 1-6 The application is described in further detail.

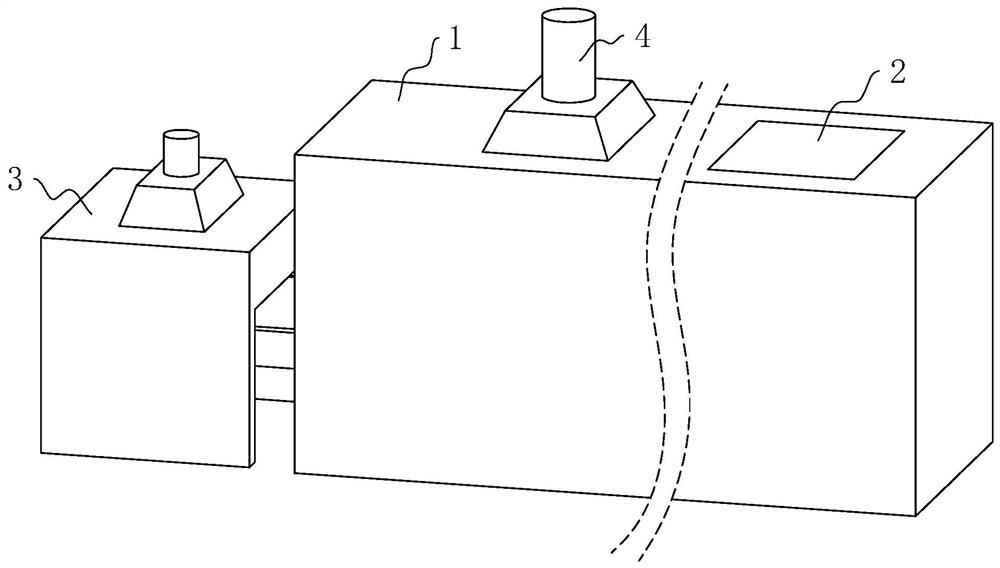

[0039] The embodiment of the present application discloses a sludge treatment device. refer to figure 1 , The sludge treatment device includes a treatment chamber 1, the upper end of the treatment chamber 1 is provided with a material inlet 2, one end of the treatment chamber 1 is provided with a drying box 3, and both the treatment chamber 1 and the drying box 3 are provided with a waste gas collection pipe 4. The sludge can be treated in the treatment chamber 1 and the drying box 3 , and the waste gas generated during the treatment process is discharged through the waste gas collection pipe 4 .

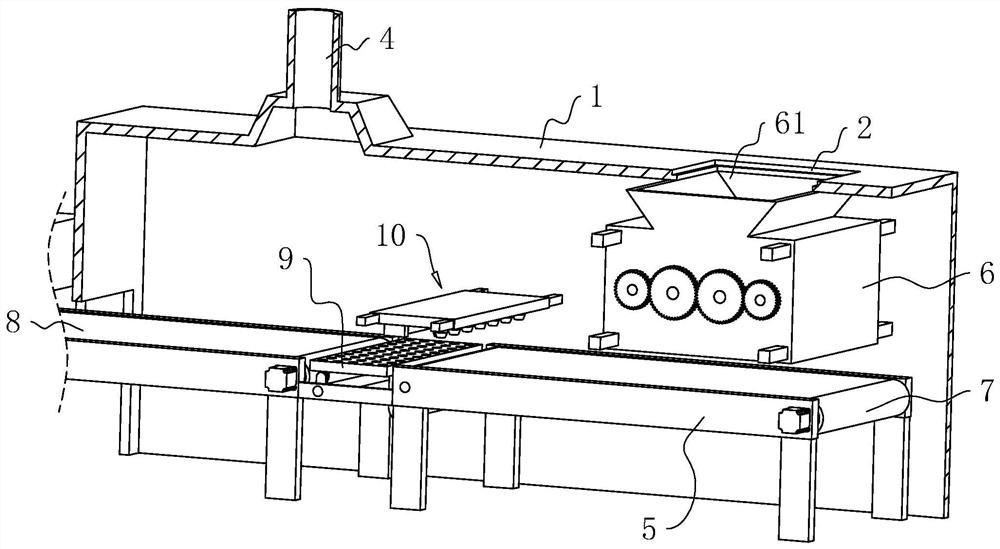

[0040] refer to figure 2, the processing chamber 1 is fixedly connected with a frame 5, and the processing chamber 1 is also fixedly connected with a pre-press box 6, the upper end of the pre-press box 6 is provided with a feed port 61, and the material inlet 2 is set corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com