A cutting knife installation shaft of an environmentally friendly flame retardant waterproof luggage fabric cutting machine

A bag fabric and cutting machine technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy deviation in adjustment, inconvenient adjustment, and affecting the cutting effect, so as to ensure the cutting effect and facilitate adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

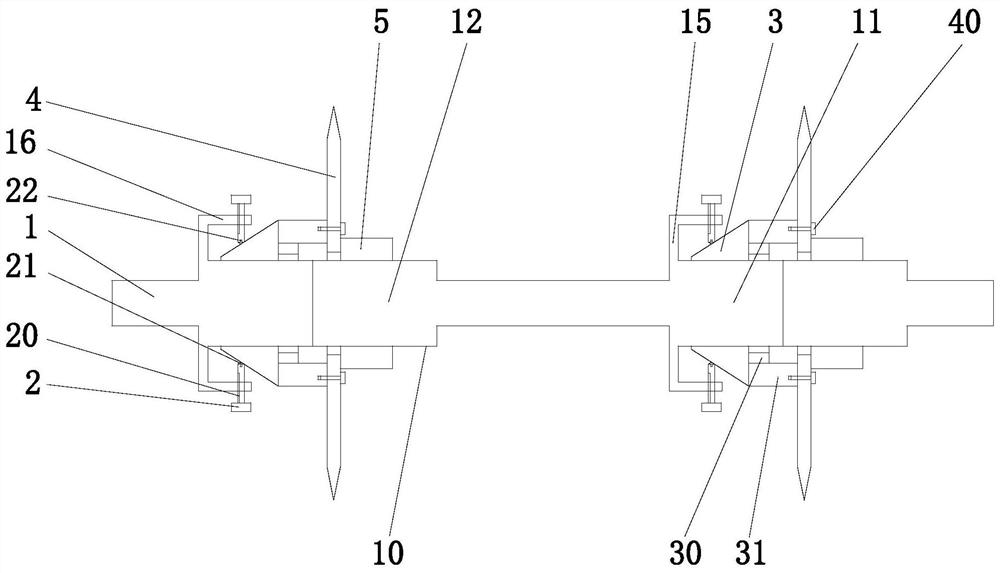

[0016] refer to figure 1 , a cutting knife installation shaft of an environmentally friendly flame-retardant and waterproof luggage fabric cutting machine according to the present invention, including a rotating shaft 1, a convex ring 10, a fixing plate 15, a mounting cylinder 16, an adjusting bolt 2, an adjusting cylinder 3, a limiting cylinder 31, and a blade 4 , limit nut 5, described rotating shaft 1 exterior is provided with several protruding rings 10, and protruding ring 10 is made up of threaded section 12 with external thread and polished rod section 11 without external thread, and polished rod section 11 ends are provided with There is a fixed plate 15, and a mounting cylinder 16 is fixed on the side of the fixed plate 15 close to the threaded section 12. The mounting cylinder 16 is sleeved outside the polished rod section 11, and several radially arranged adjusting bolts 2 are screwed on the mounting cylinder 16. The adjusting bolts The end of 2 is fixed with a coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com