Drying device

A technology of drying device and horizontal tube, which is applied to heating devices, preservation of seeds by drying, drying, etc., can solve the problems of low production efficiency, inability to meet the needs of production development, and large weather dependence, and achieves convenient operation, Simple structure and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

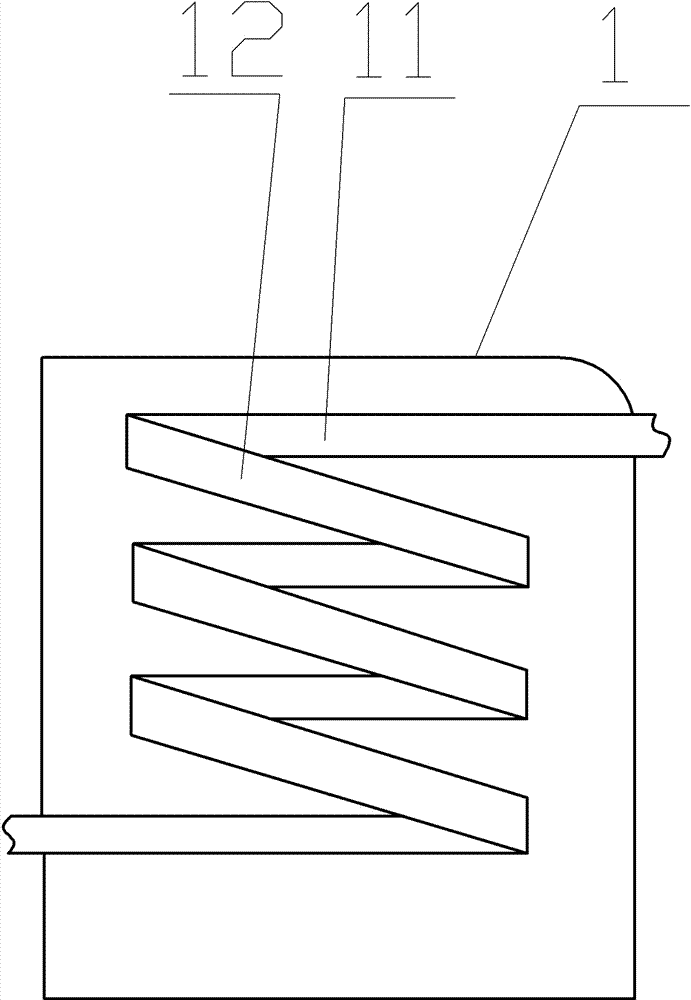

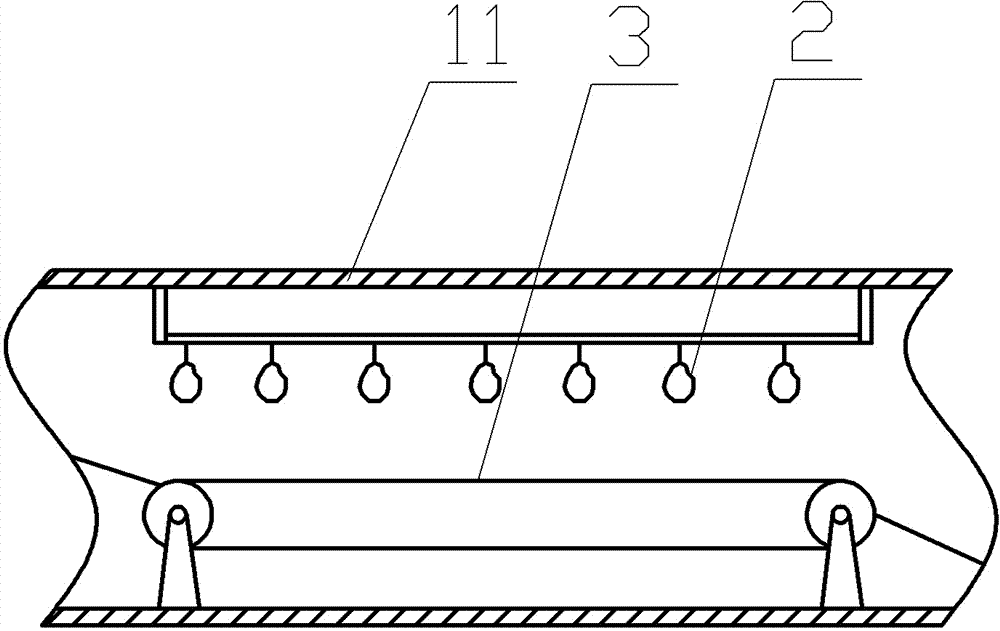

[0014] The reference signs in the accompanying drawings of the description include: housing 1 , heating resistance wire 2 , conveyor belt 3 , horizontal pipe 11 , and spiral pipe 12 .

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: a drying device, including a shell 1, the upper end of the shell is provided with a feeding port, the lower end of the shell is provided with a discharge port, and four horizontal pipes 11 and three spiral pipes 12 are fixed in the shell, and the horizontal pipes are arranged horizontally In the shell, the two horizontal pipes are connected through spiral pipes, the horizontal pipe is connected to the feed port, and the horizontal pipe is connected to the discharge port. It is connected by bolts, which is convenient for installation and disassembly. There are seven radiation heat sources arranged on the fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com