Wire cutting clamp capable of fast clamping

A wire cutting and clamping technology, used in attachments, manufacturing tools, electric processing equipment, etc., can solve the problems of cumbersome operation, consuming more time, affecting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

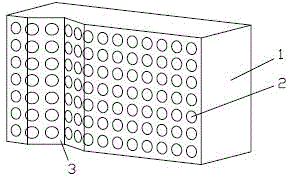

[0011] figure 1 Shown is the wire cutting fixture for fast clamping provided by the present invention, including a suction cup 1, which is a cuboid, one surface of the suction cup 1 is an adsorption surface, and there are multiple rows of round holes 2 on the adsorption surface, and the round holes 2 are filled with magnetic Object; V-shaped groove 3 is opened on the suction surface of the suction cup 1.

[0012] The circular holes 2 are arranged at equal intervals, which is beneficial to make the adsorption force on the workpiece more uniform. The V-shaped groove 3 is located at the end of the sucker 1, and is used for clamping rod-shaped workpieces. V-shaped grooves 3 of different sizes can also be provided in different places according to needs, and the plane part of the adsorption surface is used for clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com