Surface temperature detection device for stirring friction welding leader region

A surface temperature and friction stir technology, which is applied in the direction of measuring devices, thermometers, welding equipment, etc., can solve the problems of lack of dynamic detection of friction stir welding zone, difficulty in measuring the temperature of stirring zone, and difficult detection of dynamic temperature change in welding zone, etc., to achieve structural Simplicity, strong practicality, and high device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

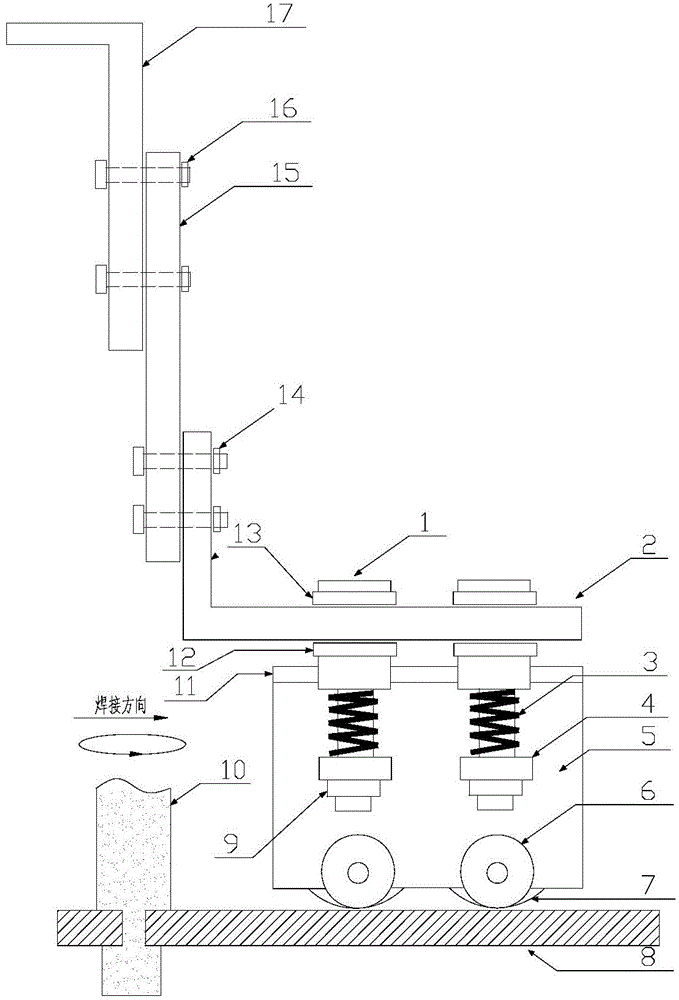

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

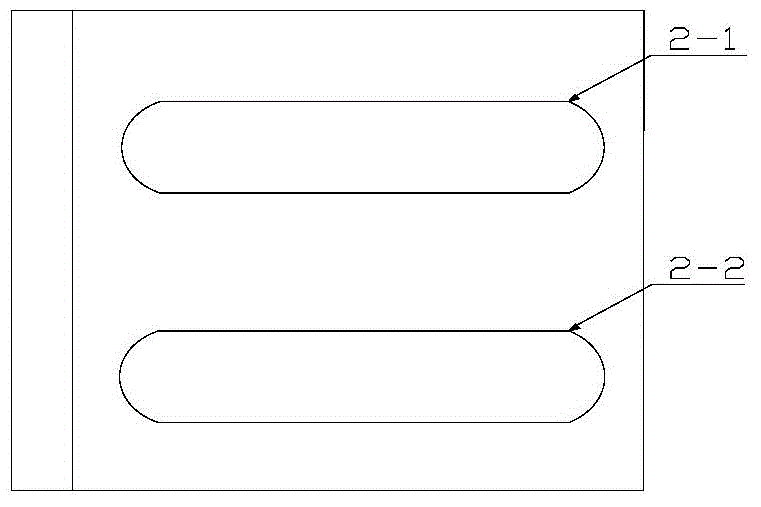

[0029] like Figure 1 to Figure 8 As shown, a friction stir welding leading zone surface temperature detection device of the present invention includes a compression spring thermocouple 7 for detecting the surface temperature of the leading zone, a trolley 5 that drives the compression spring thermocouple 7 to move, and an adjustment device connected to the trolley 5 device, the compression spring thermocouple 7 is connected to the trolley 5 through four sets of thermocouple kits, the side of the trolley 5 is provided with four trolley bosses 4, the trolley boss 4 is connected to the adjustment device through a spring adjustment structure, and the bottom of the trolley 5 is equipped with rollers 6.

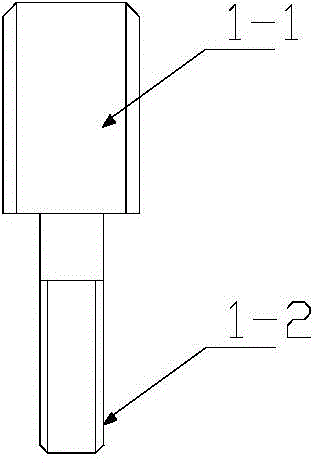

[0030] In the present invention, the thermocouple kit includes a hollow step-shaped thermocouple mounting rod 18-4, a buffer spring 18-3, a pressure sensor 18-2 and a cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com