Bridge abutment knocking-off structure

A bridge abutment and structure technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as increasing project cost, affecting landscape effect and driving smoothness, and achieving the effect of saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

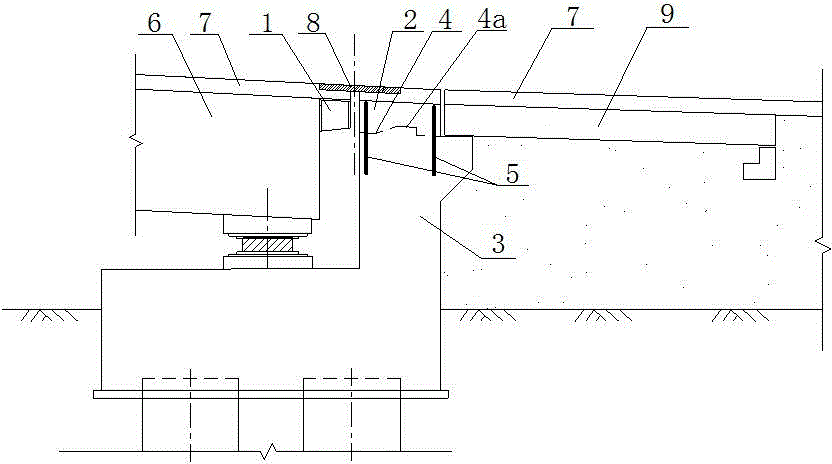

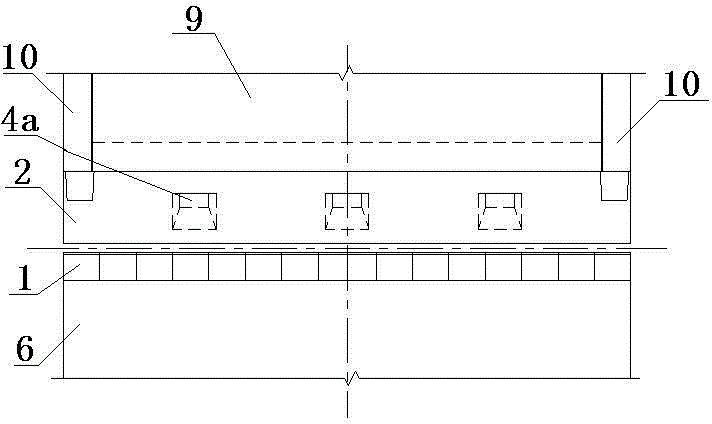

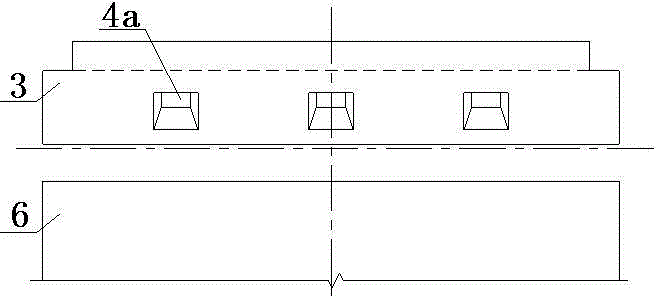

[0022] Embodiment: This embodiment specifically relates to an abutment knock-down structure, the purpose of which is to avoid the installation of super-large telescopic devices in the large gap between the bridge girder body and the abutment parapet, so as to save engineering costs; Under the earthquake, the functional and safety requirements of the ordinary type telescopic device and the abutment; at the same time, it meets the safety requirements of the abutment under the rare earthquake.

[0023] Such as Figure 1-3 As shown, the abutment crash structure includes the bridge girder body 6 and the abutment abutment body 3, and the two are separated by a certain distance. The length is slightly smaller than the distance between the end face of the bridge girder body 6 and the breast wall of the abutment body 3, the bottom surface of the beam end corbel 1 is flush with the top surface of the abutment body 3, and the beam end corbel 1 can be made of steel structure or Reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com