Fatigue test device and method of sliding column assembly

A fatigue test and assembly technology, which is used in measuring devices, vehicle testing, and mechanical component testing. It can solve problems such as errors and difficulty in ensuring test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

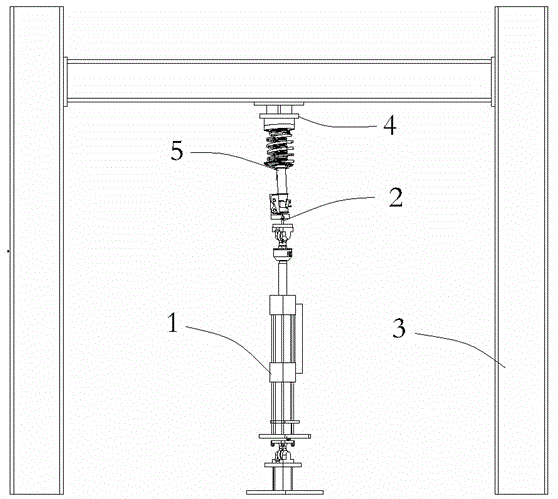

[0020] As shown in the figure, the fatigue test device of the sliding column assembly in this embodiment is composed of a hydraulic servo device 1, an L-shaped clamp 2, a bracket 3, and a main clamp 4. The bracket 3 has two vertical vertical rods and an end The main clamp 4 is fixed on the cross bar connected to the vertical bar; the hydraulic servo device 1 is located below the main clamp 4 , and the bottom end of one end of the L-shaped clamp 2 is connected with the hydraulic servo device 1 .

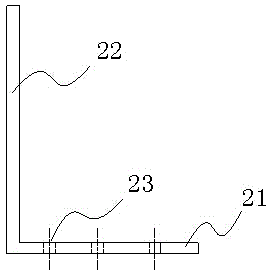

[0021] Among them, such as figure 2 As shown, the L-shaped clamp 2 includes a horizontal plate 21 and a vertical plate 22 that are perpendicular to each other. The angle formed by the horizontal plate 21 and the vertical plate 22 simulates the angle of the sliding column assembly in the actual vehicle state. The axis of the plate 21 is provided with a plurality of bolt holes 23 , the L-shaped fixture 2 is connected with a joint bearing through bolts passing through the bolt holes 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com