Calibration device and calibration method for mems micro force-torque sensor

A technology of torque sensor and calibration device, applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, instrument, etc., can solve the problems of complex calibration process, poor accuracy, inconvenient operation, etc., and achieve accurate measurement results , The loading process is stable and accurate, and the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

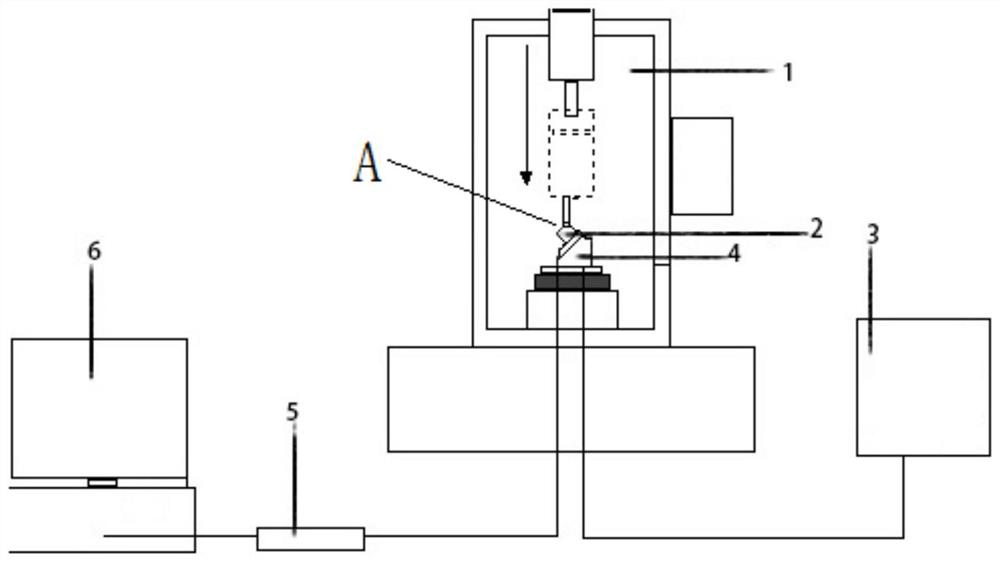

[0034] A kind of calibration device of MEMS micro force-moment sensor, such as figure 1 As shown, it includes a test platform, a nano-indenter 1 located on the test platform, an inclined platform assembly located on the placement platform of the nano-indenter 1, and an analog-to-digital conversion connected with the MEMS micro force-torque sensor 2 to be tested The circuit 5 and the sensor power supply 3 are connected to a computer 6 in order to display data.

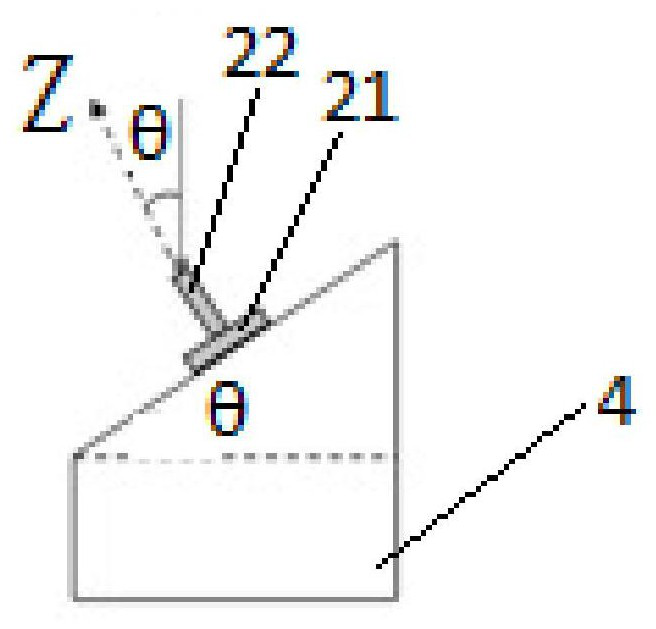

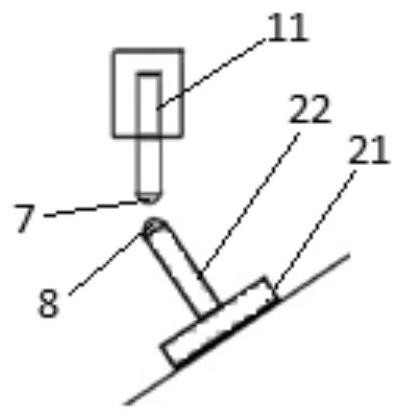

[0035]The MEMS micro force-torque sensor 2 to be tested is a six-axis sensor, including a sensor body 21 and a column 22 connected to the sensor body 21; the sensor body 21 is fixed on the slope of the inclined platform element 4; the force rod 11 of the nanoindentation instrument 1 Align with the column 22 in the vertical direction. The MEMS micro force-torque sensor 2 to be tested consists of its PCB, substrate, cover, leads, sensor, column, and silicone shell. Adhere the sensing chip to the plastic substrate. Epox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com