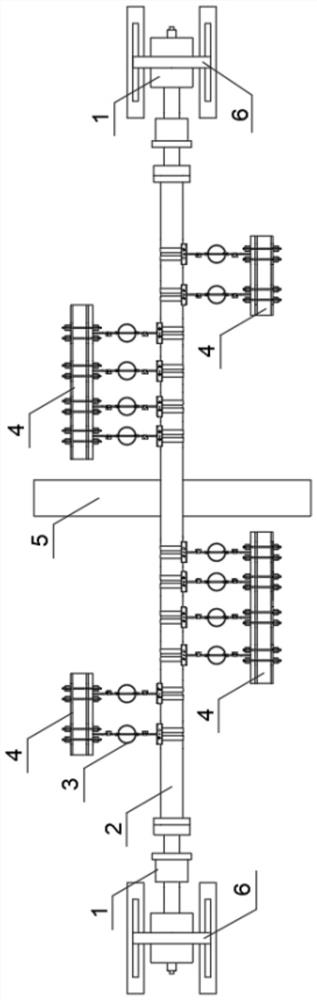

Test device for simulating pipeline crossing strike-slip fault and determination method

A test device and strike-slip fault technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that it is difficult to meet similar conditions, full-scale tests, and inability to carry out raw materials, etc., to meet the theoretical basis, The effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to one embodiment of the present invention, the pressure-bearing part is a metal part, preferably a steel pipe.

[0051] Due to the compressive properties of steel, combined with the existing calculation and simulation means, the following embodiments of the present invention are illustrated by taking the pressure-bearing part as a steel ring.

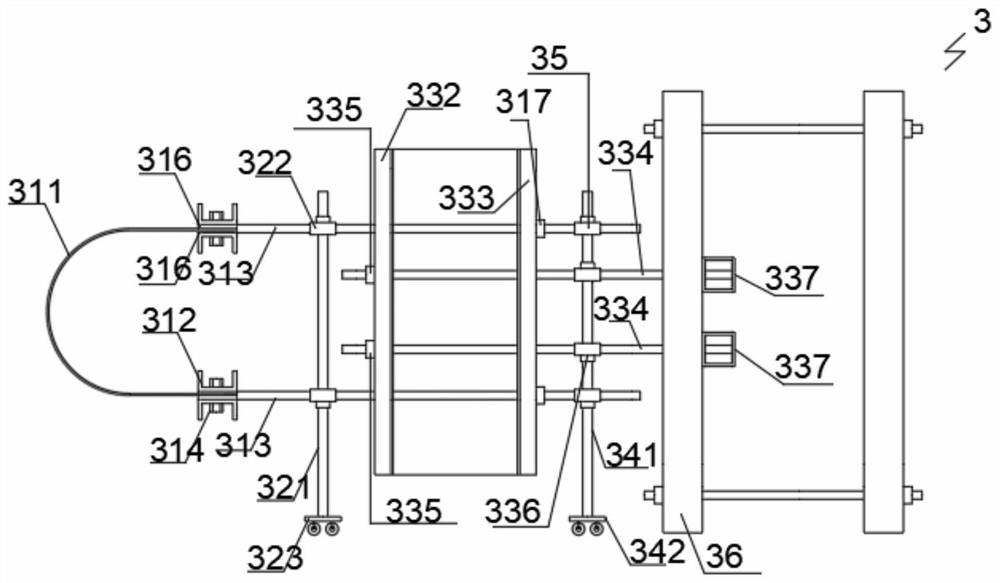

[0052] According to one embodiment of the present invention, as Figure 3a , 3b As shown, the first end of the pressure-bearing structure 3 includes a flexible belt 311, which is connected to the outer peripheral wall of the pipeline in a coiled form. Preferably, the flexible belt is an elastic steel belt. In the figure, the flexible belt is wound around the outer peripheral wall of the pipeline 2 in a semi-enclosed manner.

[0053] According to one embodiment of the present invention, the first end of the pressure-bearing structure 3 also includes a second uniformly distributed load beam 333, which is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com