Design method of shield machine box culvert crane beam structure based on ansys node coupling

A beam structure and box culvert technology, applied in design optimization/simulation, calculation, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

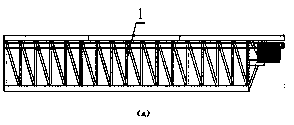

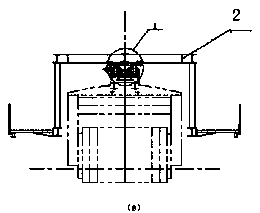

[0020] As shown in Figure 1, the box culvert crane beam 1 is composed of a truss beam 2 and a track beam 3, which are connected together by bolts and pressure plates, and the box culvert crane moves on the track beam 3 when it is working;

[0021] The invention provides a method for designing a shield machine box culvert crane beam structure based on ANSYS node coupling, comprising the following steps:

[0022] (1) Use the beam element BEAM188 in the finite element software ANSYS to establish a geometric model for the box culvert crane beam, and assign each beam with its own section parameters and materials;

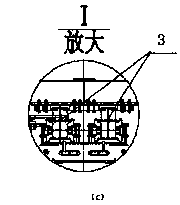

[0023] (2) After the geometric model is established, the geometric model is discretized into a finite element model through the mesh division function of ANSYS, such as figure 2 As shown, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com