Corn husker

A peeling machine and corn technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of broken seeds, grain drop, low peeling efficiency, etc., and achieve the effect of long service life and high peeling rate

Inactive Publication Date: 2015-02-04

何年宝

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current production of corn peeling machine products still has certain deficiencies in terms of technical level. The peeling roller on the peeling machine adopts a single rubber roller or cast iron roller, which has low abrasion resistance, slow conveying, and low peeling efficiency. broken seeds

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

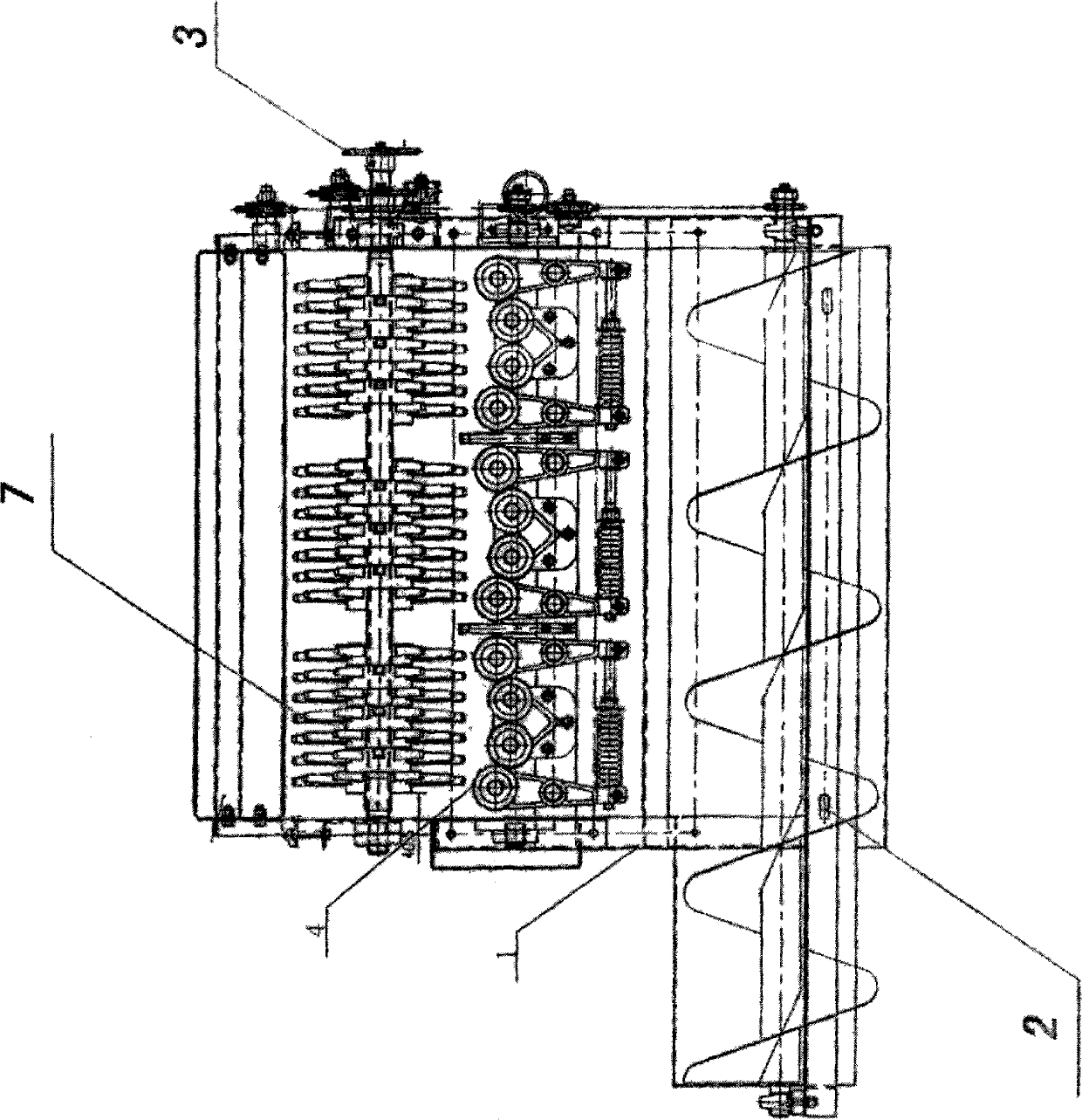

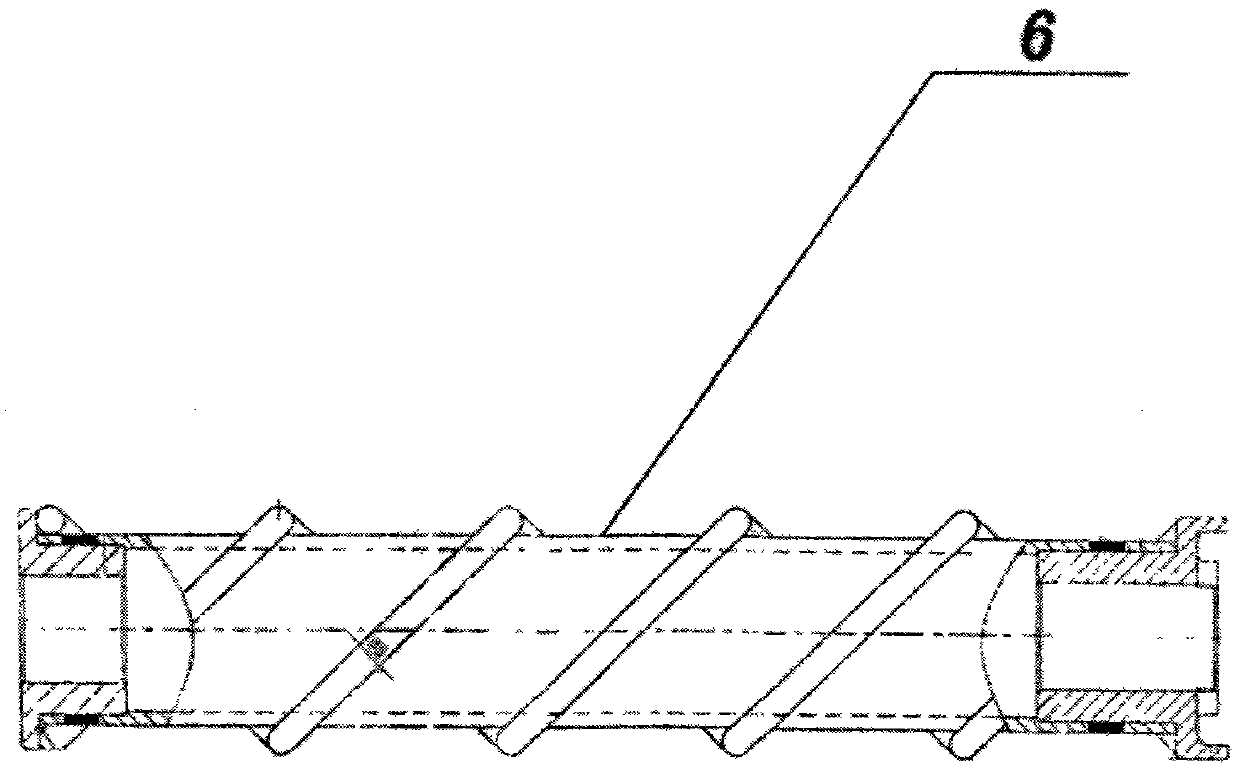

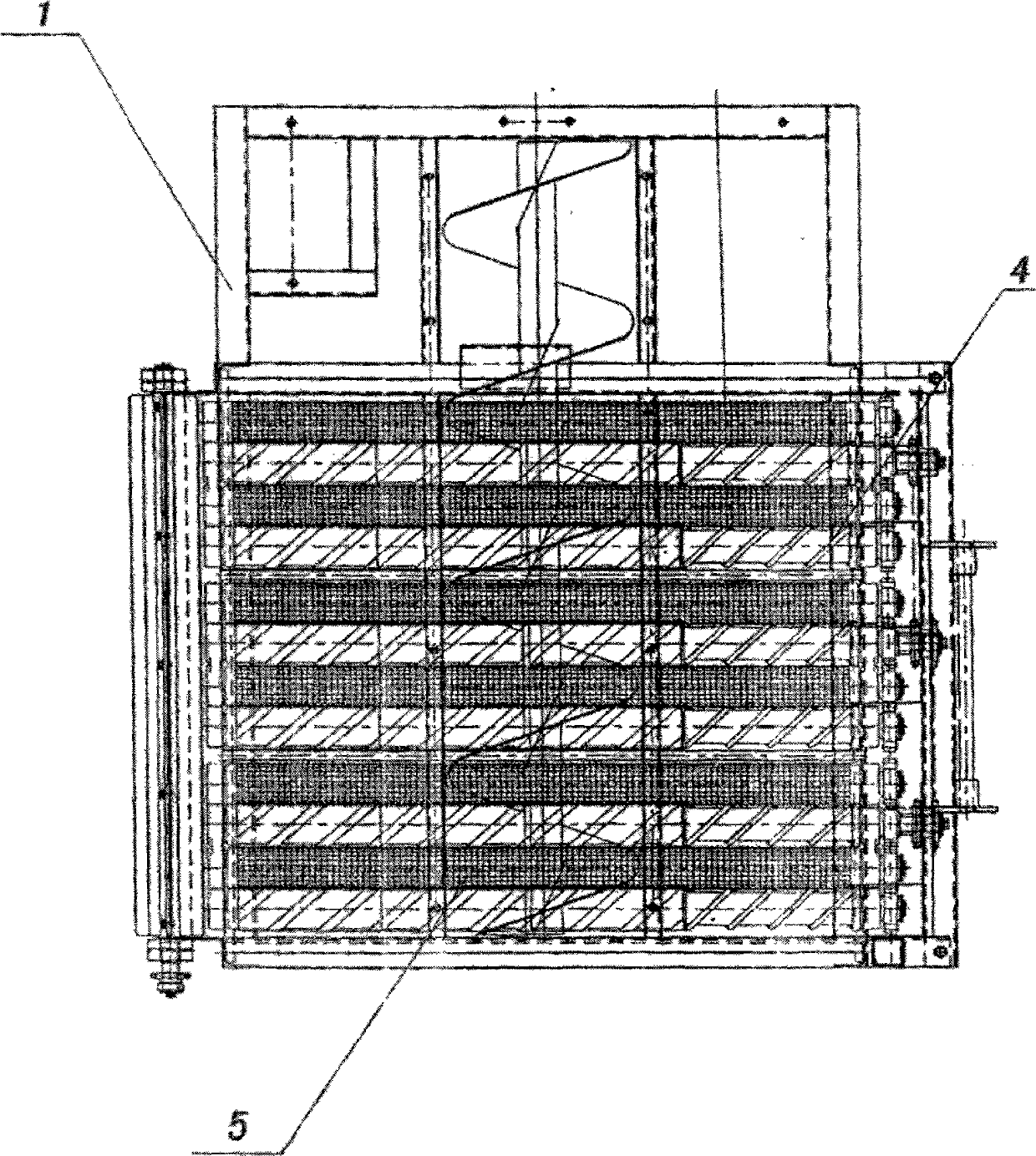

The invention relates to a corn husker which consists of a husker frame, a connecting frame, a chain wheel, husking rolls, rubber rolls, bifilar helix iron rolls and a compression transfer wheel. According to the corn husker, the husking rolls consisting of the rubber rolls and the bifilar helix iron rolls are adopted, wherein the first group consists of the bifilar helix iron rolls, the other groups consist of the rubber rolls, a single thread is casted on each rubber roll, and corn cobs move backwards in the husking process. The bifilar helix iron rolls are large in space, can run relative to the rubber rolls and can be used for rapidly shunting and conveying the corn cobs dropping from a lift conveyer; the wear resistance of rubber is superior to that of cast iron, so that the corn husker is long in service life and high in husking rate; the rubber rolls are not provided with horseshoe nails, so that corn grains can be reduced in the husking process of the corn cobs and seeds can be prevented from breaking. In addition, the compression transfer wheel is a multi-finger compression transfer wheel, the corn cobs are always positioned on the compression transfer wheel from front to back, the helix iron rolls and the rubber rolls, and therefore the husking rate can be greatly increased.

Description

Technical field: The invention relates to an agricultural machine, in particular to a corn peeling machine. Background technique: At present, with the country's strong support for agriculture, as far as the development of my country's crop harvesting machinery is concerned, the general trend is rapid development. However, the current production of corn peeling machine products still has certain deficiencies in terms of technical level. The peeling roller on the peeling machine adopts a single rubber roller or cast iron roller, which has low abrasion resistance, slow conveying, and low peeling efficiency. Broken seeds, dropped grains. Invention content: The purpose of the present invention is to overcome the above shortcomings and provide a corn peeling machine with long service life, high peeling rate and no broken seeds. Technical solution: a corn peeling machine, which is composed of a peeling machine frame, a connecting frame, a sprocket, a peeling roller, a rubber ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01F11/06

Inventor 何年宝

Owner 何年宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com