Slide rail mechanism

A technology of slide rail and synchronous mechanism, which is applied in the direction of household appliances, furniture parts, drawers, etc., can solve the problems of left and right shaking, reduce effective space, generate noise, etc., achieve convenient installation, good mute effect, and avoid deflection or swing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

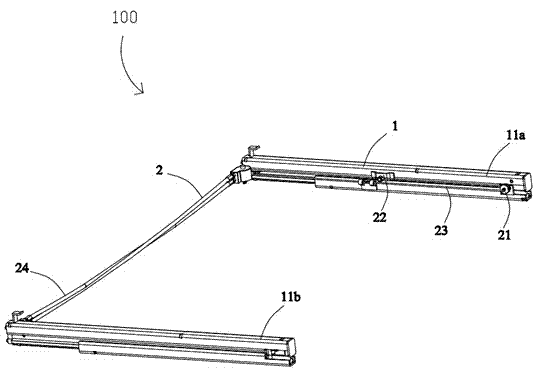

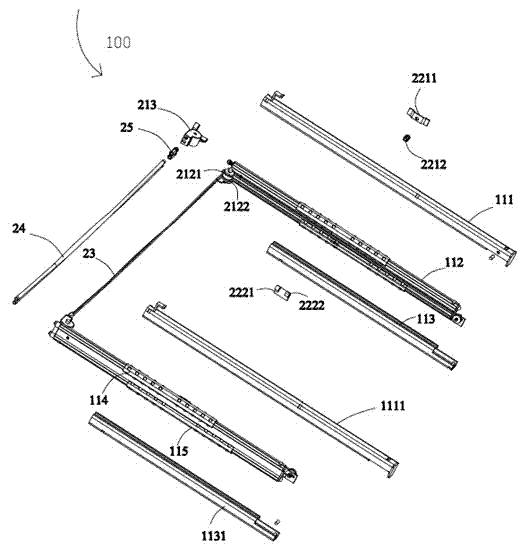

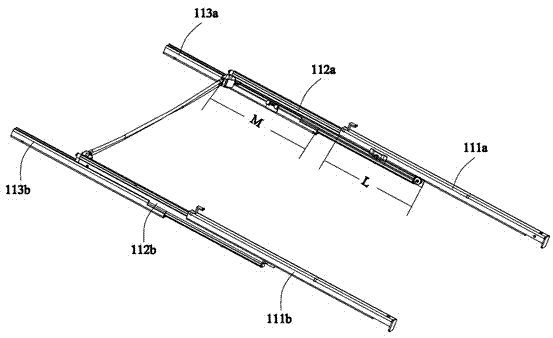

[0021] see Figure 1 to Figure 4 As shown, the present invention provides a slide rail mechanism 100 for pulling out or pushing a drawer (not shown) in a box, including two sets of slide rail assemblies 1 oppositely arranged so that the two sets of slide rail assemblies 1 are kept in sync Mobile synchronization mechanism 2. Of course, the slide rail mechanism 100 can also be used for drawing, expanding or contracting other structures.

[0022] The slide rail assembly 1 includes a first slide rail assembly 11a and a second slide rail assembly 11b, each slide rail assembly 1 has an upper rail 111, a middle rail 112 and a lower rail 113 that are slidably fitted with each other, that is, the first slide rail assembly 11a has a first upper rail 111a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com