Dual-use mold for drawing and flanging

A mold and flanging technology, which is applied in the field of cold stamping molds, can solve the problems of high trial production costs and increased prototype development costs, and achieve the effects of saving trial production costs, shortening mold change time, and reducing casting pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

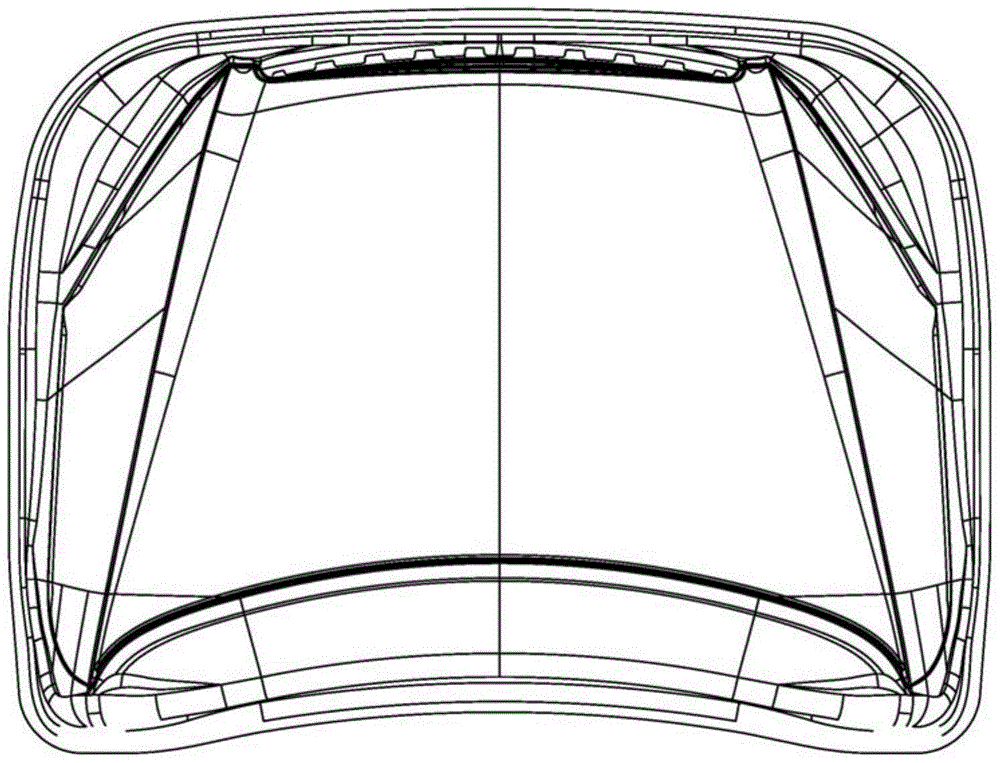

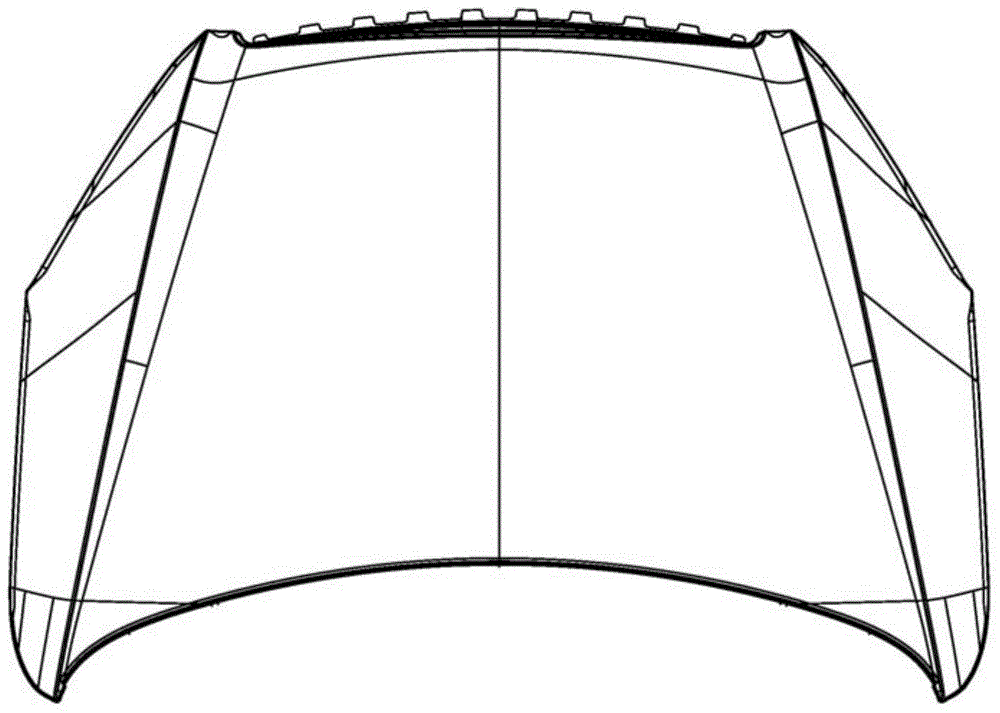

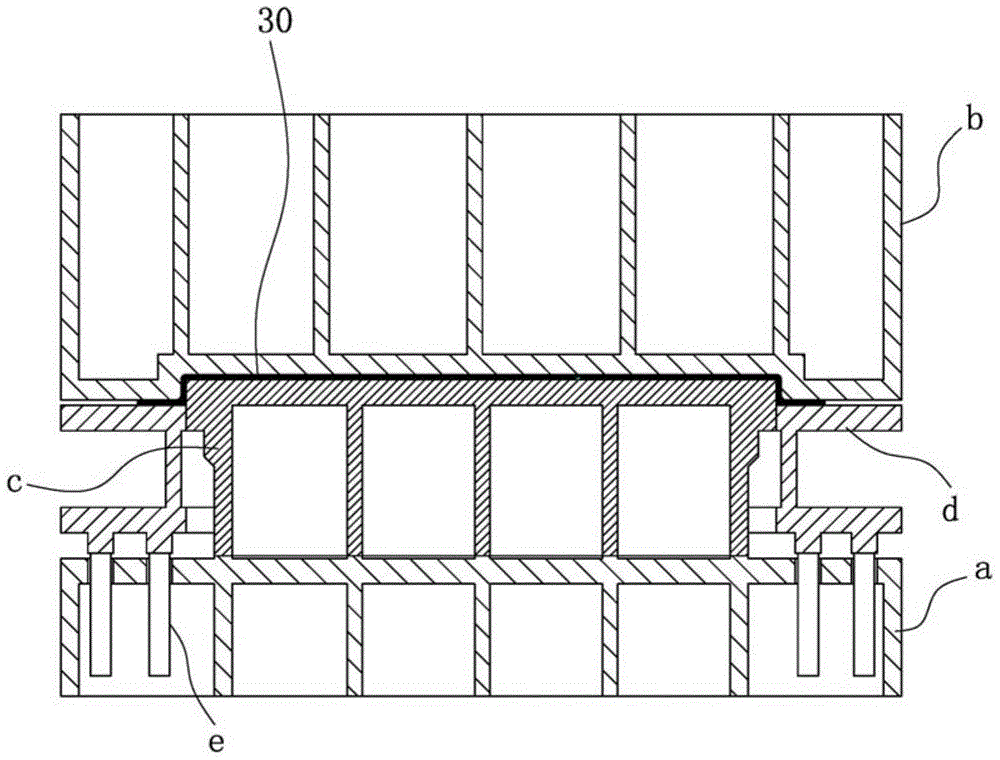

[0020] Such as Figure 5 , 6 , 7, and 8, a dual-purpose mold for drawing and flanging includes a punch 11 and a die 20 that are opened and closed with each other, and at least one of the punch 11 and the die 20 is driven by a drive unit. The reciprocating motion is used to realize the opening and closing action. The cavity of the die 20 is stepped and the large end of the cavity faces downward. The edge of the punch 20 is provided with a detachable insert 111. When the When the insert 111 is mounted on the punch 11, the size of the punch 11 is adapted to the size of the large end of the cavity. When the insert 111 is removed, the size of the punch 11 is adapted to the size of the small end of the cavity. The periphery of the punch 11 is also provided with a first clamping plate 12 for cooperating with the end face of the die 20 to clamp the sheet material 30 to be processed. The direction is parallel to the mold opening direction, and the bottom of the first clamping plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com