Square wood fixed-length cutting equipment tooling and cutting process

A technology of cutting equipment and cutting technology, which is applied in the direction of sawing equipment, wood processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency of square wood, achieve the effect of removing potential safety hazards and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

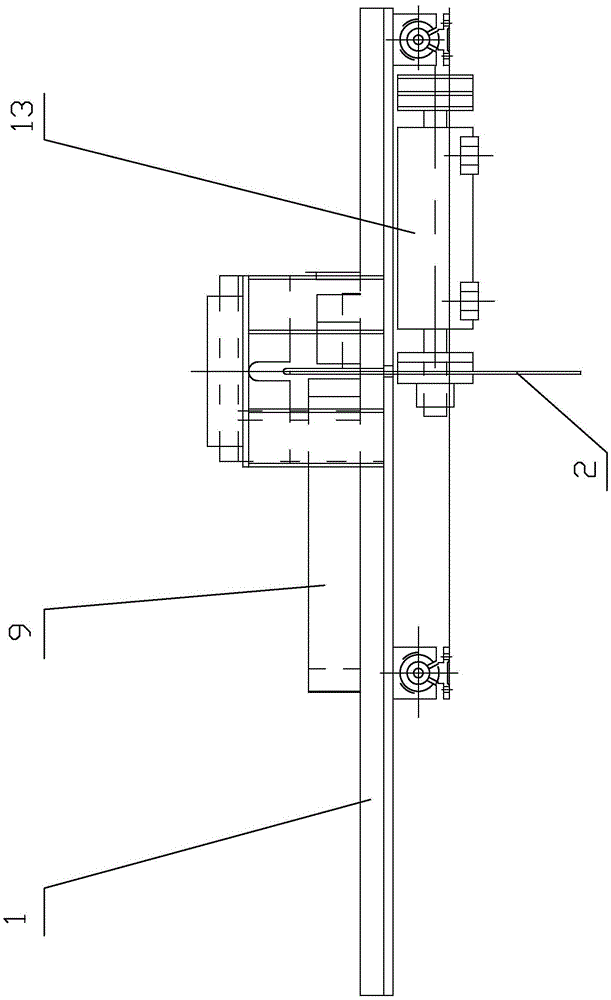

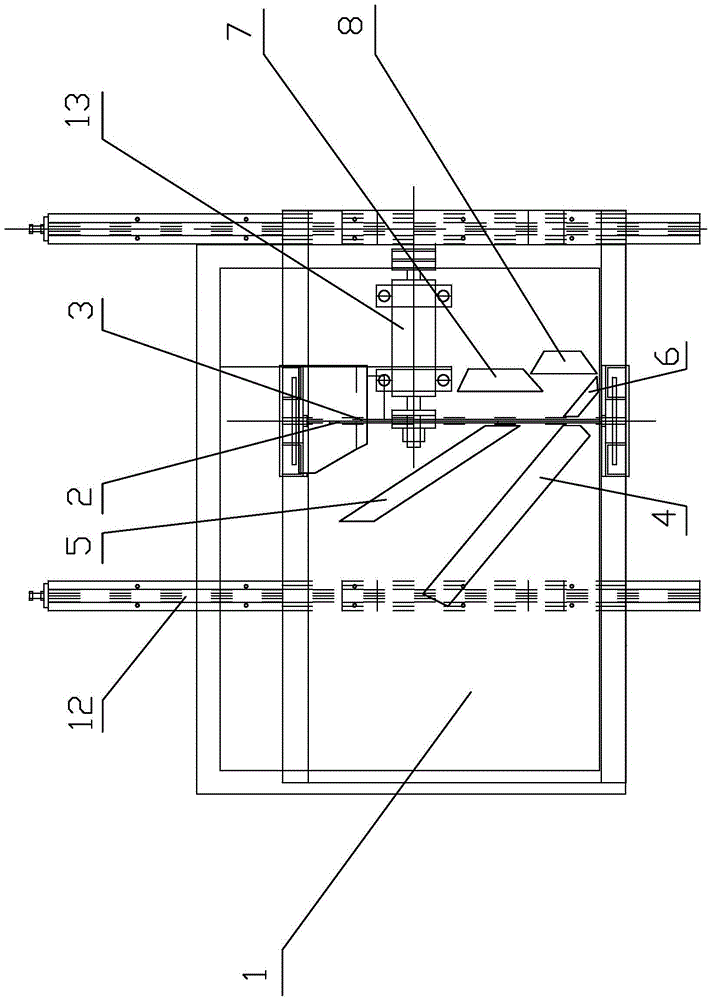

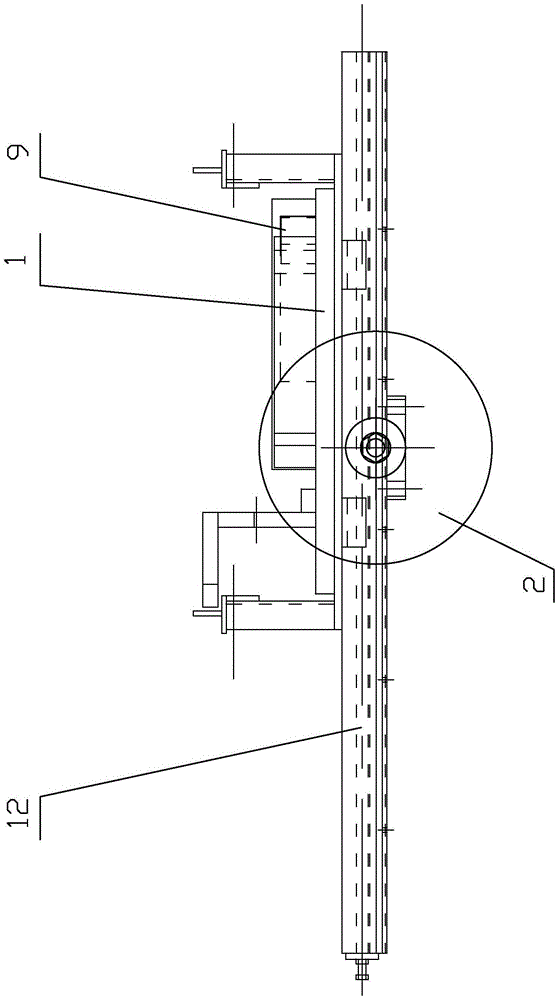

[0027] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0028] The tooling of the square wood fixed-length cutting equipment of the present invention includes equipment and tooling. The equipment includes a workbench 1 and a disc saw 2. The workbench 1 is installed on the frame through the left and right guide rail mechanisms 12 in the front and rear directions, and The reciprocating linear motion in the forward and backward direction is realized by the transmission mechanism, and the forward and backward knife grooves 3 are provided on the worktable 1 along the linear motion direction, and the motor 13 is arranged in the frame below the workbench 1. 2. Installed vertically on the horizontal output shaft of the motor 13 and placed in the knife slot 3, the advancement of the workbench 1 is the feed cutting of the disc saw 2, and the retreat of the workbench 1 is the retreat ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap