Grey board splicing machine

A technology for a plastering machine and a sealing board, applied in the field of machinery, can solve the problems of low degree of automation and low production efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

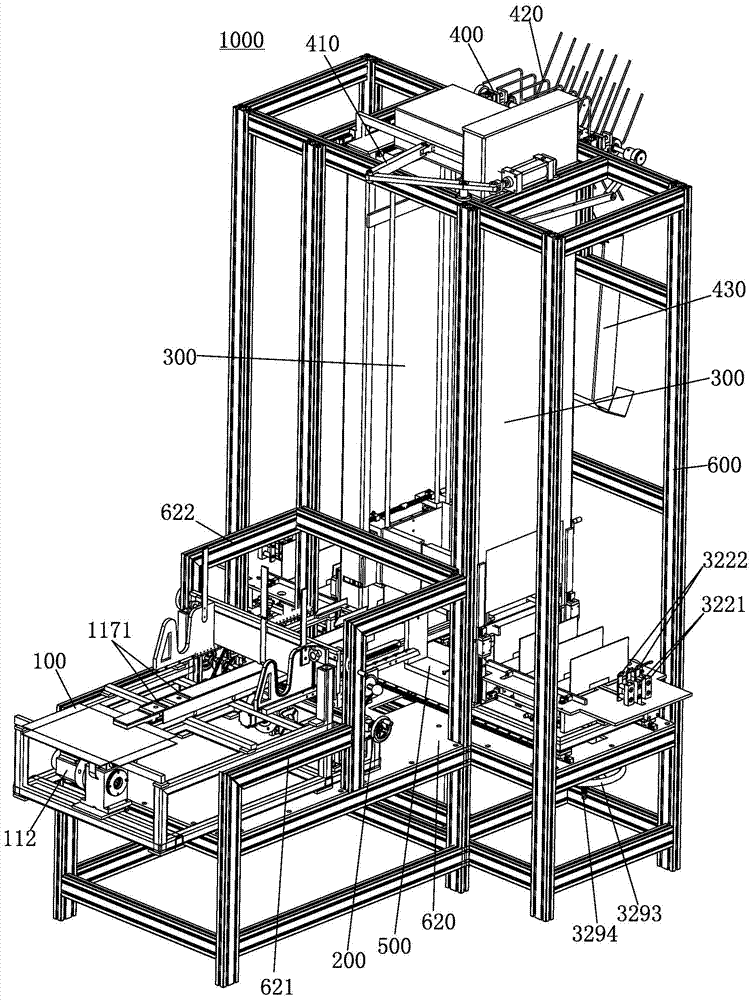

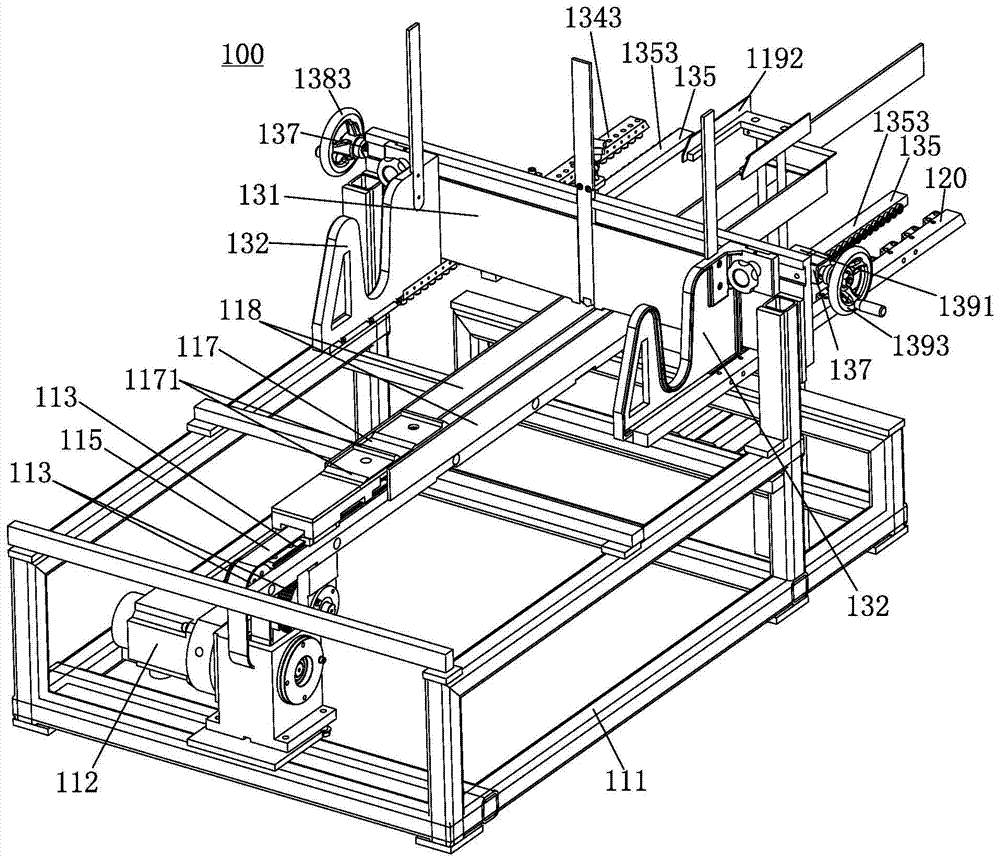

[0024] refer to Figure 1 to Figure 14 , The gray board machine 1000 of the present invention includes a gift box automatic forming frame 600, a three-piece conveying device 100, a gluing mechanism 200, a side-feeding device 300 for two sealing plates, an ejecting mechanism 500 and a box-connecting device 400.

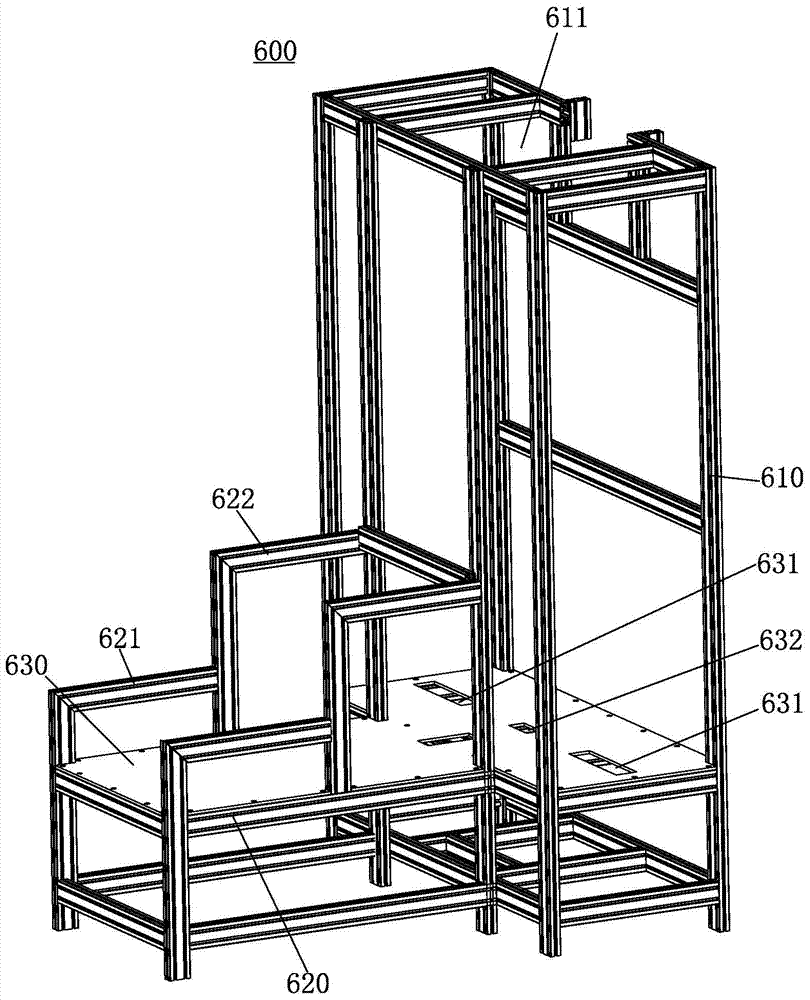

[0025] The gift box automatic forming frame 600 includes a sealing board side-feeding mechanism support 610 , a three-piece conveying mechanism support 620 and a support plate 630 .

[0026]The three-piece conveying mechanism bracket 620 is connected to the middle part of the lower front end of the sealing plate side-entry mechanism bracket 610 , and the three-piece conveying mechanism bracket 620 includes a first step bracket 621 and a second step bracket 622 . The support plate 630 is fixed horizontally on the support 610 of the sealing plate side-entry mechanism and the support 620 of the three-piece conveying mechanism. The support plate 630 is located below the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap