A kind of production method of preparing dipotassium phosphate byproduct plum tree special fertilizer

A dipotassium phosphate and production method technology, applied in the direction of chemical instruments and methods, applications, phosphorus compounds, etc., can solve the problems of low purity of dipotassium phosphate and unusable active ingredients in the filtrate, so as to achieve good absorption rate and ensure supply , Good effect of controllable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

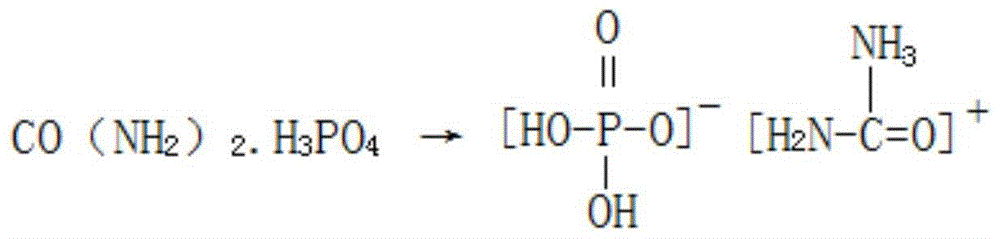

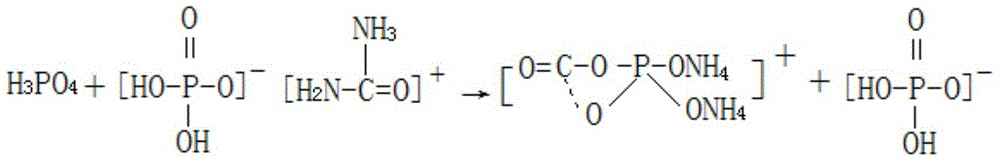

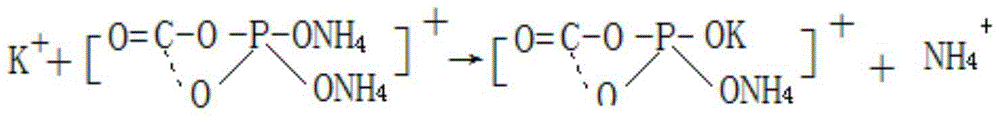

Method used

Image

Examples

Embodiment 1

[0057] A kind of production method of preparing dipotassium phosphate by-product plum tree special fertilizer provided by the present embodiment mainly comprises the following steps:

[0058] 1) Mix phosphoric acid and urea at a molar ratio of 1.2:1, raise the temperature from 80°C to 160°C at a heating rate of 6°C / min, stir and react for 4-5 hours, and separate the intermediate; then use the intermediate and hydrogen The potassium oxide solution is mixed according to the molar ratio of 1:1.4, and the pH value is adjusted to 8.5. After the reaction is completed, a slurry containing nitrogen, phosphorus, and potassium is obtained, and the slurry containing nitrogen, phosphorus, and potassium is placed in a cooling crystallizer Cool down to 35-40°C, carry out crystallization and filtration treatment, and circulate the filtrate in the cooling crystallizer for crystallization treatment, the obtained filter cake is a dipotassium phosphate product, and detect the component content in...

Embodiment 2

[0065] A kind of production method of preparing dipotassium phosphate by-product plum tree special fertilizer provided by the present embodiment mainly comprises the following steps:

[0066]1) Mix phosphoric acid and urea at a molar ratio of 1.5:1, raise the temperature from 80°C to 160°C at a heating rate of 6°C / min, stir and react for 4-5 hours, and separate the intermediate; then use the intermediate and hydrogen The potassium oxide solution is mixed according to the molar ratio of 1:1.1, and the pH value is adjusted to 8.5. After the reaction is completed, a slurry containing nitrogen, phosphorus, and potassium is obtained, and the slurry containing nitrogen, phosphorus, and potassium is placed in a cooling crystallizer Cool down to 35-40°C, carry out crystallization and filtration treatment, and circulate the filtrate in the cooling crystallizer for crystallization treatment, the obtained filter cake is a dipotassium phosphate product, and detect the component content in ...

Embodiment 3

[0073] A kind of production method of preparing dipotassium phosphate by-product plum tree special fertilizer provided by the present embodiment mainly comprises the following steps:

[0074] 1) Mix phosphoric acid and urea at a molar ratio of 1.3:1, raise the temperature from 80°C to 160°C at a heating rate of 6°C / min, stir and react for 4-5 hours, and separate the intermediate; then use the intermediate and hydrogen The potassium oxide solution is mixed according to the molar ratio of 1:1.3, and the pH value is adjusted to 8.7. After the reaction is completed, a slurry containing nitrogen, phosphorus, and potassium is obtained, and the slurry containing nitrogen, phosphorus, and potassium is placed in a cooling crystallizer Lower the temperature to 35-40°C in the middle, carry out crystallization and filtration treatment, and circulate the filtrate in the cooling crystallizer for crystallization treatment, the obtained filter cake is dipotassium phosphate product, and detect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com