Pushing and setting device

一种推靠臂、密封堵的技术,应用在井眼/井部件、土方钻采等方向,能够解决探头与地层接触面积小、不能直接提拉仪器、探头不能实现均匀接触井壁等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

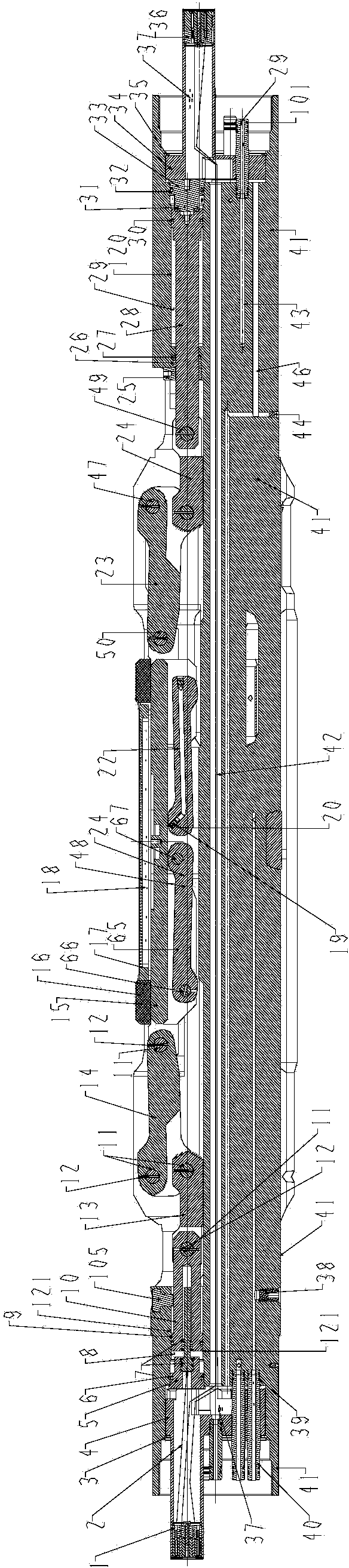

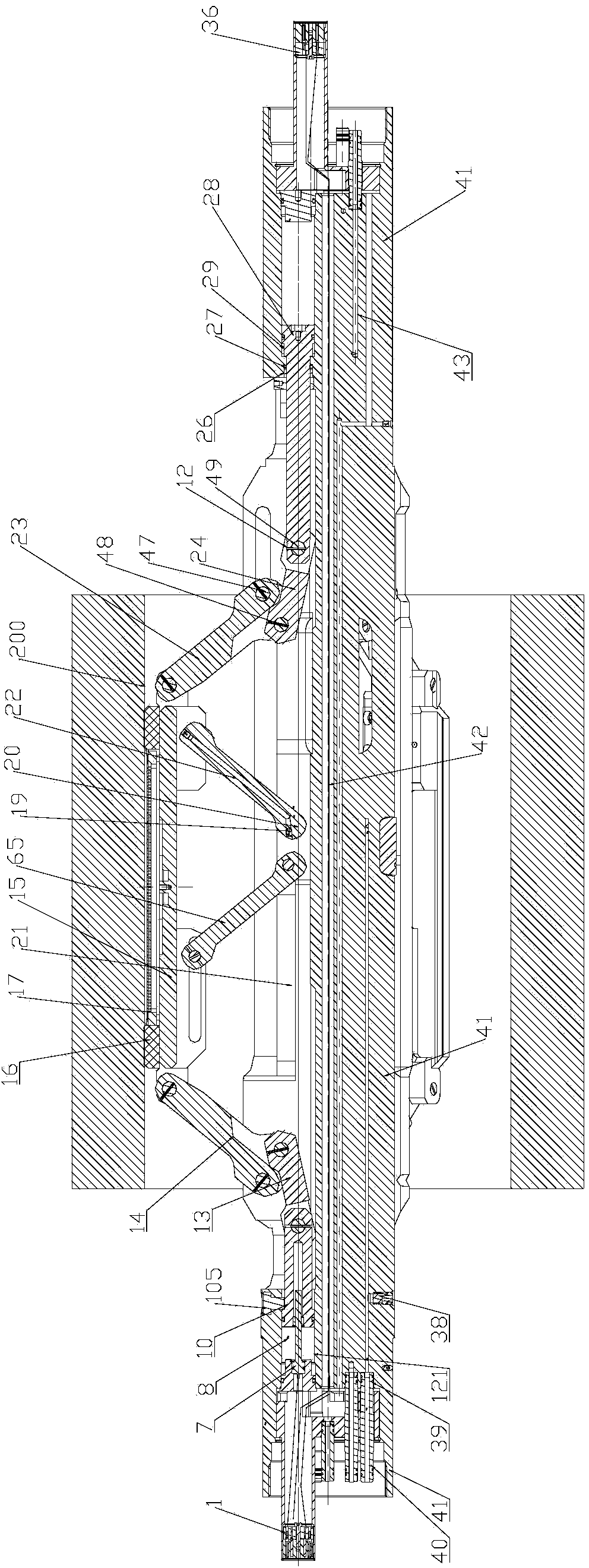

[0026] In order to better understand the purpose and function of the present invention, the structure and working process of a specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] In order to overcome the shortcomings in the prior art, the three-arm seat seal pusher for oil exploration described in this embodiment includes three push-back pistons and fluid passages on the left part, three six-rod structures in the middle and other The inner fluid channel, the three push pistons and the fluid channel on the right part, also includes the upper and lower electrical connection multi-core guide joints.

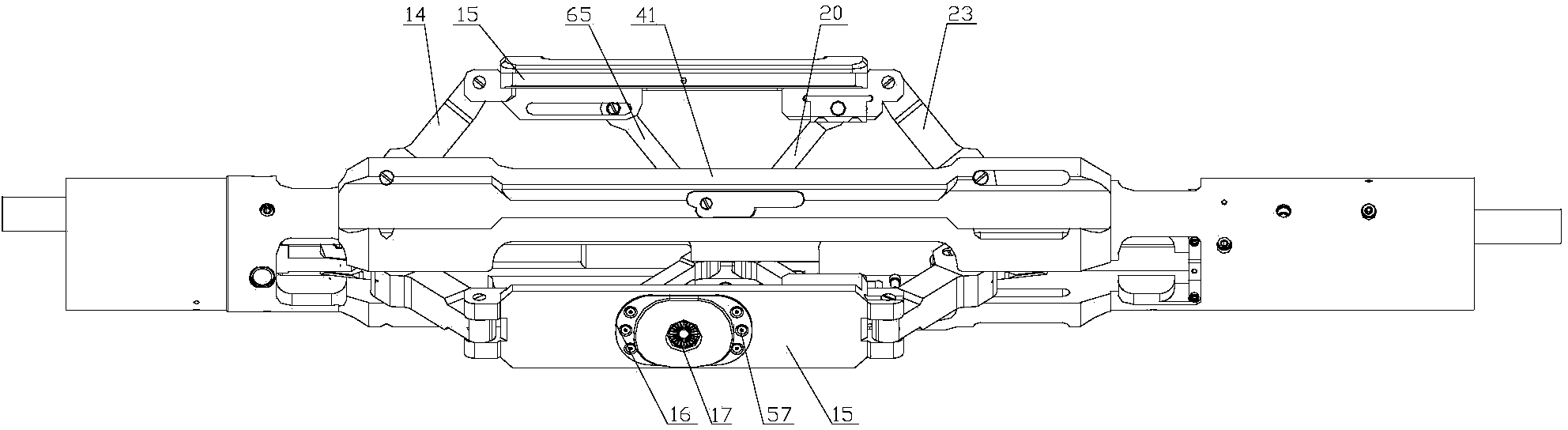

[0028] Such as figure 1 As shown, the pushing and setting device in this embodiment includes three sets of pushing arms uniformly and radially arranged on the main base 41, and the three pushing pistons driven by the hydraulic cylinder respectively move, and the three pushing pistons The three pushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com