Anti-derailment lower chain wheel structure of TH type hoister

A hoist and anti-derailment technology, applied in portable hoisting devices, belts/chains/gears, conveyors, etc., can solve problems such as poor bearing sealing, easy derailment of chains, and easy damage to bearings, and solve bearing damage and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

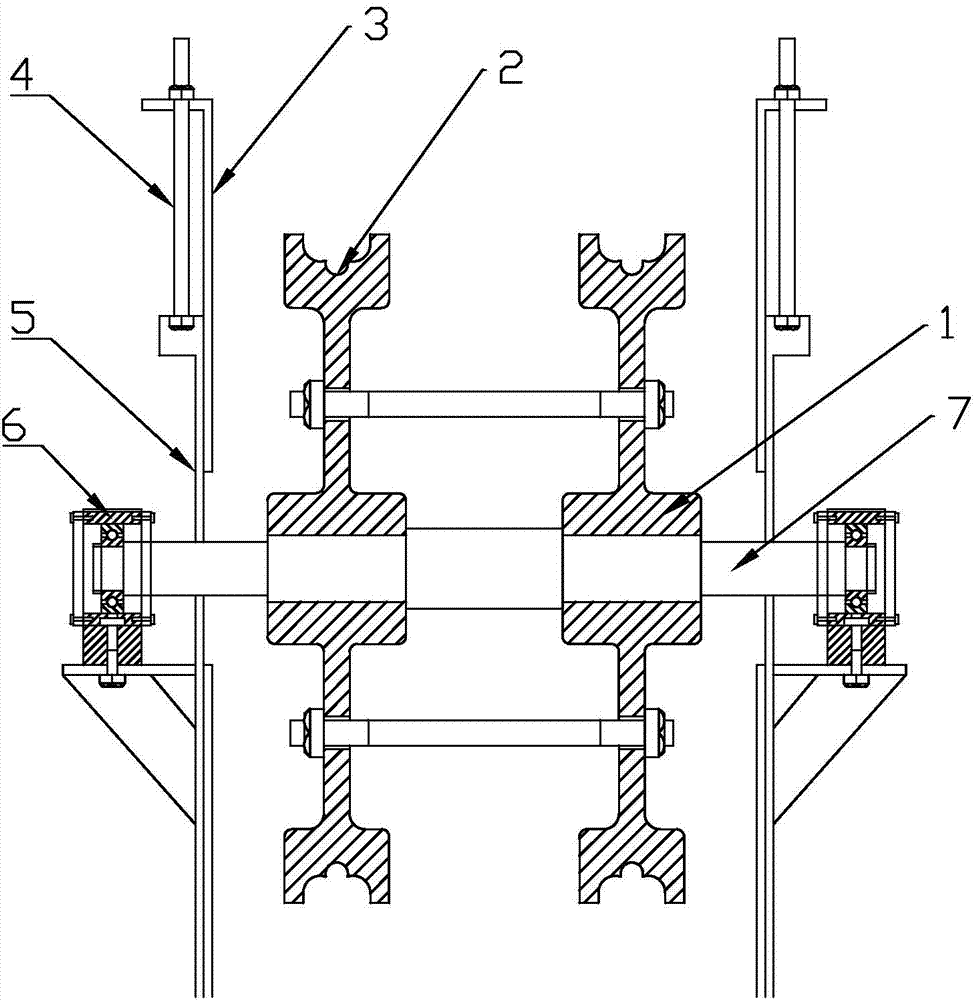

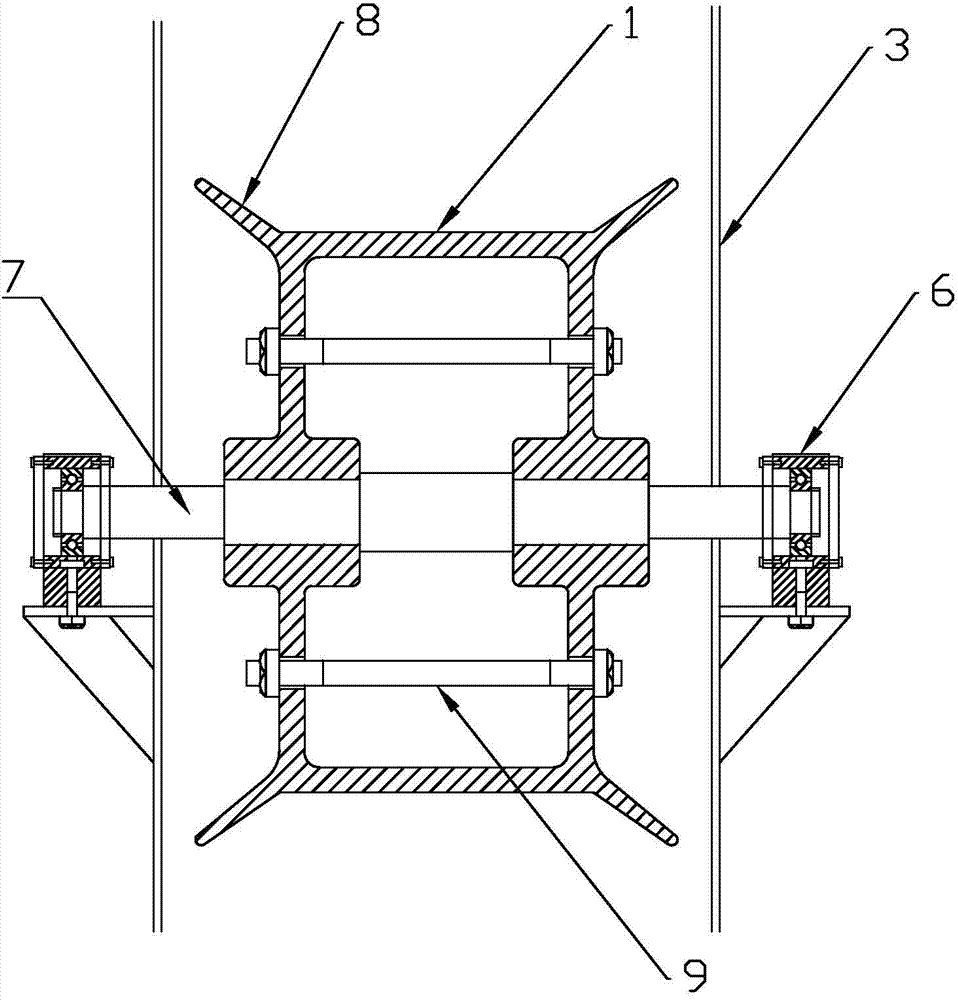

[0015] Such as figure 2 shown. A TH-type hoist anti-derailment lower sprocket structure, including a lower sprocket 1, the lower sprocket 1 is arranged on a sprocket shaft 7, and the two ends of the sprocket shaft 7 protrude from the hoist housing 3 and are installed at the end There are bearings and tile seats 6, the lower sprocket 1 is cylindrical, and the two side edges of the lower sprocket 1 are provided with annular inclined raised edges 8.

[0016] In order to reduce the weight of the lower sprocket 1 and obtain good mechanical properties, a cavity is provided inside the lower sprocket 1 .

[0017] Two bolts 9 are symmetrically distributed on the lower sprocket 1 , and the bolts 9 further enhance the mechanical properties of the lower sprocket 1 .

[0018] The chain of the present invention is located between the protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com