cleaning device

A technology of cleaning device and cleaning rack, which is applied in the direction of cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of affecting the use effect, complicated overall operation, and low work efficiency, so as to achieve good use effect, reduce time consumption and improve work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

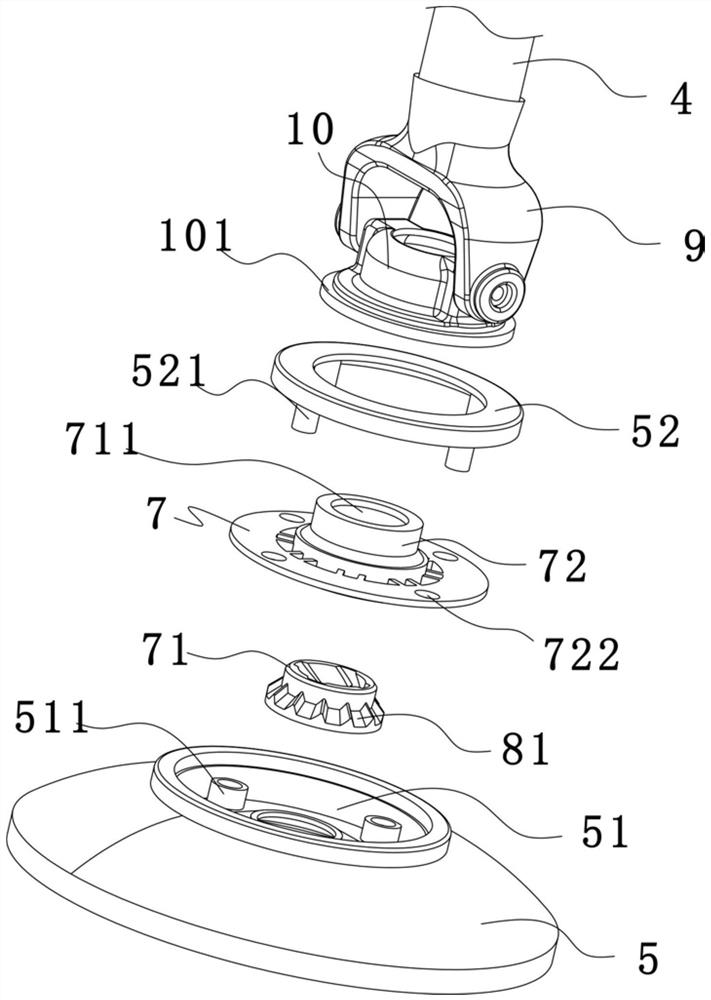

[0074] like Figure 6-10 As shown, the difference between this embodiment and Embodiment 1 is that: a bearing is provided between the connecting piece 72 and the end cover 52; There is a non-rotation matching structure, through which the anti-rotation cooperation between the cleaning basket and the rotating part can be realized, so that when the rotating part rotates, the cleaning basket can be driven to rotate synchronously; through the setting of the anti-rotation matching structure, Realize that the rotating parts can drive the cleaning rack to act together when rotating, and then ensure that the cleaning rack can rotate synchronously with the mop disc, and the dehydration basket will not affect the rotation speed of the mop disc. The mop disc rotates fast and the dehydration effect is good; The anti-rotation matching structure includes a lower anti-rotation piece 30 and an upper anti-rotation piece 40, the lower anti-rotation piece 30 is a tapered convex portion 301 formed...

Embodiment 3

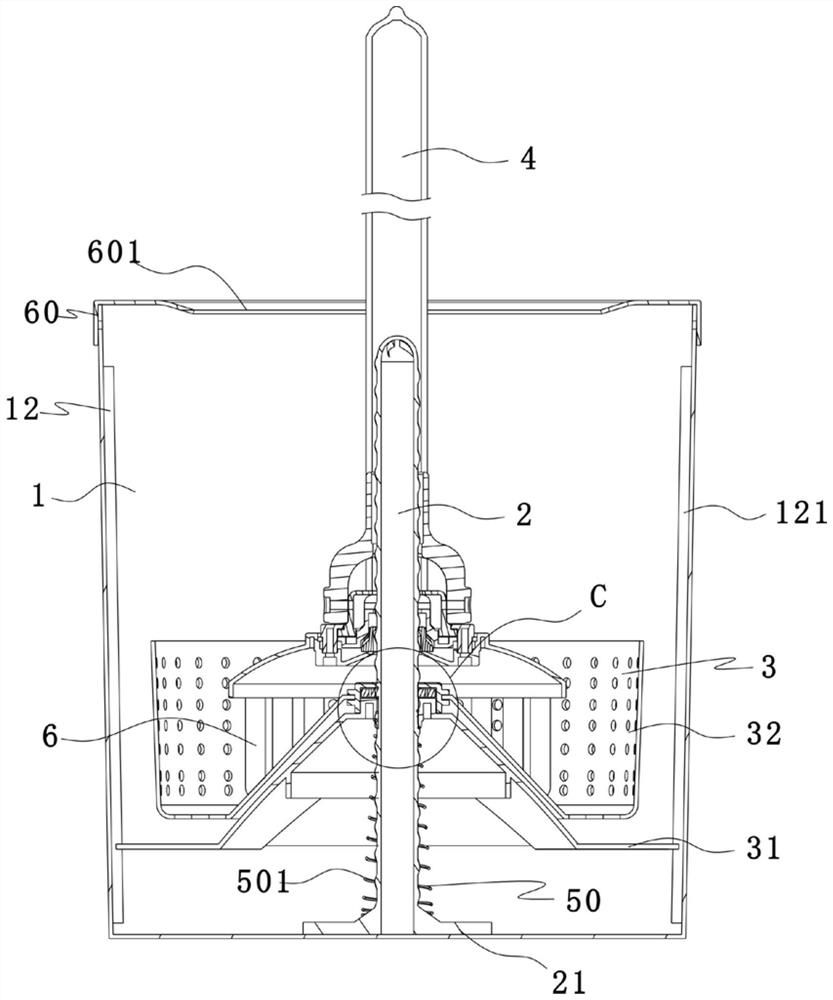

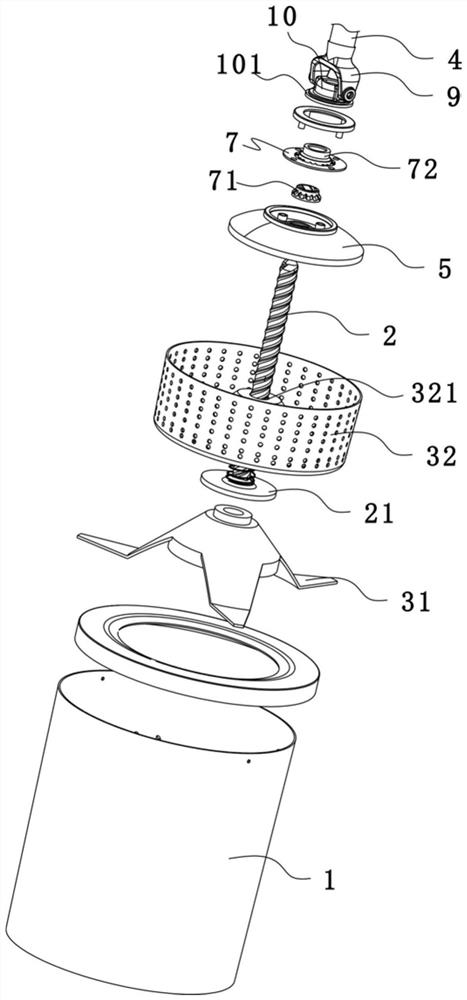

[0078] like Figure 11-17 As shown, a cleaning device includes a mop and a mop barrel matched with the mop. Specifically, the mop includes a rod body 4, a Y-shaped piece 9, a T-shaped joint 10, a mop tray 5, and a mop tray arranged on the mop tray. Mopping, elastic positioning parts and end caps 52, the Y-shaped piece 9 is fixed on the lower part of the rod body 4, the T-shaped joint 10 is hinged with the Y-shaped piece 9, and the T-shaped joint 10 can be generated relative to the mop tray 5 Rotate; the mop bucket includes a barrel body 1, a drive rod 2 located in the barrel body, a cleaning frame 3 located on the drive rod, a driving device and a reset component 50, and the cleaning frame 3 can move up and down along the drive rod 2 and relatively drive The rod 2 rotates; the driving device is used to drive the cleaning rack to rotate in one direction during the downward movement of the cleaning rack 3; the reset component 50 is used to drive the cleaning rack to reset upward...

Embodiment 4

[0089] like Figure 18-25 As shown, a cleaning device includes a mop and a mop bucket matched with the mop. Specifically, the mop bucket includes a bucket body 1, a support rod 2 disposed in the bucket body, and a cleaning frame 3 disposed on the support rod And the reset part 50, the cleaning frame 3 can move up and down along the length direction of the support rod 2, and the reset part 50 is used to drive the cleaning frame upward to reset after the cleaning frame moves down; the support rod 2 is a smooth plastic rod The bottom of the barrel body 1 is arched upwards to form a boss 13, the center of the boss 13 extends downwards to form a cylindrical groove 131, and the support rod is fixedly inserted in the cylindrical groove 131, Thereby realize that support rod is fixedly connected in staving; Described mop comprises rod body 4, Y-shaped piece 9, T-joint 10, mop disc 5, is located on the mopping hair on the mop disc and driving device, specifically, described rod body 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com