cleaning tools

A technology for cleaning tools and cleaning racks, which can be used in cleaning equipment, cleaning machinery, carpet cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

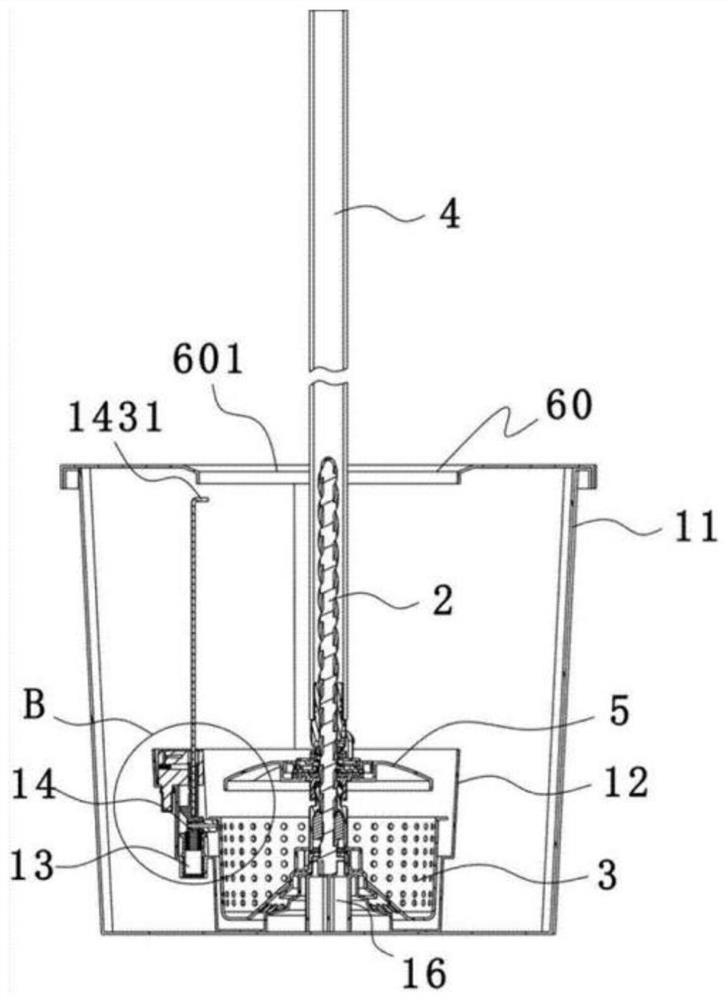

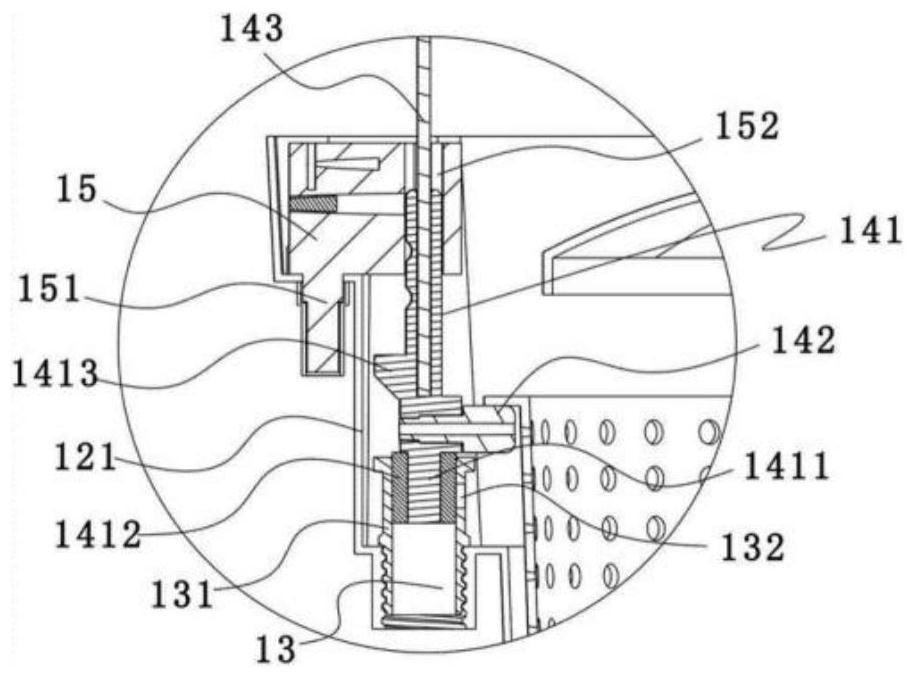

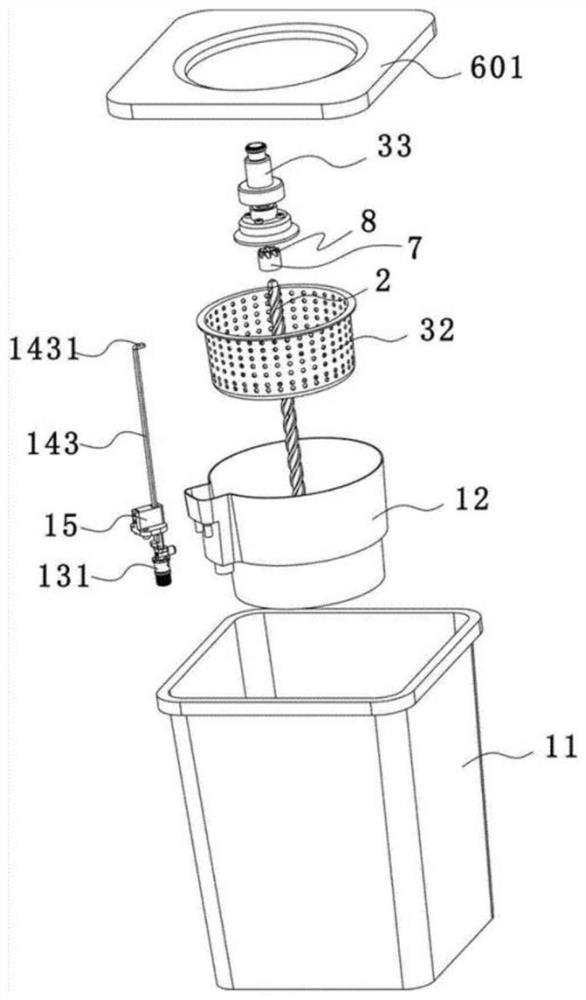

[0070] Such as Figure 1-6 As shown, a cleaning tool includes a mop and a mop bucket matched with the mop. Specifically, the mop bucket includes a bucket body 11, an inner bucket 12 located in the bucket body, a water inlet channel 13, an opening and closing device 14, Drive rod 2, cleaning frame 3 and driving device, the water inlet channel 13 is used to transport the water in the barrel body 11 to the inner barrel, the opening and closing device 14 is used to stop or open the water inlet channel 13, the The mop disc 5 can move up and down along the drive rod 2, and the drive device is used to drive the mop disc 5 to rotate in one direction during the process of pressing down on the rod body; the drive rod 2 is preferably a twist rod made of plastic , the threads on the twist rod 2 can be set to be equidistant, or be set to be dense to sparse, or be set to be sparse to dense, or be set to be dense and alternate, depending on actual usage conditions, without specific limitatio...

Embodiment 2

[0084] Such as Figure 7-11 As shown, a cleaning tool includes a mop and a mop bucket matched with the mop. Specifically, the mop bucket includes a bucket body 11, an inner bucket 12 located in the bucket body, a water inlet channel 13, an opening and closing device 14, Drive rod 2, cleaning rack 3, the water inlet channel 13 is used to transport the water in the barrel body 11 to the inner barrel, the opening and closing device 14 is used to stop or open the water inlet channel 13, and the The driving rod 2 moves up and down; the driving rod 2 is preferably a twist rod made of plastic, and the threads on the twist rod 2 can be set to be equidistant, or can be set from dense to sparse, or from sparse to dense. , or set to alternate density, according to the actual use, not specifically limited; the drive rod 2 includes an outer rod 22 and an inner rod 23 pierced in the outer rod, and the outer rod 22 is made of plastic The inner rod 23 is preferably made of metal; the bottom ...

Embodiment 3

[0097] Such as Figure 12-18 As shown, a cleaning tool that is convenient to use includes a mop and a mop bucket matched with the mop. Specifically, the mop bucket includes a bucket body 11, an inner bucket 12 located in the bucket body, a water inlet channel 13, an opening and closing Device 14, drive rod 2, cleaning frame 3, the water inlet channel 13 is used to transport the water in the barrel body 11 to the inner barrel, the opening and closing device 14 is used to stop or open the water inlet channel 13, the It can move up and down along the drive rod 2; the drive rod 2 is preferably a plastic rod; the bottom of the inner barrel 12 is arched upwards to form a boss 16, and the center of the boss 16 extends downward to form a cylindrical concave groove, and the outer rod 22 is fixedly passed through the cylindrical groove, so as to realize the fixed connection of the drive rod in the inner barrel.

[0098]The mop includes a rod body 4, a Y-shaped piece 9, a T-joint 10, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com