Measuring instrument for guide pipe hole coaxiality/valve seat ring roundness of valve seat of cylinder cover of engine

A technology for engine cylinder heads and valve seats, which is applied to instruments, measuring devices, and fluid devices, etc., can solve problems such as short life, achieve low cost, reduce impact, and facilitate model change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

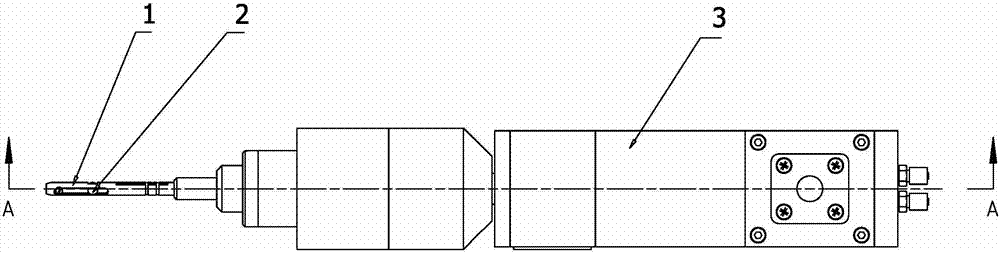

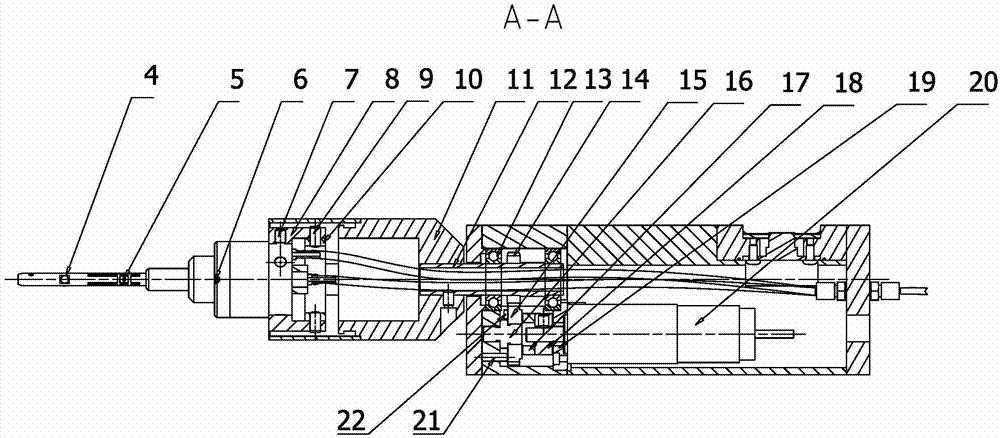

[0018] Such as figure 1 , figure 2 As shown, it includes probe 1, elastic point 2, valve seat shell 3, fixed point 4, conduit air nozzle 5, valve seat air nozzle 6, set screw 7, swing ring 8, pin shaft 9, connecting copper sleeve 10 , fixed sleeve 11, main shaft 12, bearing 13, driven gear 14, driving gear 15, gear shaft 16, cross sliding sleeve 17, connecting sleeve 18, positioning ring 19, motor 20, angle limit shaft 21, driving gear boss 22 etc.

[0019] Such as figure 1 , 2 As shown, a gauge body of the present invention includes a valve seat housing 3, a main shaft 12 is rotatably arranged in the shaft hole of the valve seat housing 3, and the front end of the main shaft 12 protrudes from the valve seat housing 3, and is positioned on the main shaft 12 protruding from the end shaft diameter of the valve seat housing 3 and fastening the fixed sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com