Through hole filling method during making of oxygen sensor

A sensor and a technology for producing oxygen, which is applied to instruments, scientific instruments, and material analysis through electromagnetic means, etc., can solve the problems that the electrodes 11 cannot be connected effectively, the product is unqualified, and cannot be repaired, so as to achieve effective and stable connection and pass rate Improvement and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

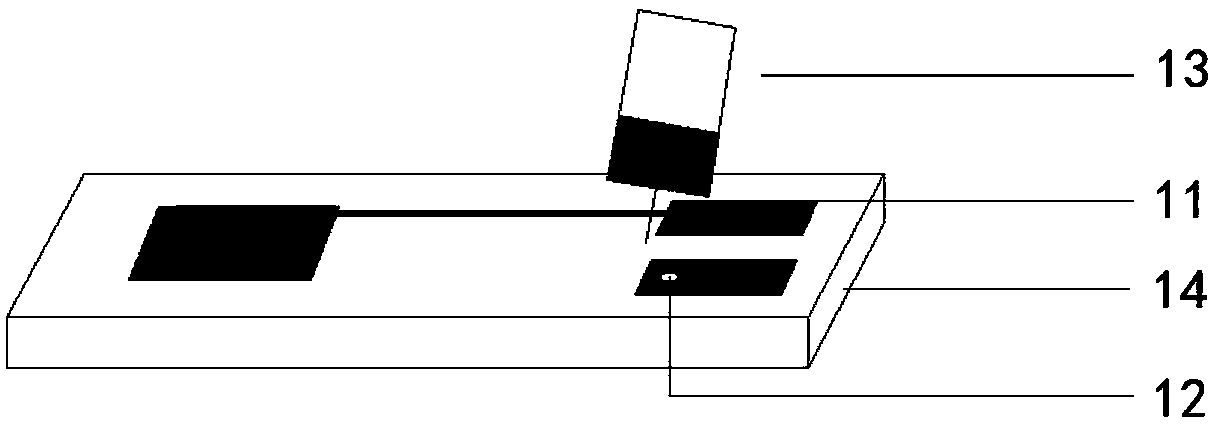

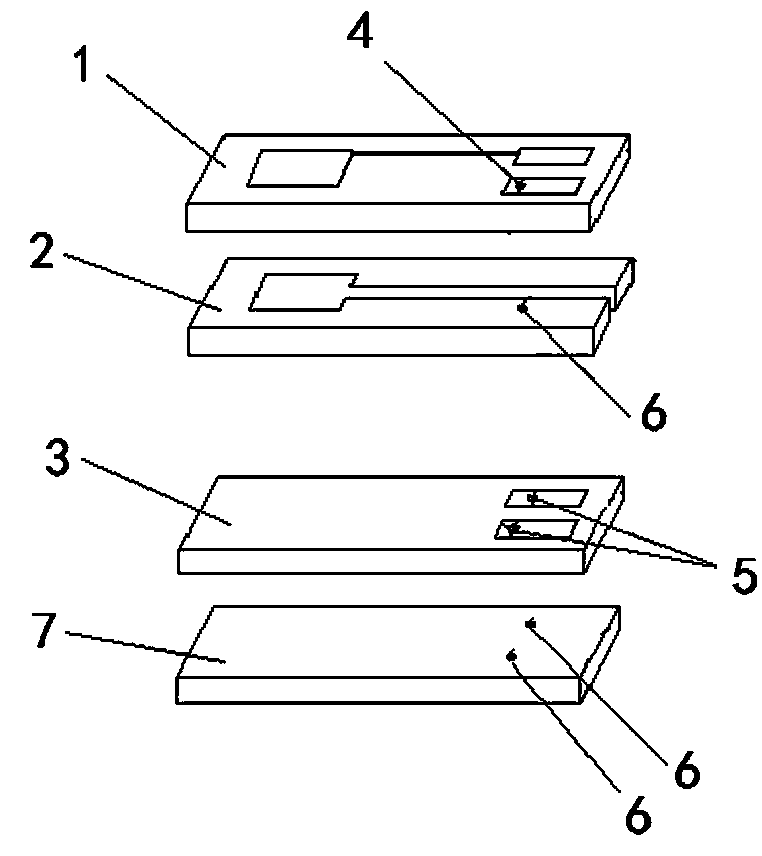

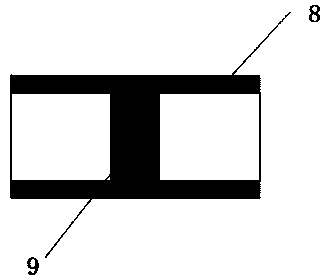

[0018] figure 2 It shows an embodiment of a method of filling through holes for manufacturing an oxygen sensor according to the present invention, which includes a functional layer 1, an air channel layer 2 and a heating electrode layer 3 that sequentially form an oxygen sensor up and down, and the upper surface of the functional layer 1 is provided with Internal electrode via holes 4, two heating electrode via holes 5 are provided on the upper surface of the heating electrode layer 3, and a metal layer is printed on the upper surface of the air channel layer 2 corresponding to the inner electrode via holes 4 of the functional layer 6. A white sheet layer 7 is arranged directly below the heating electrode layer 3, and two metal layers 6 are respectively printed on the upper surface of the white sheet layer 7 corresponding to the two heating electrode via holes 5 of the heating electrode layer 3, and the functional layer 1 After being laminated with the air channel layer 2, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com