Metal anti-fake identification method based on ultrasonic backscattering attenuation coefficient spectrum

A technology of ultrasonic backscattering and attenuation coefficient, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and prepare samples for testing. It can solve the problems of metal product damage, high cost, and complicated identification methods, and achieve low cost, The effect of fast recognition speed and easy online identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using the 420 stainless iron metal product with a known mark as the reference sample, based on the ultrasonic backscatter attenuation coefficient spectrum, the anti-counterfeiting identification of the samples numbered 1#, 2#, and 3# are carried out. The specific method is realized by the following steps:

[0036] The 420 stainless iron metal products are mixed with the other two metal samples of 304 stainless steel and aluminum 2A12. They are cylindrical in shape, with a thickness of 15mm and a diameter of 47.1mm. The sample numbers to be tested are shown in the table 1 shown.

[0037] Table 1 Sample table of samples to be tested

[0038] Numbering

Material category

1#

304 stainless steel

2#

Aluminum 2A12

3#

420 stainless iron

[0039] (1) Pretreatment of reference sample

[0040] The reference sample of the known standard 420 stainless iron material was pretreated and processed into a cylindrical structure with a thickness of 15mm and a diameter of 47.1mm. The u...

Embodiment 2

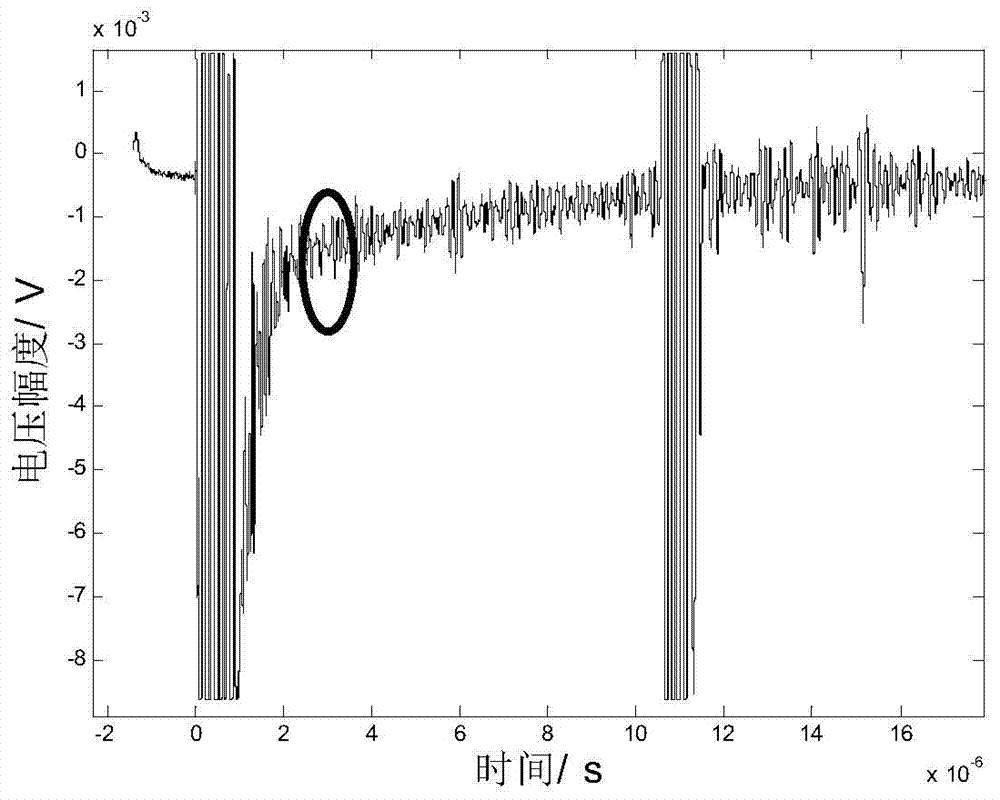

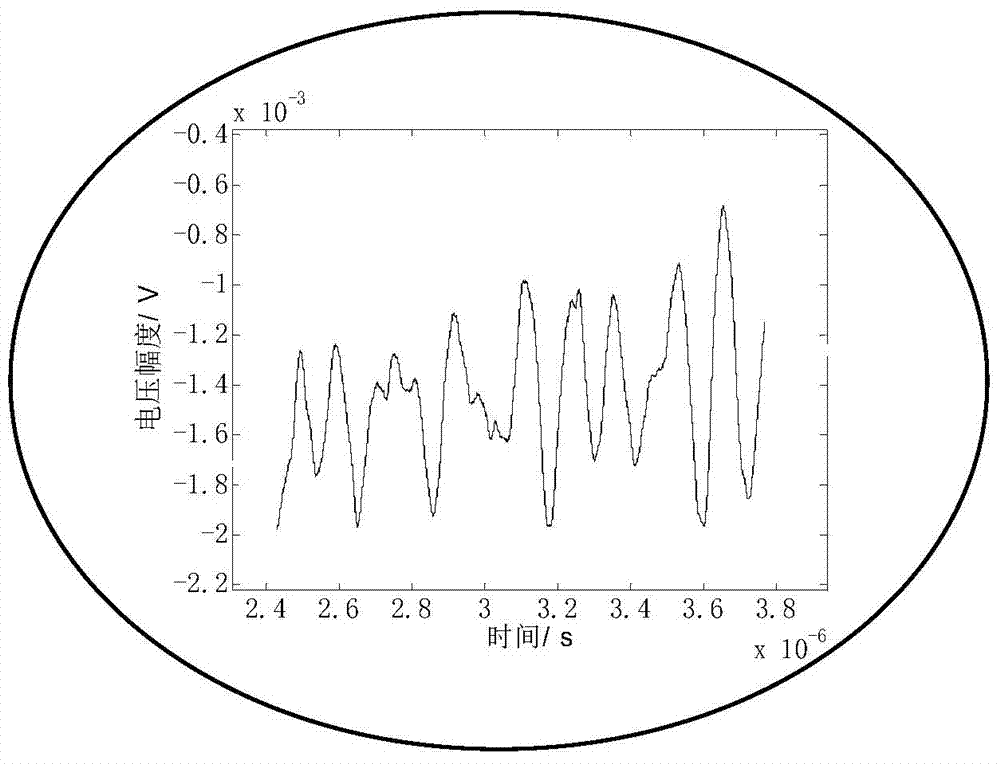

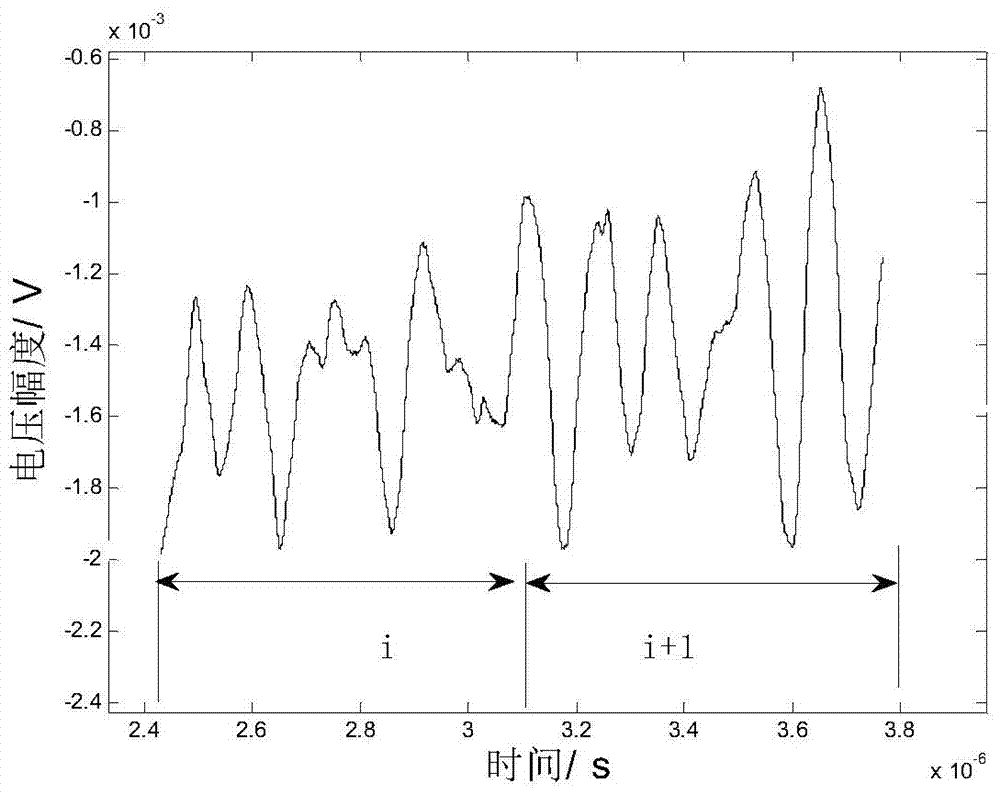

[0068] In the metal anti-counterfeiting identification method based on the ultrasonic backscatter attenuation coefficient spectrum of this embodiment, the reference sample selected in step (1) is a cuboid with a thickness of 3 mm and a length × width of 40 × 30 mm, and the surface is polished and cleaned. . In step (2), choose a commercially available 5077PR pulse receiver / transmitter, connect it to the transceiver probe, Tektronix-DPO5034B digital oscilloscope, connect the oscilloscope to the computer, select a transceiver probe with a center frequency of 5MHz, and other operations and implementations Example 1 is the same. Step (3) Extract the scattered signal between the initial wave and the first bottom echo in the time domain waveform, intercept the local scattered signal f(t), and intercept the time domain width as T, and divide f(t) into N equal parts , N is 5, which can be adjusted according to the actual situation, corresponding to f(t i ), where 1≤i≤N, take any adjac...

Embodiment 3

[0071] In the metal anti-counterfeiting identification method based on the ultrasonic backscatter attenuation coefficient spectrum of this embodiment, the reference sample selected in step (1) is a rectangular parallelepiped with a thickness of 10 mm and a length × width of 30 × 25 mm, and the surface is polished and cleaned. . In step (2), select a commercially available 5077PR pulse receiver / transmitter, connect it to the transceiver probe, Tektronix-DPO5034B digital oscilloscope, connect the oscilloscope to the computer, select a transceiver probe with a center frequency of 20MHz, and other operations and implementations Example 1 is the same. Step (3) Extract the scattering signal between the initial wave and the first bottom echo in the time domain waveform, intercept the local scattering signal f(t) in the time domain scattering signal, and divide f(t) into 10 equal parts , Corresponding to f(t i ), where 1≤i≤N, take any adjacent two equal parts i and i+1, add Hanning wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com