Method for identifying multiple metals by utilizing ultrasonic non-destructive detection method

A non-destructive detection and metal technology, which is applied in the preparation of test samples and the analysis of solids using sound waves/ultrasonic waves/infrasonic waves. It can solve problems such as complex, complex chemical methods, and damage to metal products. Accurate and reasonable identification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking stainless steel, 304 stainless steel and 2A13 aluminum alloy as examples, the method of identifying these three metals by ultrasonic nondestructive detection consists of the following steps:

[0024] (1) Polish and clean the rectangular stainless steel, 304 stainless steel and 2A13 aluminum alloy reference samples with a thickness of 30mm respectively;

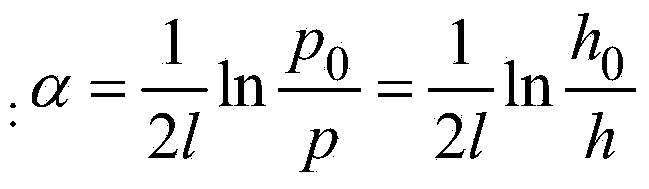

[0025] (2) Fix the transceiver probes with a frequency f1 of 5MHz on the surfaces of the above three reference samples respectively, transmit a pulse signal with a frequency of 5MHz and collect the bottom reflection signals of the three reference samples. This example uses a commercially available 5077PR pulse Transmitting receiver and Puyuan RIGOL DS1052E digital oscilloscope process the collected reflection signal and send it to the computer for further processing, and measure and calculate the sound velocity, sound attenuation coefficient and primary bottom echo in the amplitude spectrum of each reference sampl...

Embodiment 2

[0048] Now take the stainless iron sample as an example, put it at room temperature, 800°C|260°C / h↑|6h (heating treatment at 260°C per hour, heat preservation for 6 hours when the temperature rises to 800°C, natural cooling), 900°C| 260°C / h↑|6h (heat treatment at 260°C per hour, heat preservation for 6 hours when the temperature rises to 900°C, and natural cooling) Three samples under three heat treatment conditions were identified by ultrasonic non-destructive detection method. The method is as follows The steps consist of:

[0049] (1) For the known stainless iron reference samples under normal temperature conditions, the stainless iron reference samples under the conditions of 800°C|260°C / h↑|6h, and the conditions of 900°C|260°C / h↑|6h The surface of the stainless steel reference samples was polished and cleaned respectively.

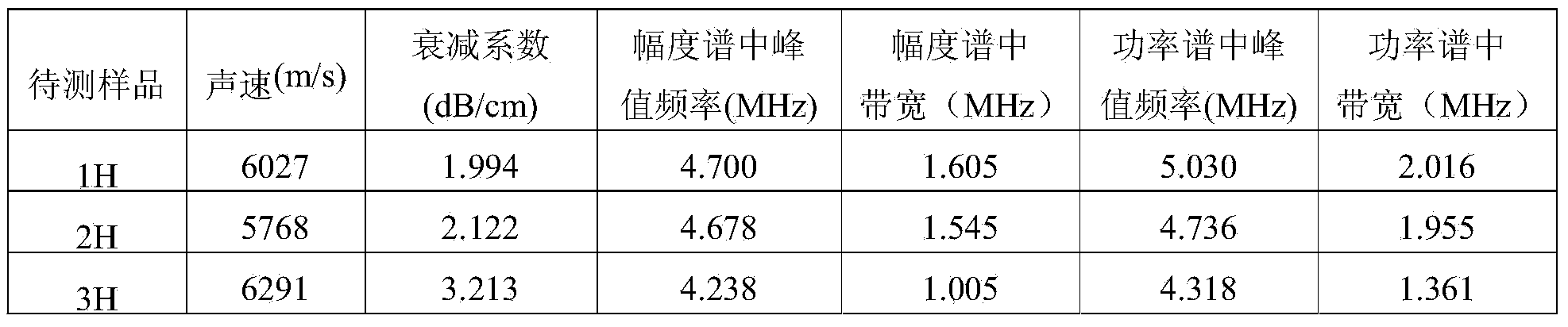

[0050] (3) Take samples 1H-1, 1H-2, and 1H-3 as samples to be tested, and grind and clean their surfaces respectively so that the surface roughness ...

Embodiment 3

[0054] In step (2), the transceiver probes with a frequency f1 of 2.5 MHz are respectively fixed on the surfaces of the above three reference samples, a pulse signal with a frequency of 2.5 MHz is transmitted and the bottom reflection signals of the three reference samples are collected, measured and calculated The sound velocity, sound attenuation coefficient, peak frequency and bandwidth of a back-wall echo in the amplitude spectrum and the peak frequency and bandwidth of a back-wall echo in the power spectrum of each reference sample are obtained. In step (5), use a transceiver probe with a frequency f2 of 5 MHz, repeat steps (2) and (3), and obtain the sound velocity, sound attenuation coefficient, and amplitude spectrum of the reference sample and the sample to be tested under the condition of f2. The peak frequency and bandwidth of a backwall echo and the peak frequency and bandwidth of a backwall echo in the power spectrum are compared again with the parameters of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com