Method for identifying true and false metal by ultrasonic non-destructive detection method

A non-destructive detection and metal technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of metal product damage, complexity, and complex chemical methods, and achieve low cost, simple identification methods, and accurate and reasonable identification results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

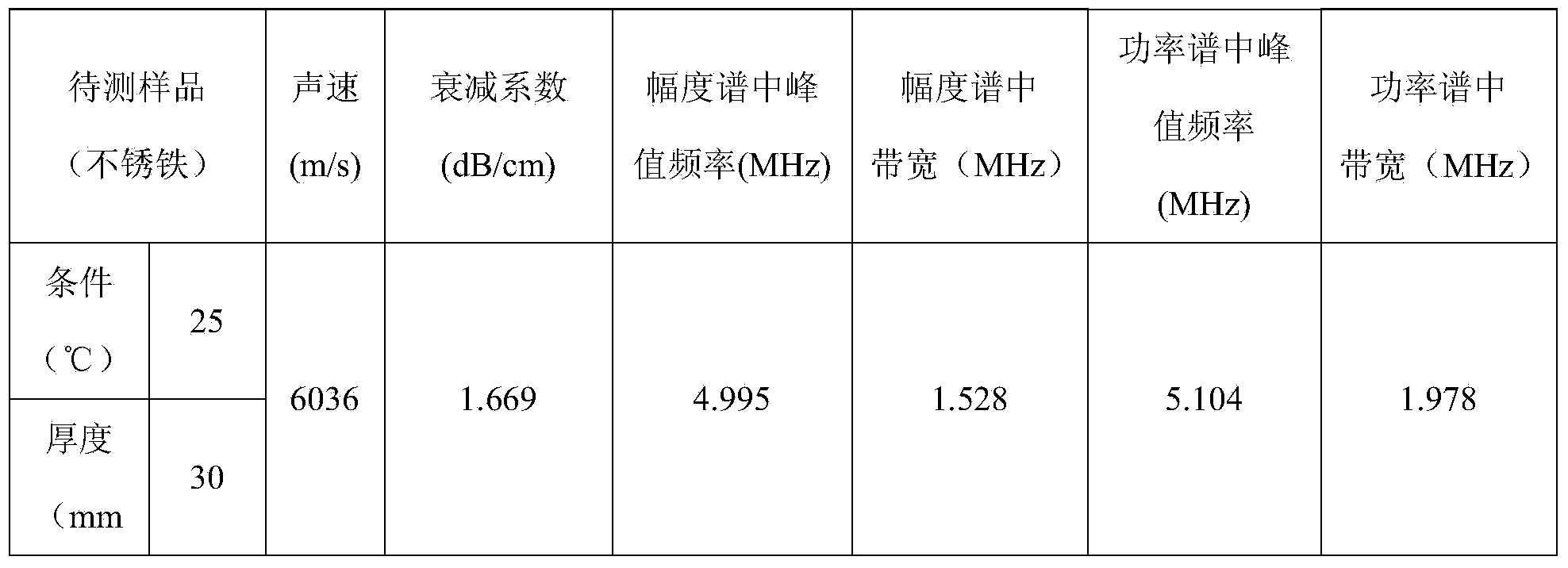

[0023] Taking stainless iron metal products as an example, the method of using ultrasonic non-destructive detection to identify the authenticity of metal consists of the following steps:

[0024] (1) Polish the upper and lower surfaces of the rectangular stainless iron reference sample with a thickness of 30 mm and rinse it with clean water.

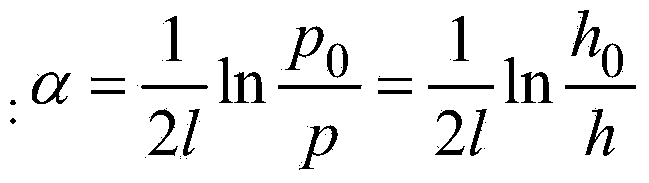

[0025] (2) Fix the transceiver probe with a frequency of 5MHz on the upper surface of the above-mentioned stainless iron reference sample, transmit a pulse signal with a frequency of 5MHz and collect the bottom surface reflection signal of the stainless iron reference sample. In this embodiment, a commercially available The 5077PR pulse transmitter receiver and Puyuan RIGOL DS1052E digital oscilloscope process the collected reflection signals and send them to the computer for further processing, and use conventional calculation methods to calculate the corresponding acoustic parameters of the stainless steel reference sample, namely sound...

Embodiment 2

[0042] In step (2) and step (3), a transceiver probe with a frequency of 2.5MHz is used to collect the bottom reflection signals of the stainless iron reference sample and the sample to be tested, and the rest of the operations are the same as in Example 1.

[0043] Other steps are the same as in Example 1.

Embodiment 3

[0045] In step (2) and step (3), a transceiver probe with a frequency of 7.5 MHz is used to collect the bottom surface reflection signals of the stainless iron reference sample and the sample to be tested, and the rest of the operations are the same as in Example 1.

[0046] Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com