Medicine loading method for automatic medicine management system

A technology for automatic management of medicines, applied in storage devices, transportation and packaging, etc., can solve the problems of falling medicine boxes, medicine damage, etc., to achieve the effect of not easy to fall, avoid medicine damage, and push accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

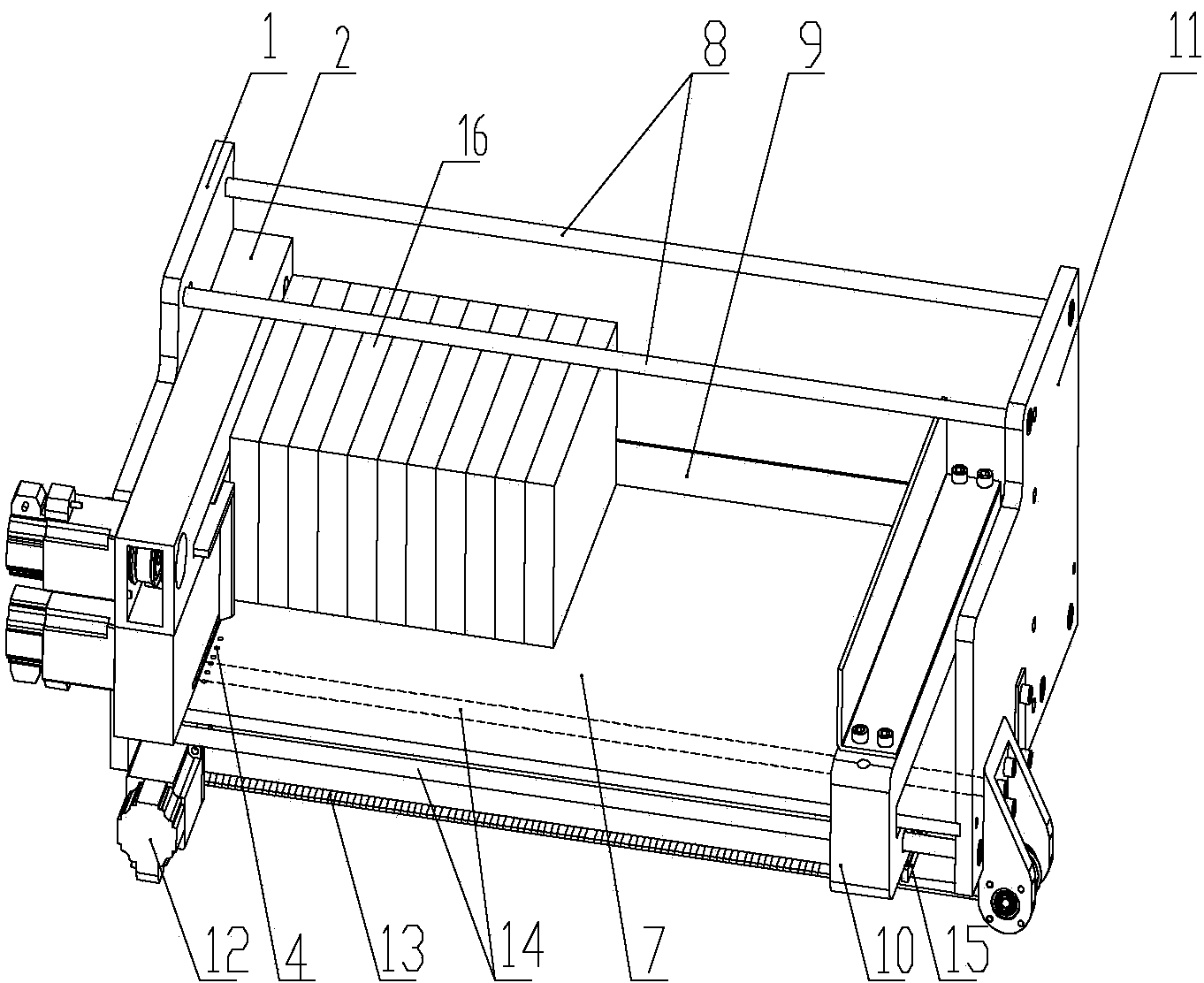

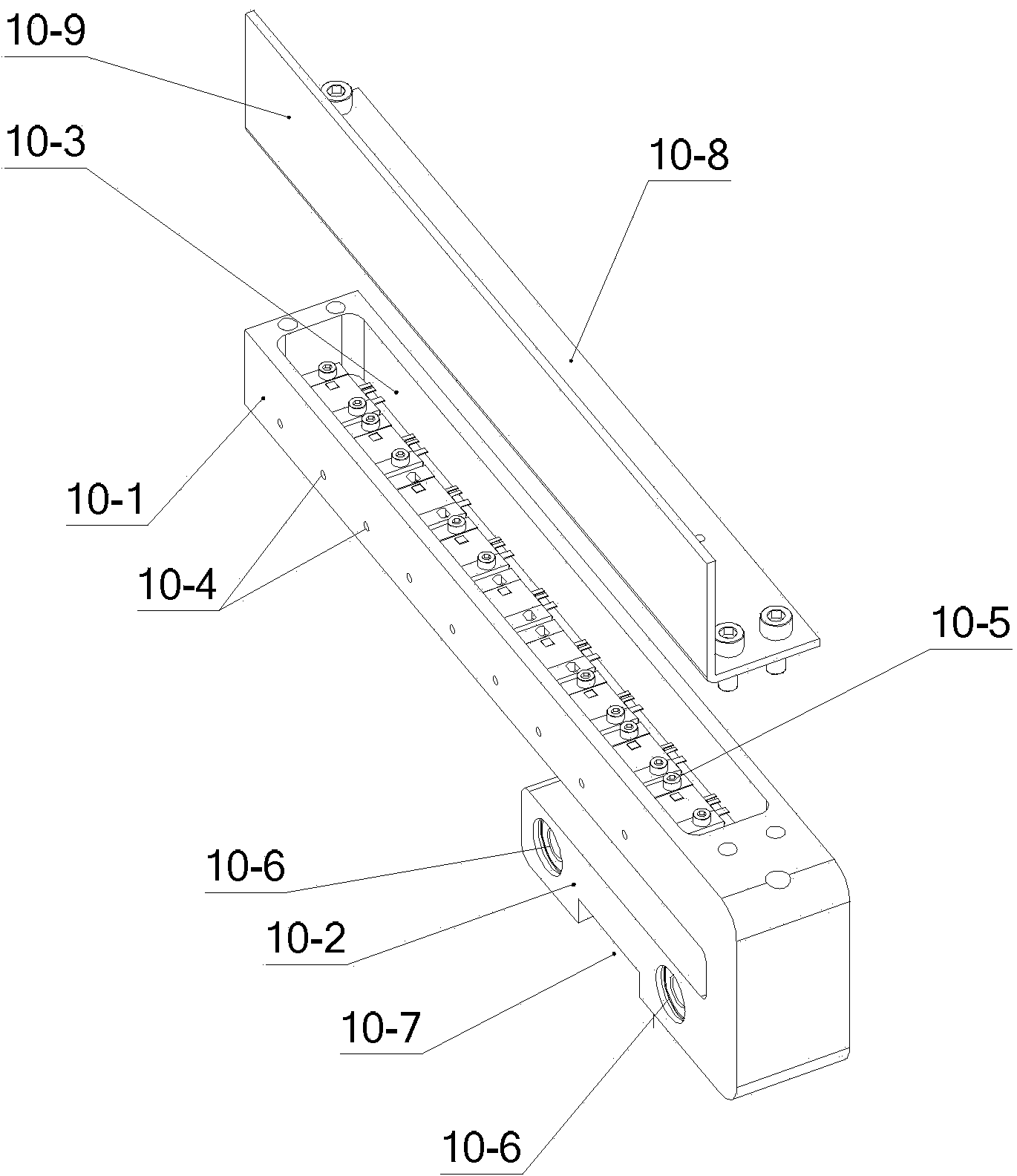

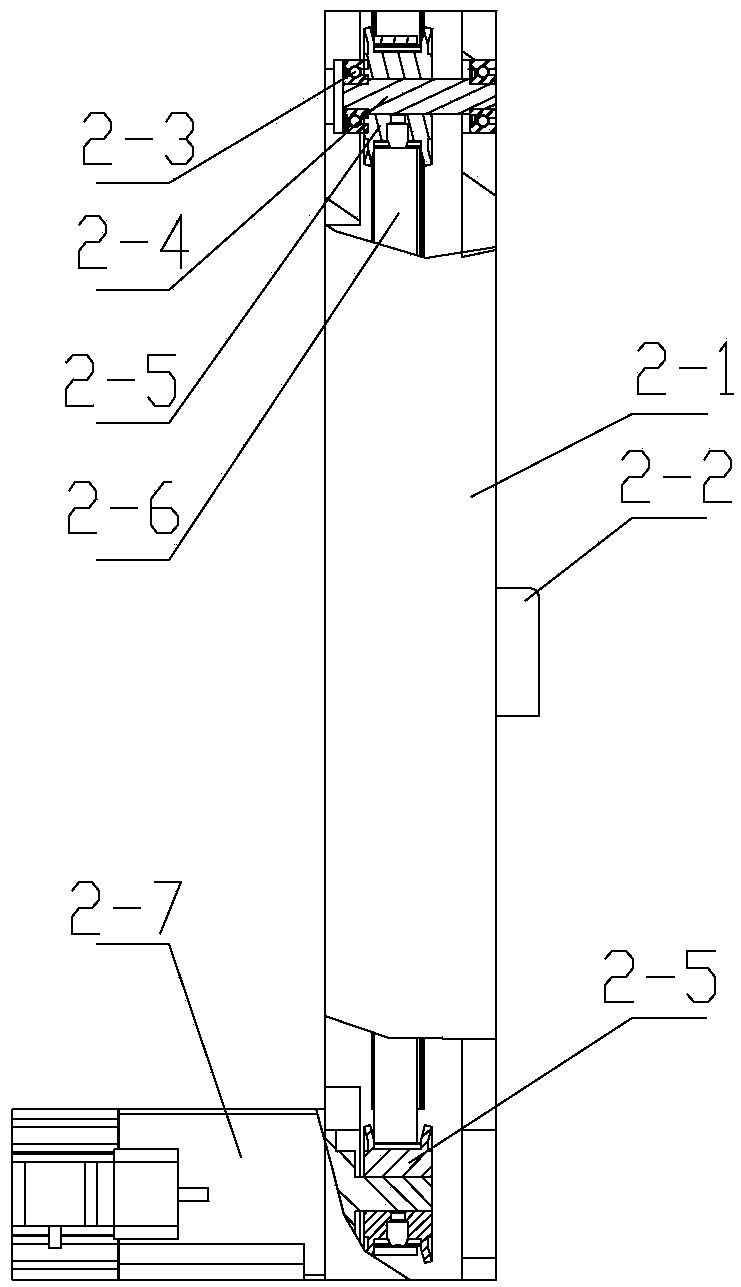

[0023] Specific implementation mode one: refer to figure 1 , 2 , 3 and 4 illustrate this embodiment, a drug loading method in an automatic drug management system described in this embodiment, the method is realized based on a drug loading system in an automatic drug management system, the drug The drug loading system in the automatic management system includes a push device 2, a bottom plate 7, a left baffle 1, a right baffle 11, a guide rod 8, a medicine box baffle 9, a U-shaped frame pressing mechanism 10, two parallel lower Slide rail 14, transverse movement motor 12, transverse synchronous belt 13 and transverse synchronous belt loading part 15,

[0024] Left baffle plate 1 and right baffle plate 11 are respectively positioned at the left and right sides of base plate 7, and medicine box shielding plate 9 is positioned at the rear end of base plate 7, and left baffle plate 1, right baffle plate 11, base plate 7 and medicine box shielding plate 9 enclose The area is the m...

specific Embodiment approach 2

[0036] Specific embodiment 2: This embodiment is a further description of the drug loading method in a drug automatic management system described in specific embodiment 1. In this embodiment, in step 1, the drug box is placed on the bottom plate 7, and the The lateral movement motor 12 drives the U-shaped frame pressing mechanism 10 to move to the left, and the process of compressing the medicine box on the base plate 7 between the U-shaped frame pressing mechanism 10 and the pushing device 2 is as follows:

[0037]Control lateral moving motor 12 to drive U-shaped frame pressing mechanism 10 to move to the left, when detecting that all photoelectric sensors on the U-shaped frame pressing mechanism 10 are blocked, begin to detect the photoelectric switch array in the initial photoelectric switch array of base plate 7 bottoms. The state of the photoelectric sensor, when all the photoelectric sensors of the initial photoelectric switch array are blocked, the control lateral moveme...

specific Embodiment approach 3

[0038] Specific embodiment three: This embodiment is a further description of the drug loading method in a drug automatic management system described in specific embodiment two. In this embodiment, after detecting that all photoelectric sensors of the initial photoelectric switch array are When being blocked, monitor the operating current of the laterally moving motor 12, and when it is detected that the operating current has a sudden change, then control the laterally moving motor 12 to stop working, and the medicine box is clamped to the U-shaped frame pressing mechanism 10 and the pushing device 2 between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com