Manual hoisting chain block

A technology of chain-reversing and driving sprocket, which is applied in portable hoisting devices, hoisting devices, etc., which can solve the problems of increased labor intensity of workers, inconvenient use and installation, and complex chain-reversing structure, and achieves light weight and convenient installation , Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

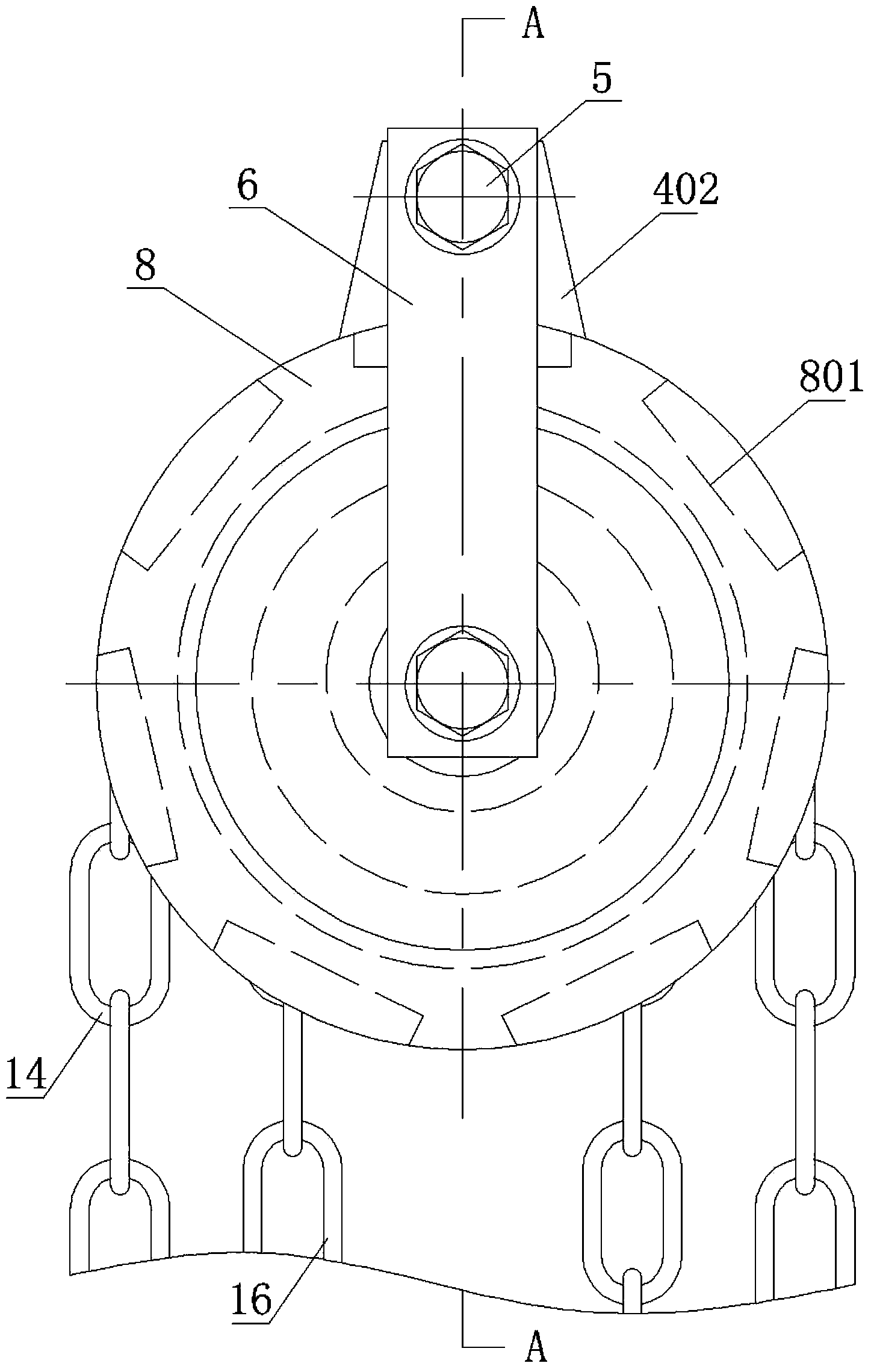

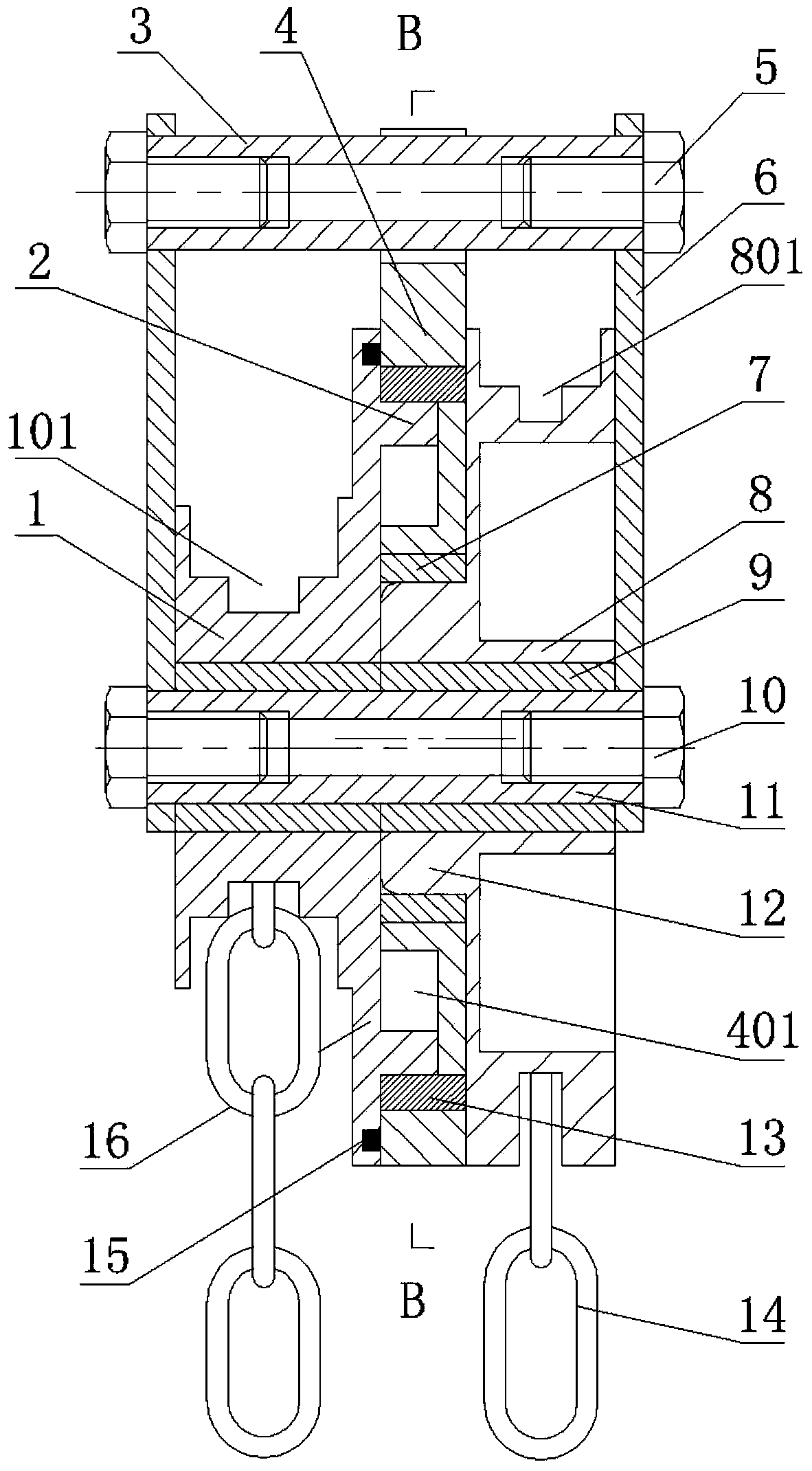

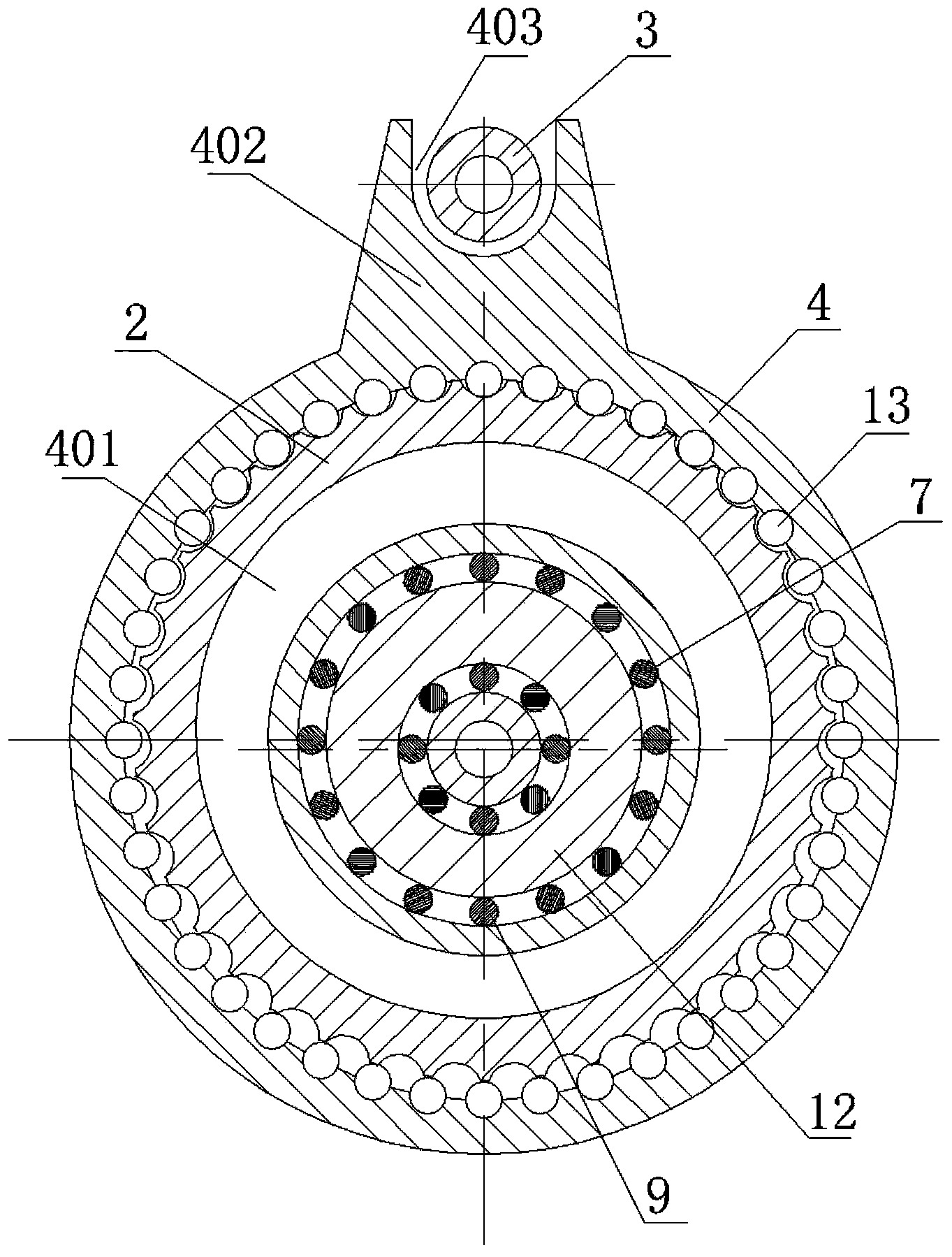

[0022] Such as Figure 1-Figure 3 As shown, a kind of manual lifting chain involved in the present invention includes driving sprocket 8 and driven sprocket 1, and ring-shaped chain grooves 801 and 101 are respectively provided on driving sprocket 8 and driven sprocket 1, An annular closed driving chain 14 and a lifting chain 16 are respectively arranged in the annular chain grooves 801 and 101 of the driving sprocket 8 and the driven sprocket 1 . An eccentric sleeve 12 is arranged on the side of the driving sprocket 8 corresponding to the driven sprocket 1, and the eccentric sleeve 12 and the driving sprocket 8 are integrally structured, and a pin tooth is arranged between the driving sprocket 8 and the driven sprocket 1. The sleeve 4, the eccentric sleeve 12 is inserted into the central hole of the pin tooth sleeve 4, and a needle bearing B7 is installed between the eccentric sleeve 12 and the central hole of the pin gear sleeve 4.

[0023] An annular groove 401 is processe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap