Method for preparing methanol from high-sulfur coal

A high-sulfur coal and methanol technology, applied in the field of coal chemical industry, achieves the effect of difficult operation, large reserves, and simplified methanol production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

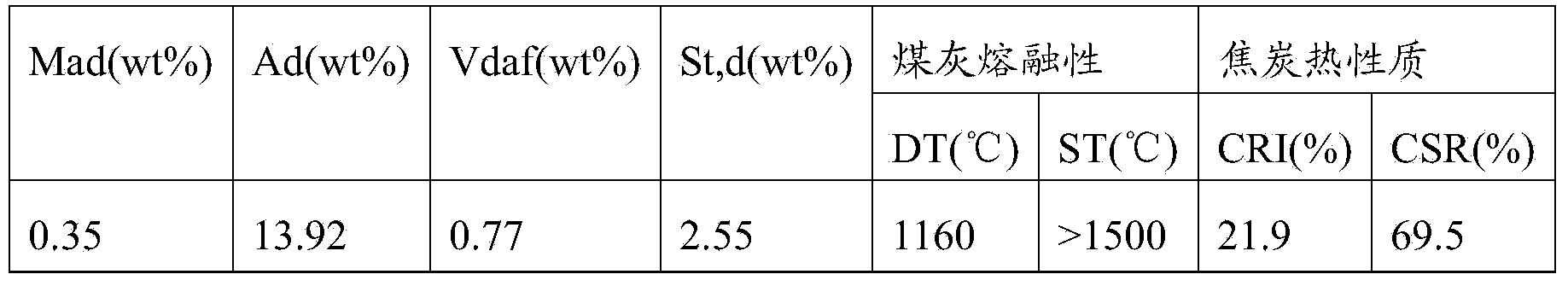

[0036] The high-sulfur coal is all raw materials for coking, and the coking conditions are: coking temperature 1300-1320°C; coking time 22-23h, to obtain coke (see Table 2 for the quality analysis of the obtained coke).

[0037] Table 2

[0038]

Embodiment 2

[0040] The coke obtained in Example 1 is further sent into a gasification furnace for gasification treatment. The gasification treatment conditions are: using 5-55mm coke blocks as raw materials, water vapor and oxygen as gasification agents, at an average pressure of about 3.2MPa, an average Under the condition of a temperature of about 1280°C, the gasification reaction is carried out to generate crude gas, wherein the amount of water vapor used is 1.8 tons / ton of coke, and the amount of oxygen used is 470Nm 3 / ton of coke. The crude gas was washed with water and methanol to remove dust, tar, sulfur and other substances that are not conducive to methanol synthesis. The main components of the purified gas are shown in Table 3. The effective gas content is 90%; the coke conversion rate is 95%.

[0041] table 3

[0042] CO

Embodiment 3

[0044] The coke obtained in Example 1 is further sent into the Lurgi gasifier for gasification treatment. The gasification treatment conditions are: using 5-55mm coke blocks as raw materials, using water vapor and oxygen as gasification agents, at an average pressure of about 3.5MPa , Under the condition of an average temperature of about 1250°C, the gasification reaction is carried out to generate crude gas, wherein the amount of the water vapor is 1.85 tons / ton of coke, and the amount of the oxygen is 480Nm 3 / ton of coke. The crude gas is washed and desulfurized by Claus to remove dust, tar, sulfur and other substances that are not conducive to methanol synthesis to obtain purified gas, in which the effective gas content is 92% and the coke conversion rate is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com