Multi-way reversing valve

A reversing valve and channel technology, applied in the field of reversing valves, can solve the problems of reducing extraction efficiency, multi-way reversing valves cannot use continuous extraction process, and increase extraction costs, so as to achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The making and using of embodiments of the invention are discussed in detail below. It should be appreciated, however, that the embodiments provide many applicable inventive concepts that can be embodied in a wide variety of specific contexts. The specific embodiments discussed are illustrative only, and do not limit the scope of the invention.

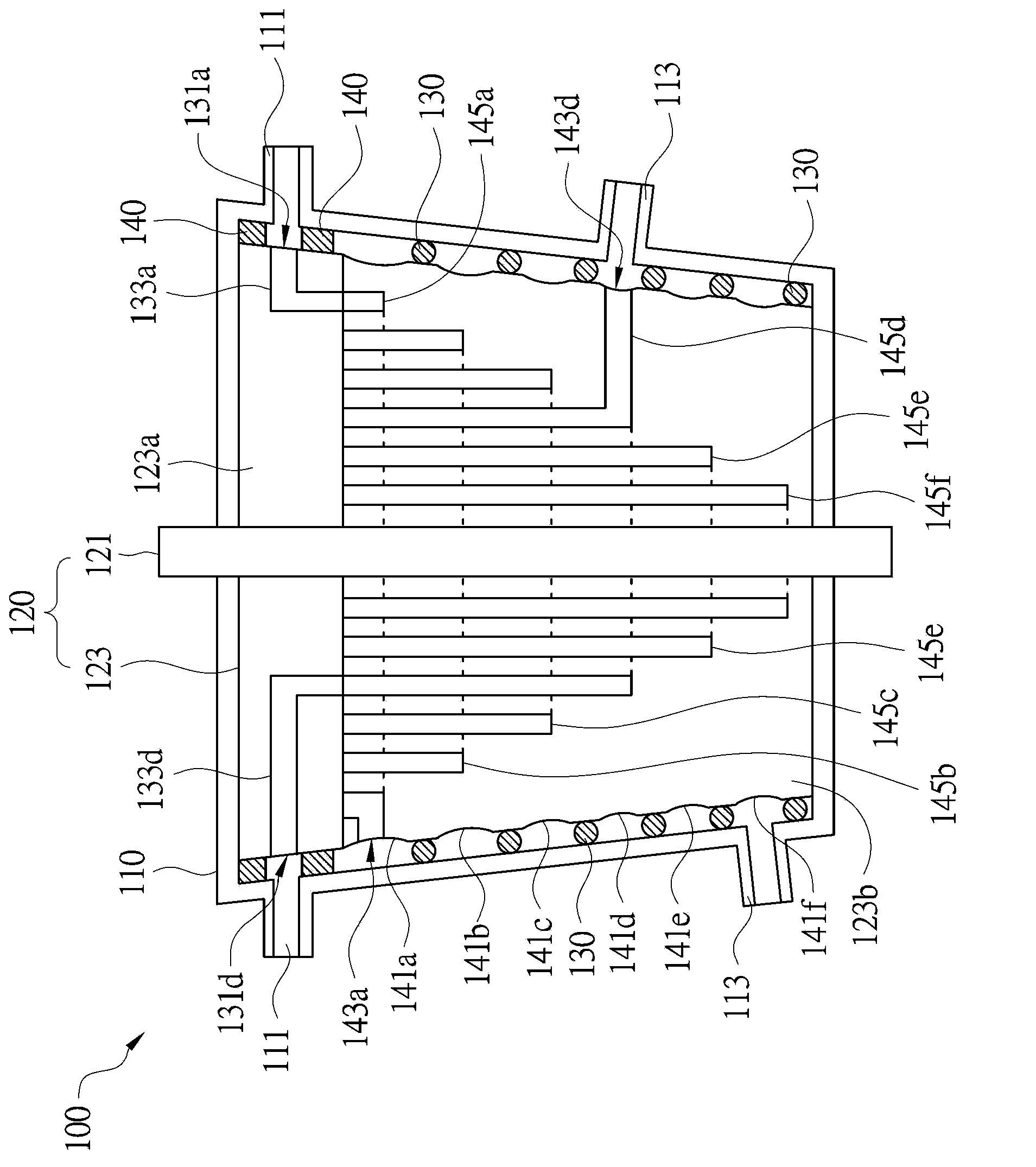

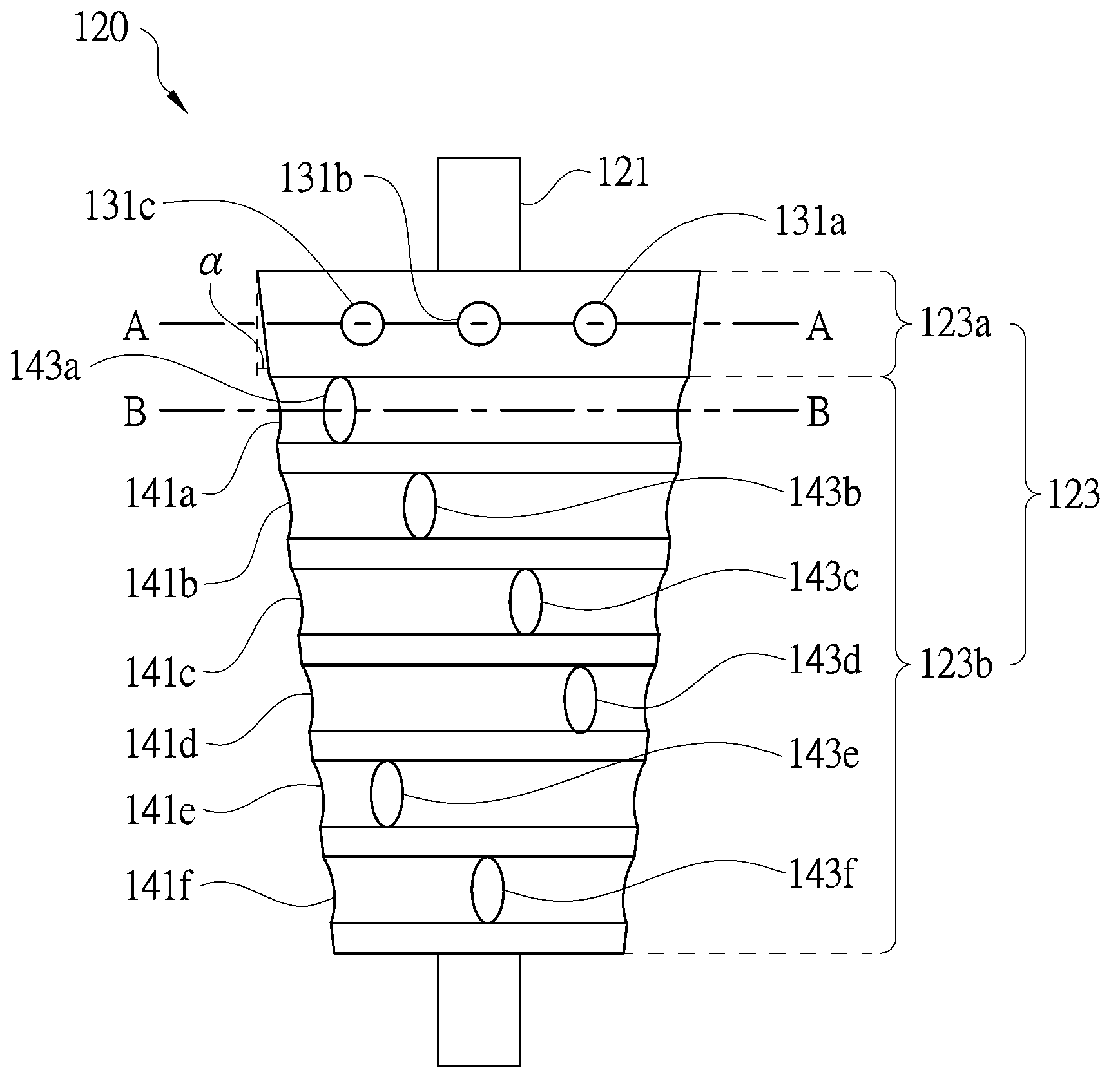

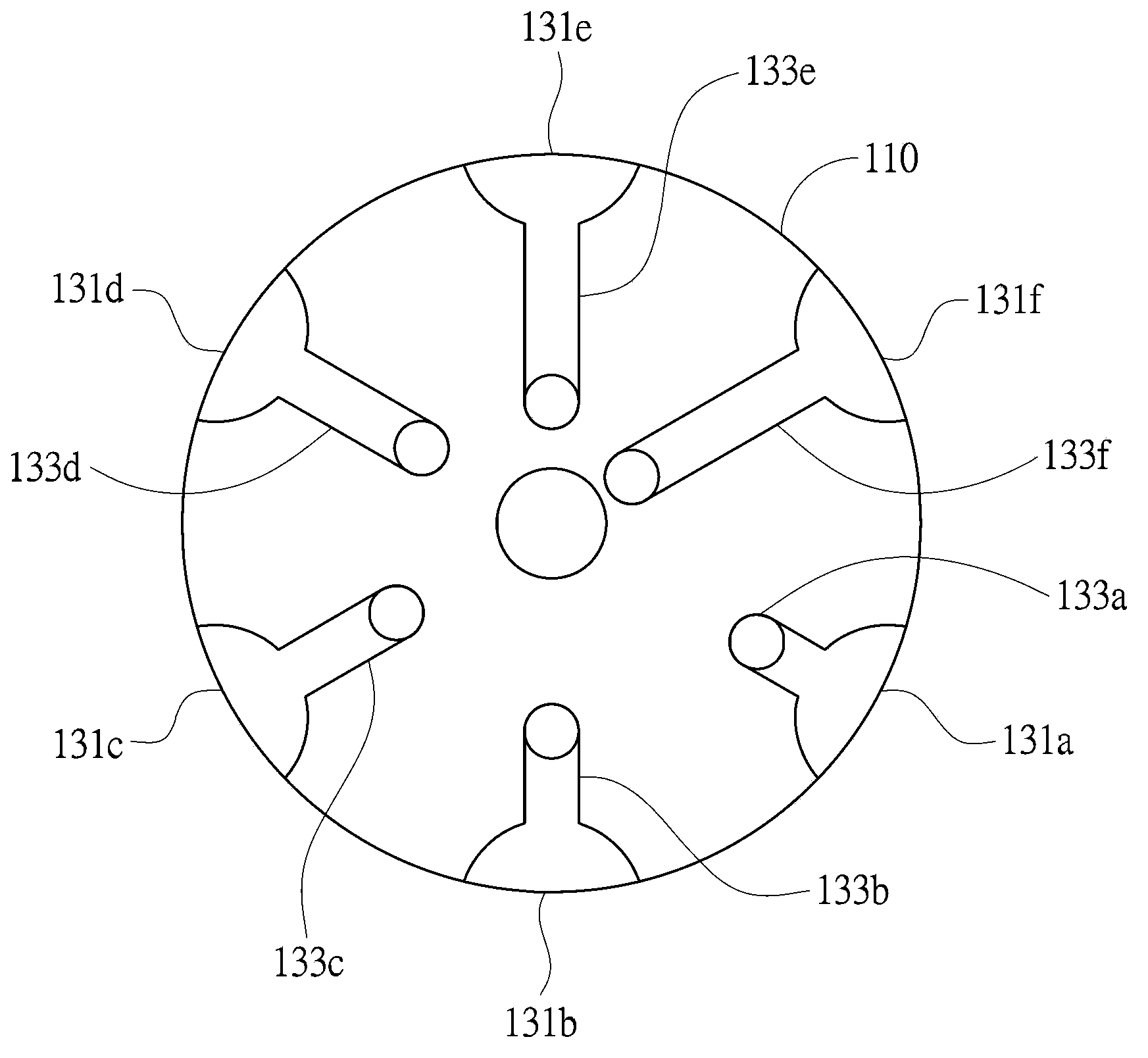

[0041] Please refer to Figures 1a to 1d ,in Figure 1a To illustrate a cross-sectional view of a multi-way reversing valve according to an embodiment of the present invention, Figure 1b A side view showing the structure of the rotary core of the multi-way reversing valve according to an embodiment of the present invention, Figure 1c drawn along Figure 1b A cross-sectional view of the input section cut by section line A-A, while Figure 1d to show along Figure 1b A top view of the output section taken along the middle section line B-B. In one embodiment, Figure 1a The multi-way reversing valve 100 includes a casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com