an expansion valve

The technology of an expansion valve and a valve cavity is applied in the field of an expansion valve for automobile air conditioners, which can solve the problems of capillary damage, easy rupture of the capillary, and failure of the expansion valve to work normally, and achieves the effect of ensuring the reliability of vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

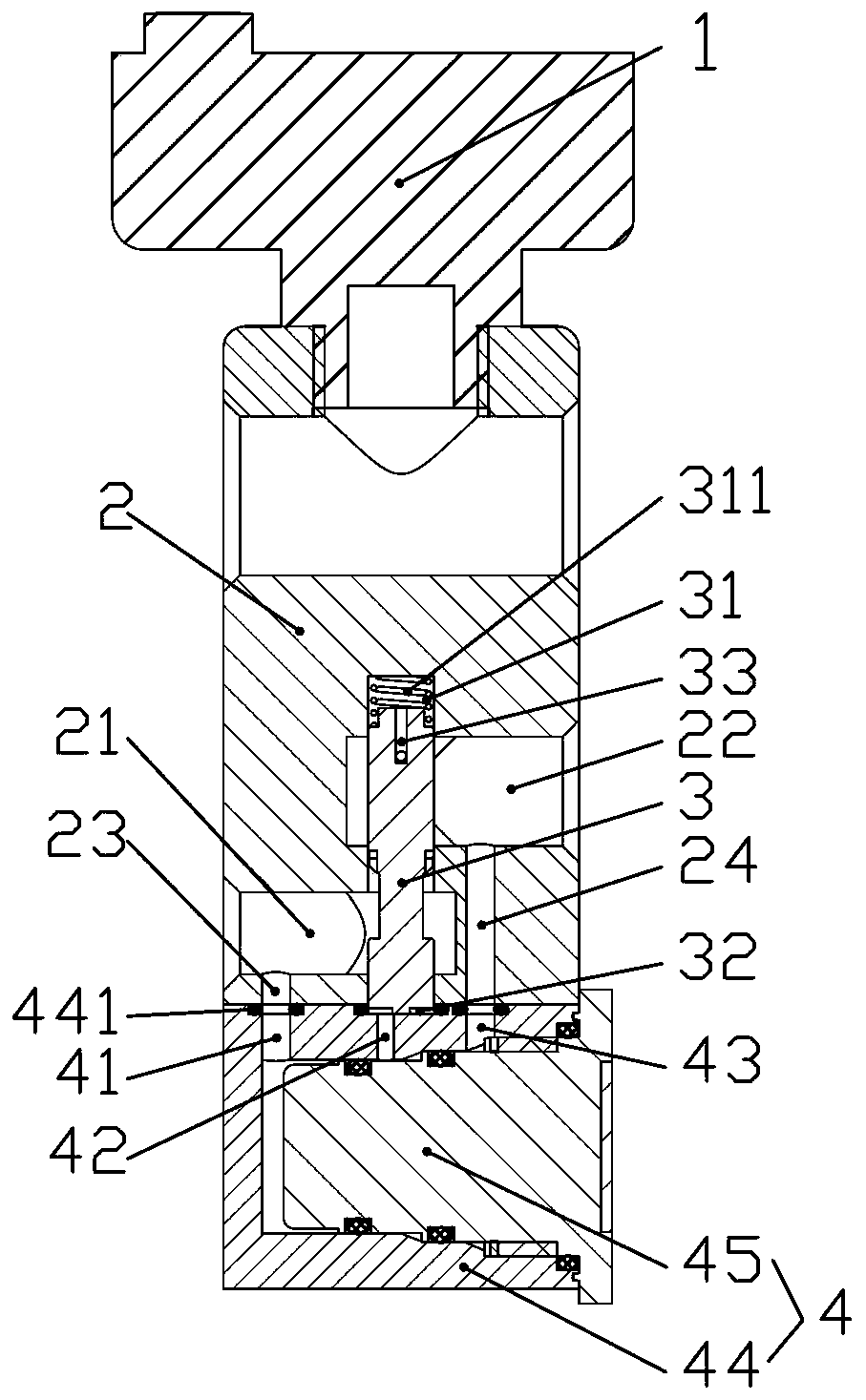

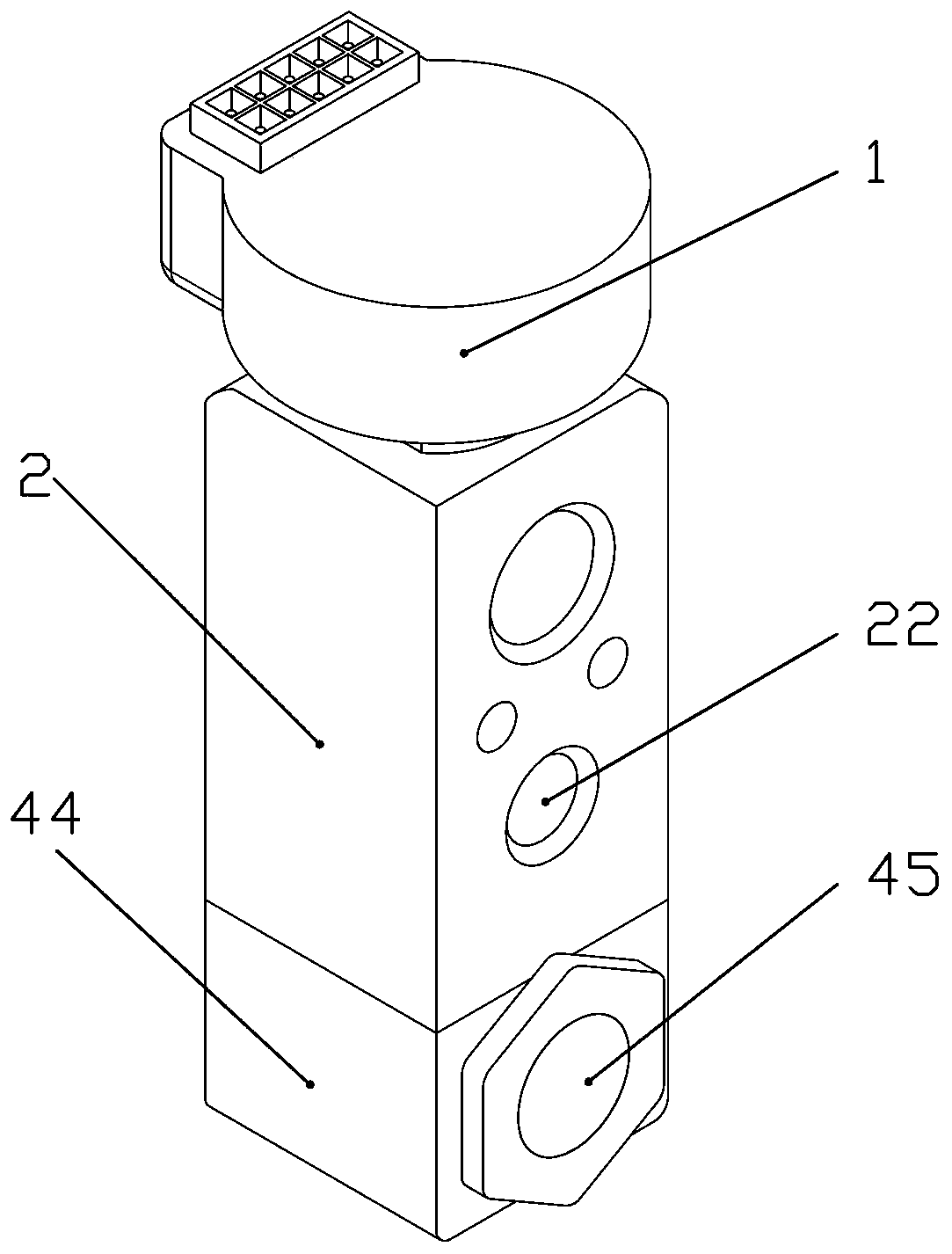

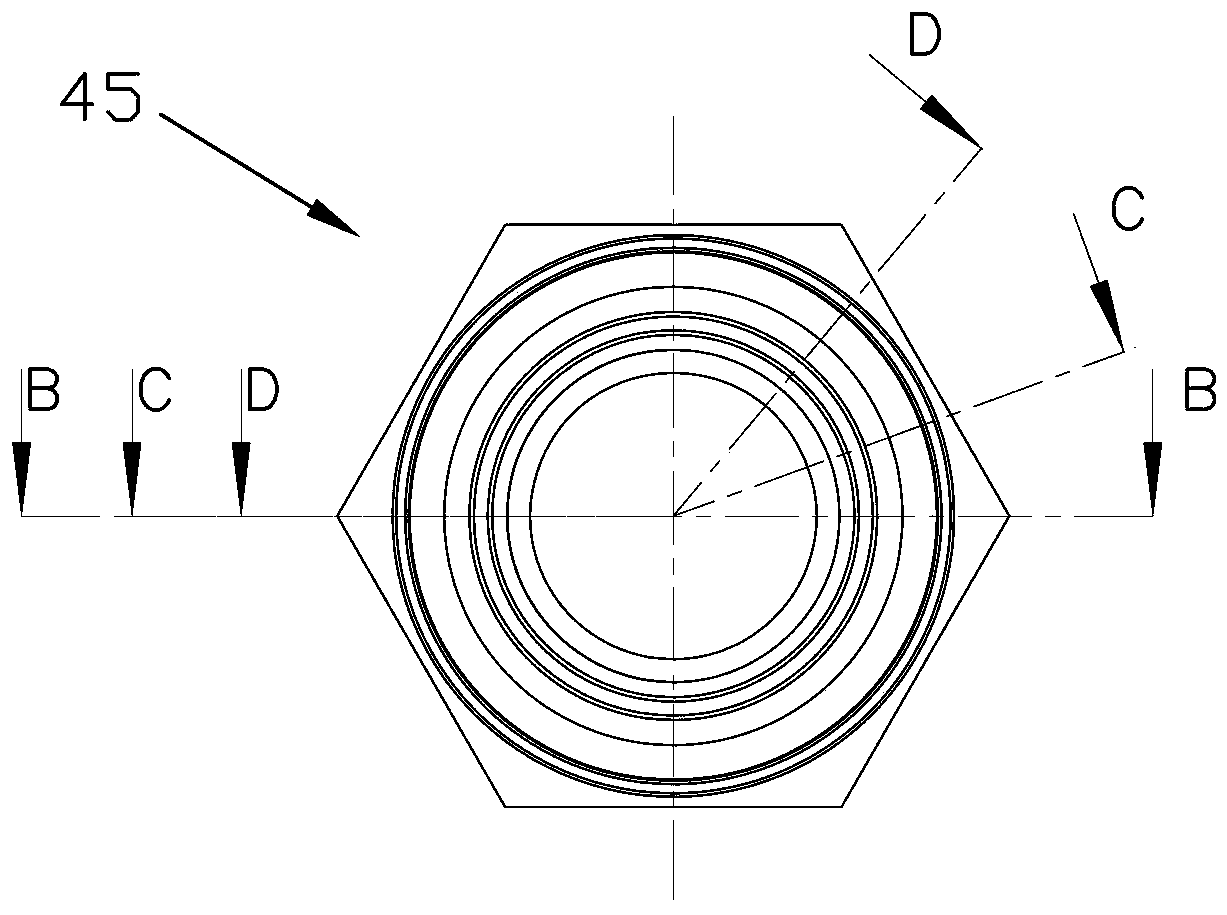

[0033] refer to Figure 1 to Figure 7 , an expansion valve, comprising a main valve body 2, a valve cavity is arranged in the main valve body 2, a main inlet 21 and a main outlet 22 are opened in the valve cavity, a valve core 3 is housed in the valve cavity, and the valve core 3 divides the valve cavity into The upper cavity 31 and the lower cavity 32 are not communicated with each other. The upper cavity 31 is provided with a spring 311 to push the valve core 33 downward. The upper end of the valve core 3 has a pressure relief hole 33 communicating with the main outlet 22. A pilot valve 4 is provided with a microvalve 5 on the pilot valve. The pilot valve 4 is provided with a branch inlet 41, a pilot valve port 42 and a branch outlet 43. The branch inlet 41 communicates with the main inlet 21, and the pilot valve port 42 communicates with the lower chamber 32. , the branch outlet 43 communicates with the main outlet 22 , and the microvalve 5 controls the pilot valve port 42 ...

Embodiment 2

[0049] The difference of this embodiment is that the expansion valve is a normally closed valve, and when the third microvalve plate is not energized, the flow channel window is connected to the outlet and the orifice; when the third microvalve plate is energized, the flow channel window is connected to the inlet and Orifice, you can change the layout of the inlet, orifice and outlet or change the position of the flow channel window according to the needs. When the flow channel window is connected to the outlet and the orifice, and when the flow channel window is connected to the inlet and the orifice, the flow of refrigerant Flow direction is consistent with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com