Elastic clamping hoop based on viscoelastic polyurethane layer

A polyurethane layer, viscoelastic technology, used in pipeline supports, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problem of limited service life, complex processing, high temperature resistance, corrosion resistance and oil resistance of polymer rubber materials. and other problems, to achieve the effect of changing the support stiffness, improving the overall strength and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

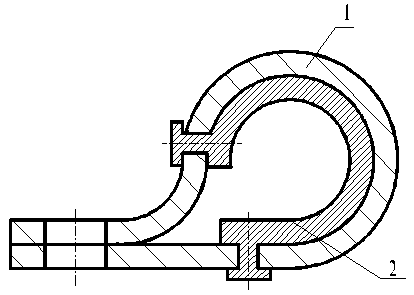

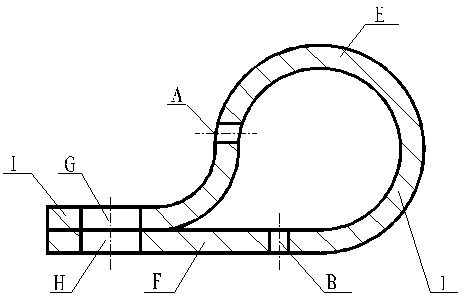

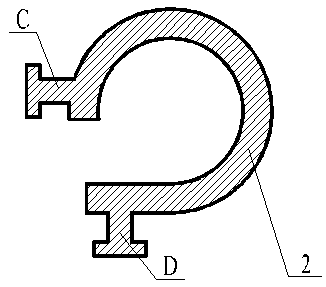

[0031] Referring to the accompanying drawings, an elastic clamp based on a viscoelastic polyurethane layer includes an encircling metal frame 1 and a viscoelastic polyurethane layer liner 2. The encircling metal frame 1 is an integrated structure, and the encircling metal frame 1 Both ends are processed with a first plunger hole A and a second plunger hole B; both ends of the viscoelastic polyurethane layer liner 2 are processed with a raised first plunger C and a second plunger D; A plunger C and a second plunger D are like mushrooms; the first plunger C and the second plunger D protruding from both ends of the viscoelastic polyurethane layer liner 2 and the first plunger hole A of the encircling metal skeleton 1 Cooperating with the second plunger hole B, the viscoelastic polyurethane layer liner 2 is installed on the inner side of the encircling metal framework 1 .

[0032]The encircling metal frame 1 is a long metal plate, and the encircling metal frame 1 is processed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com