micro speaker

A technology of micro-speakers and components, applied in the direction of electrostatic transducer speakers, sensors, electrostatic sensors, etc., can solve the problems of low service life, low vibration reliability of piston connecting rod components, poor acoustic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

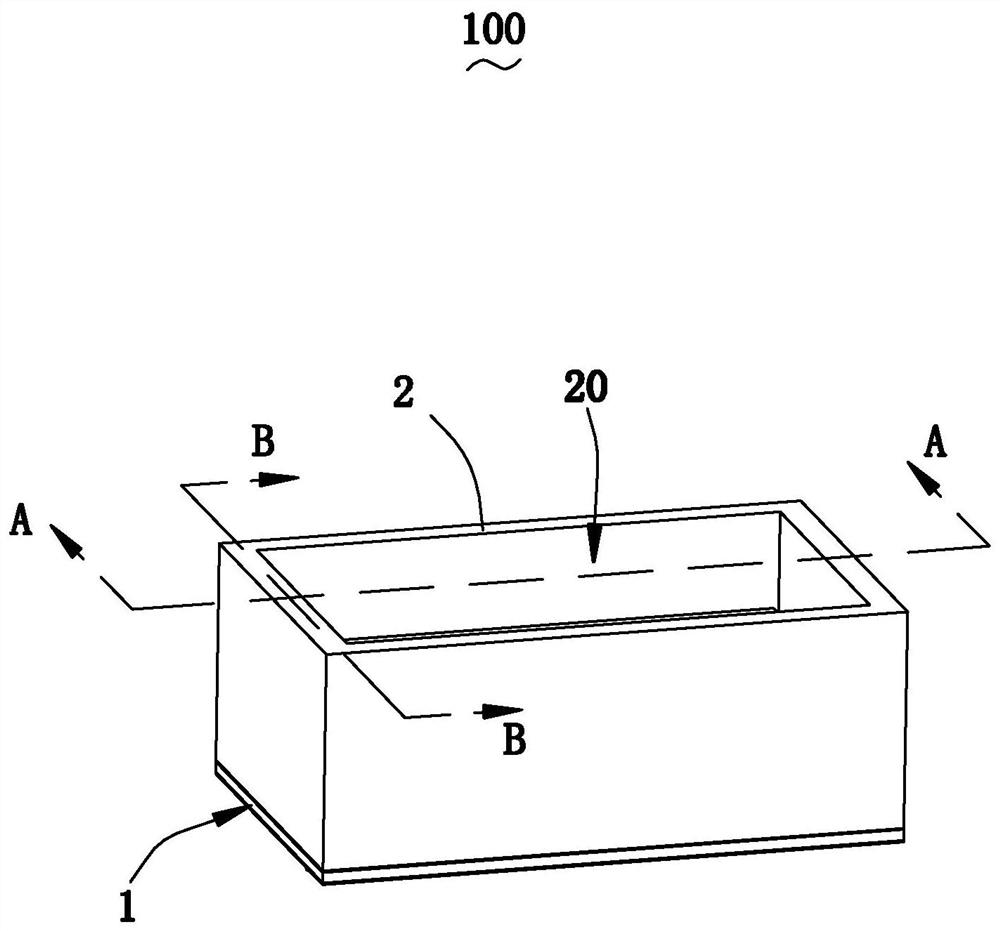

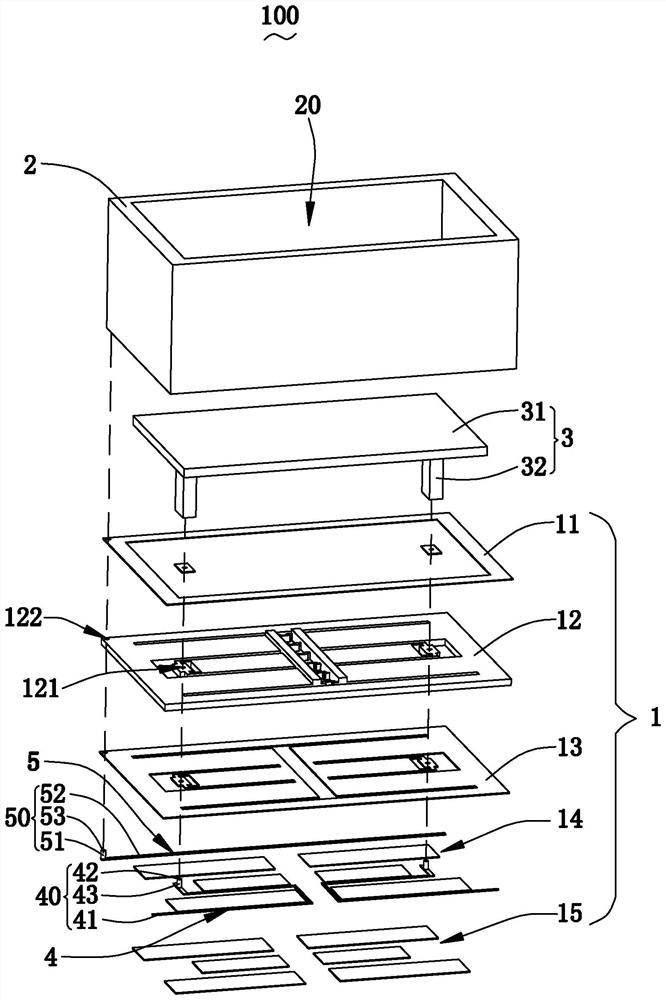

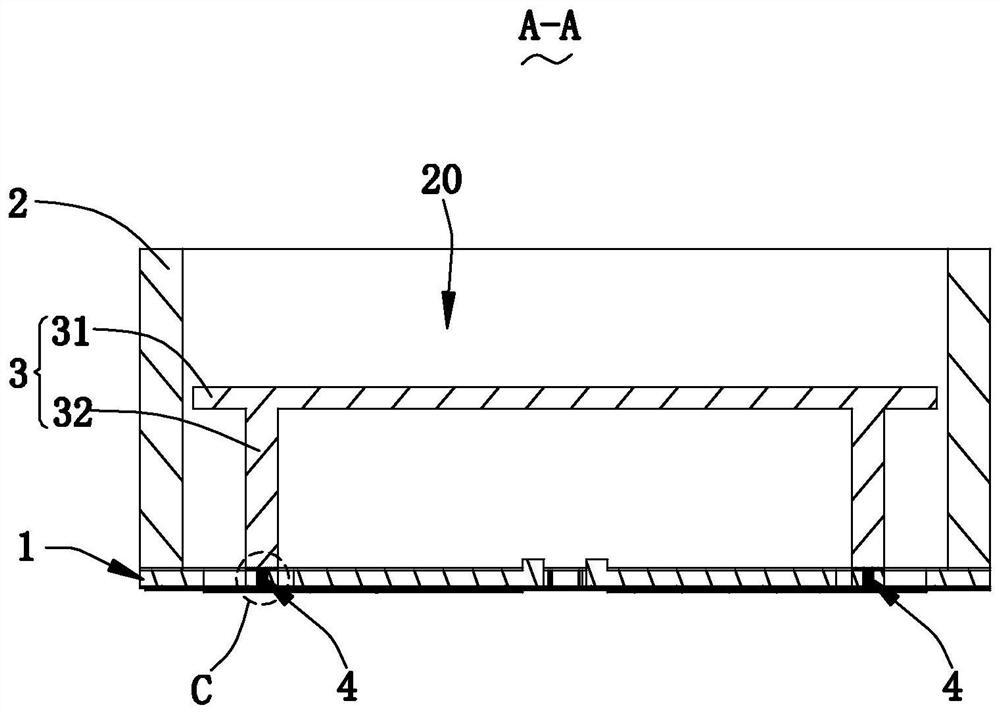

[0039] Please also see Figure 1-7 As shown, the present invention provides a micro-speaker 100 , which includes a driving device 1 , a substrate 2 , a piston rod assembly 3 , a first charge injection device 4 and a second charge injection device 5 .

[0040] The driving device 1 is used to fixedly support the substrate 2 and the piston connecting rod assembly 3 , and the driving device 1 is used to drive the piston connecting rod assembly 3 to vibrate and sound along the thickness direction of the substrate 2 . It is worth mentioning that the driving device 1 is insulated from the piston connecting rod assembly 3 and the substrate 2 respectively.

[0041] It is worth mentioning that the driving method of the driving device 1 includes but not limited to any one of piezoelectric driving, electrostatic driving and electromagnetic driving.

[0042] For example, in this embodiment, the drive device 1 adopts a piezoelectric drive, and more specifically, the drive device 1 includes...

Embodiment approach 2

[0059] see Figure 8 As shown, the microspeaker 100a of the second embodiment is basically the same as the microspeaker of the first embodiment. The structure of the injection device is different. In the microspeaker 100a of the second embodiment, the piezoelectric driver on the piston rod assembly and its peripheral control circuit are used to replace the first charge channel for injecting charge into the piston rod assembly. The following will combine The specific structure is explained:

[0060] The microspeaker 100a includes a driving device 1a, a substrate 2a, a piston rod assembly 3a, a first charge injection device 4a, and a second charge injection device 5a.

[0061] The driving device 1a fixedly supports the piston connecting rod assembly 3a and the substrate 2a, and the driving device 1a is insulated from the piston connecting rod assembly 3a and the substrate 2a respectively, and the driving device 1a uses To drive the piston rod assembly 3a to vibrate and make so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com