Preparation method of metal probe

A technology of metal probes and probes, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of thick probe tips, difficult to corrode again, and increase the cost of probe corrosion devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail

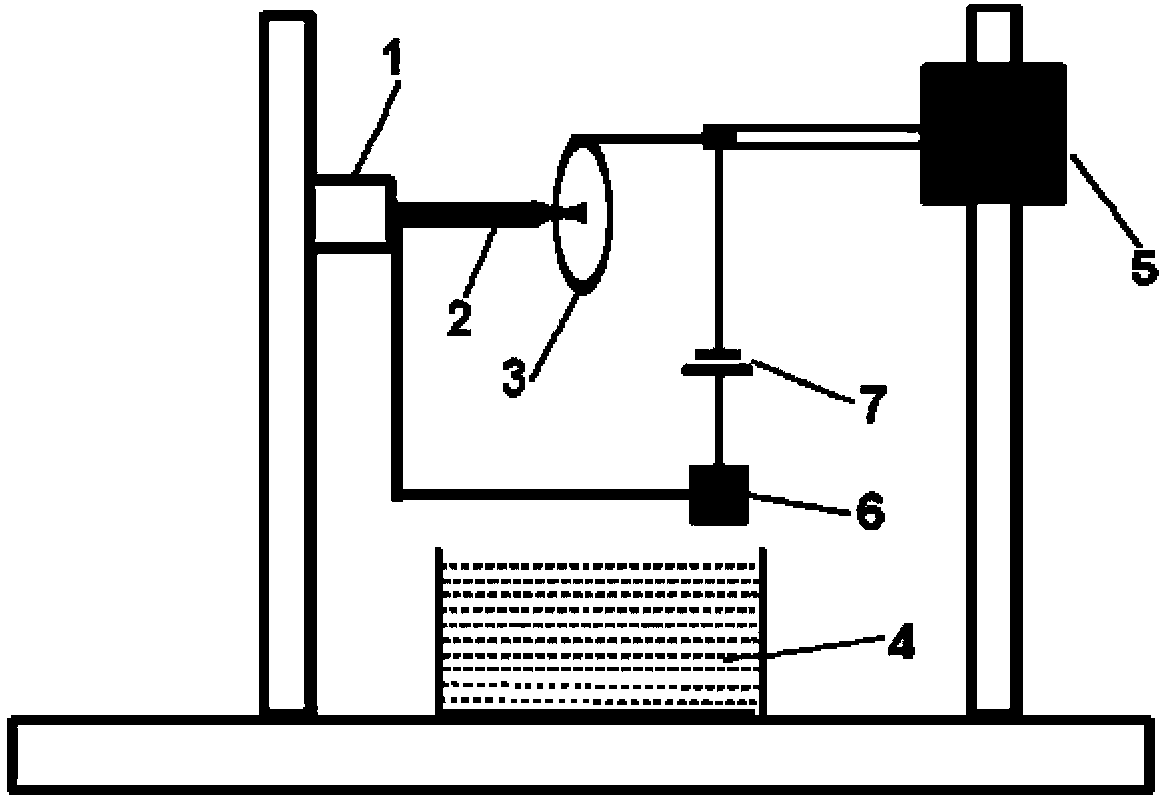

[0010] as attached figure 1 As shown in the needle tip corrosion device, the device includes 1. fixture, 2. metal wire, 3. Pt / Ir alloy ring, 4. corrosion solution, 5. three-dimensional mobile platform, 6. normally-off switch, 7. DC power supply.

[0011] The preparation method is as follows: fix the metal wire (2) to be corroded with a clamp (1) so that the free end of the metal wire (2) is along the horizontal direction; connect the platinum-iridium alloy ring (3) to an adjustable DC power supply ( 7), connect the metal wire (2) to the positive pole of the adjustable DC power supply (7) through the normally open switch (6). And the platinum-iridium alloy ring (3) is fixed on the bracket of the three-dimensional translation platform (7). Wherein, a container (4) containing a corrosive solution is arranged under the platinum-iridium alloy ring (3). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com