Improved thin power inductor manufacturing process

A thin technology of power inductors, applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve problems such as high manufacturing costs, inability to apply production lines, and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The manufacturing process of the improved thin power inductor of the present invention comprises:

[0052] Substrate processing step: use chemical solvents such as methanol or acetone to remove impurities and grease on the surface of the substrate 100, then remove oxides on the surface of the substrate with hydrofluoric acid, and then dehydrate the substrate 100 (Dehydration Bake) (such as figure 1 shown);

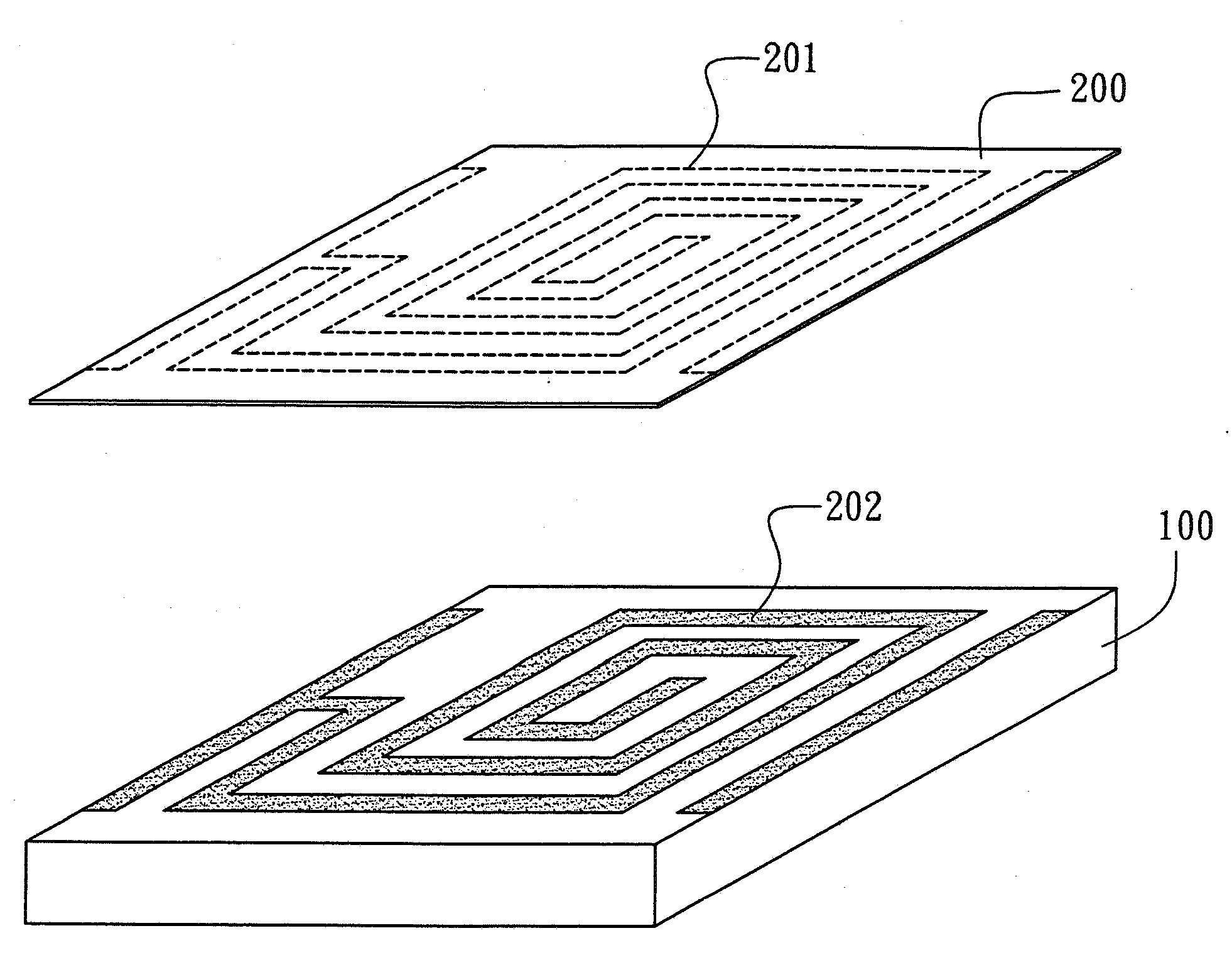

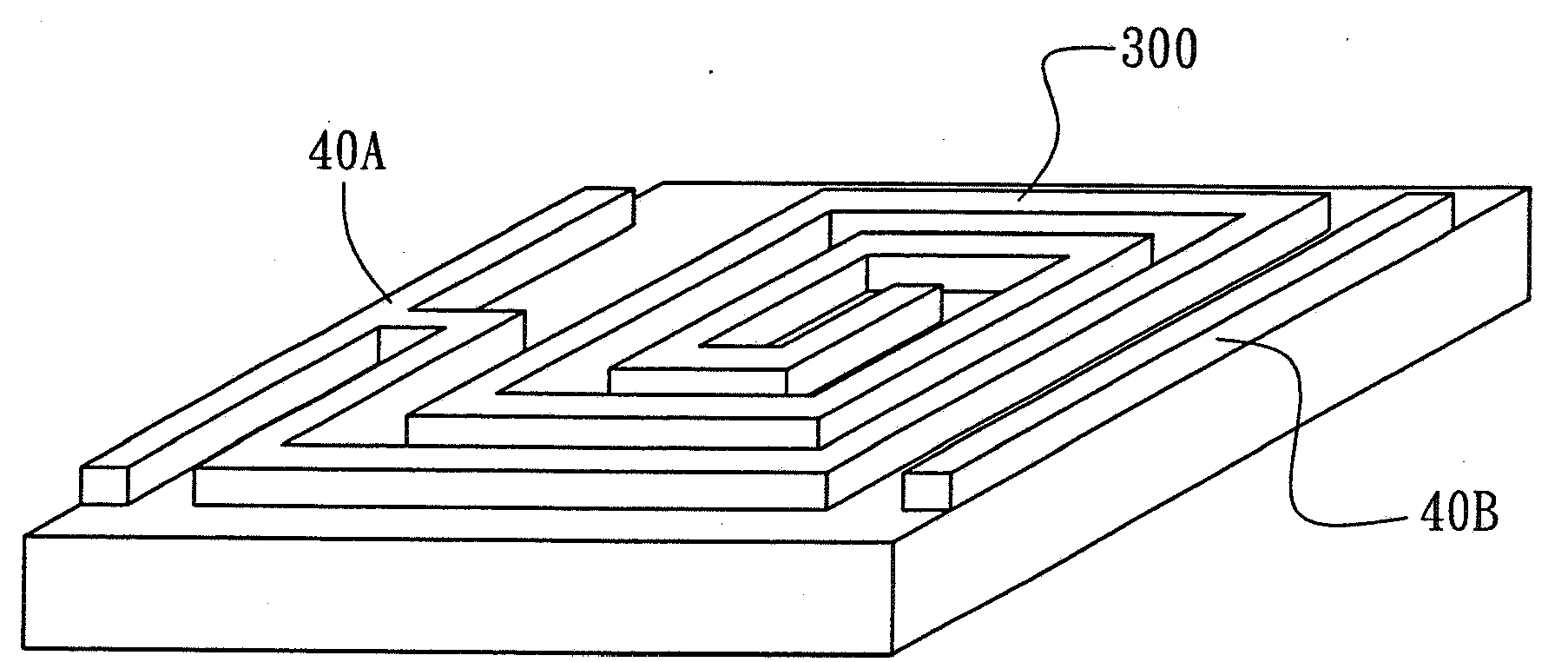

[0053] The step of forming the spiral inductance coil is to place a metal shield 200 with a spiral inductance pattern 201 on the surface above the substrate 100, and to form the spiral inductance coil on the upper surface of the substrate 100 by using a sputtering process and a copper electroplating process Seed layer 202 (such as figure 2 Shown); form the base layer spiral inductance coil 300 and side electrodes 40A, 40B again, and one end of the base layer spiral inductance coil 300 is connected with one side electrode 40A wherein (as image 3 shown);

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com