An ultra-high-speed mechanical switch

A mechanical switch, ultra-high-speed technology, applied in the direction of air switch components, etc., can solve the problems of limited buffering, inability to meet the buffer requirements of ultra-high-speed mechanical switches, damage to the operating mechanism, etc. The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

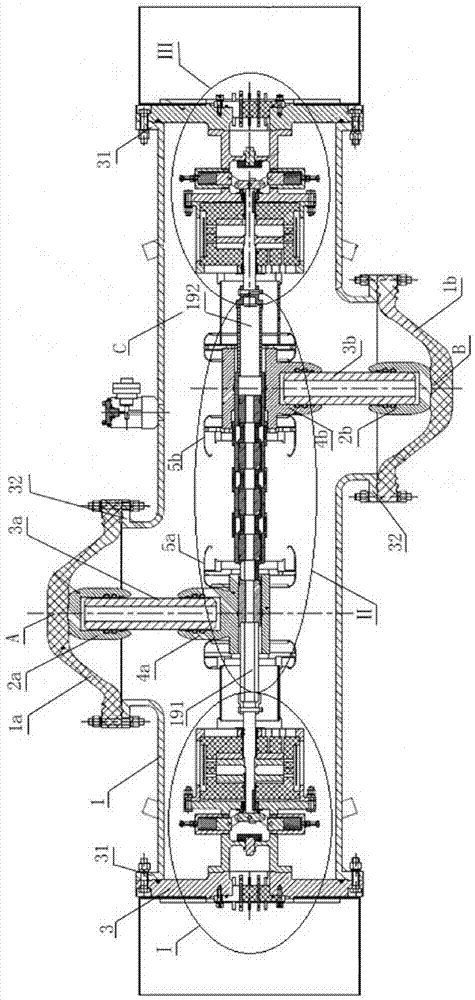

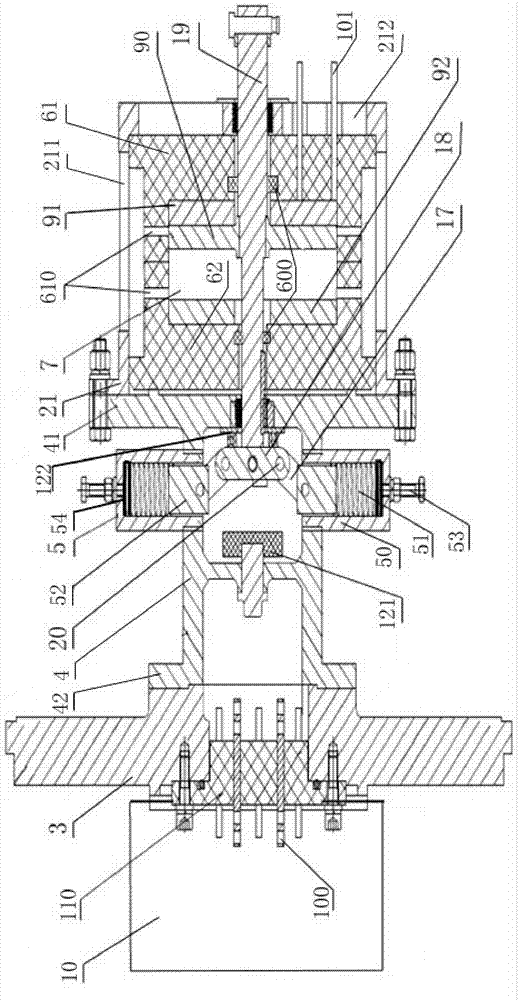

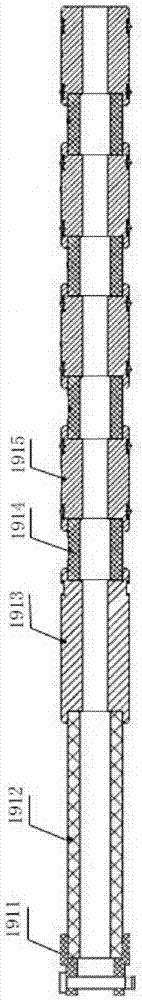

[0030] An embodiment of an ultra-high-speed mechanical switch of the present invention: as Figure 1-6 As shown, it includes a sealed insulating cylinder 1, and the inner space C of the insulating cylinder 1 is filled with high-pressure sulfur hexafluoride gas. and III, the repulsion operating mechanisms I and III are respectively driven and connected with switch pull rods 191 and 192 extending along the axial direction of the insulating cylinder 1, and the two ends of the switch pull rods 191 and 192 are respectively provided with breaking contacts, and the insulating cylinder The outer peripheral wall of the body 1 is respectively sealed and connected with a first conductive end A and a second conductive end B. The first conductive end A and the second conductive end B are located in the same plane passing through the axis of the insulating cylinder and are respectively arranged on the insulating cylinder. 1, the first conductive end A and the second conductive end B are ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com