Fire-extinguisher nozzle, and fire-extinguishing method using same

A technology of nozzles and fire extinguishing sand, which is applied in fire rescue and other fields, and can solve problems such as non-existent and undisclosed nozzle structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiment of the invention

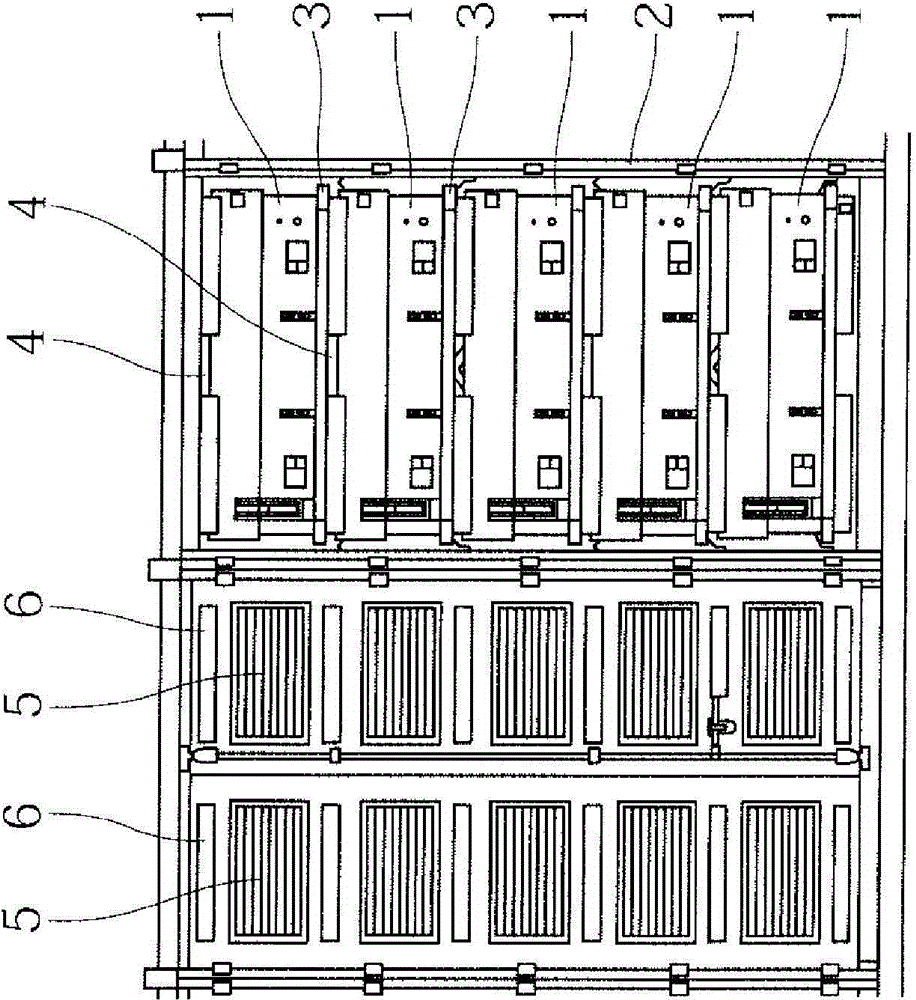

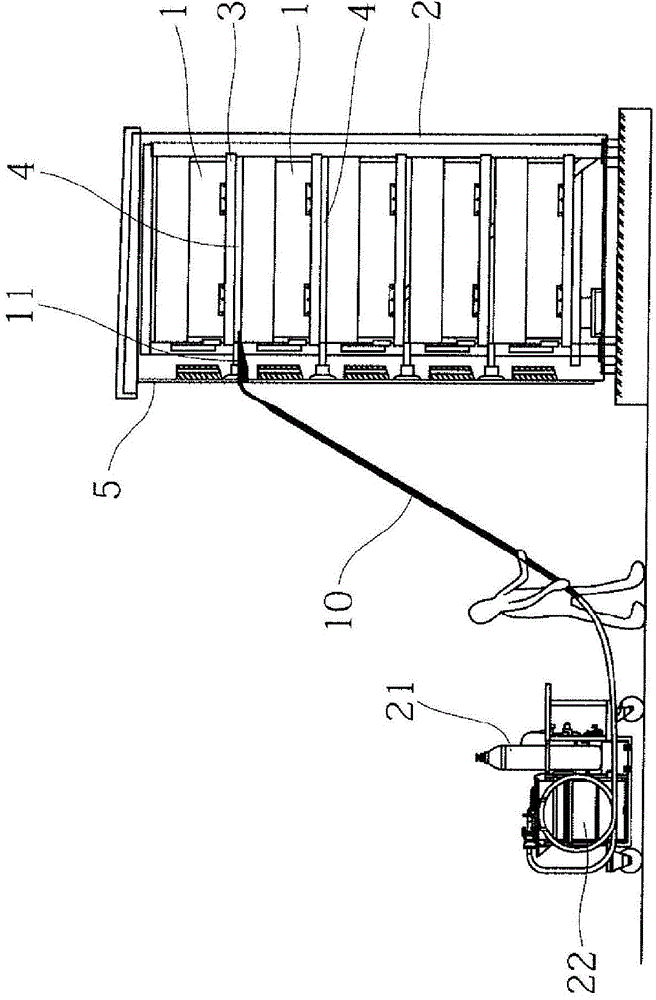

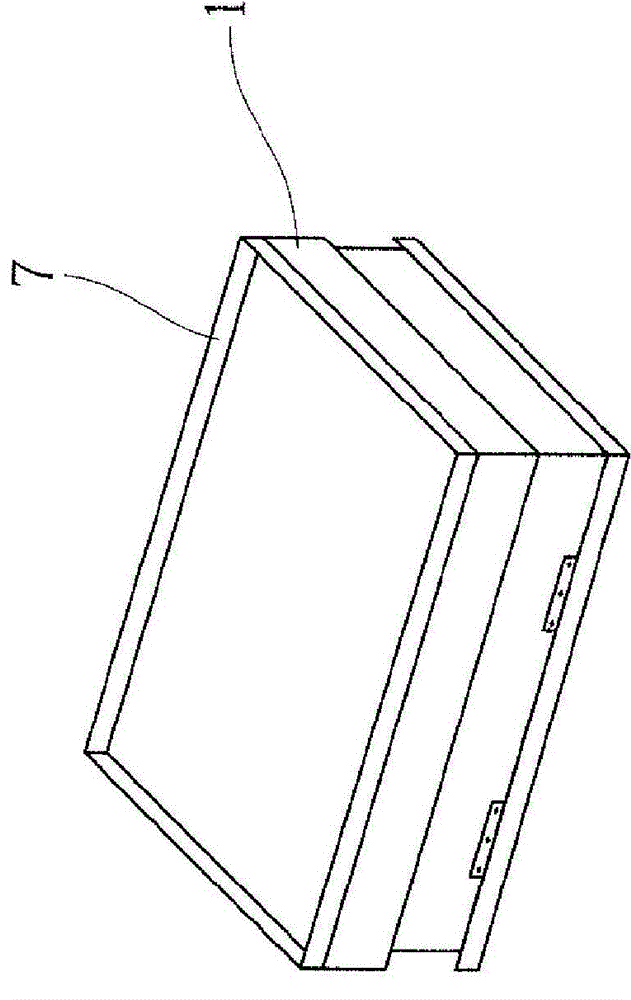

[0028] Preferred embodiments of the present invention are shown below. In the following embodiments, the fire extinguishing object is the charging system of the sodium-sulfur battery, figure 1 is the front view of the charging system for a sodium-sulfur battery, figure 2 is a longitudinal section view, image 3 It is a perspective view of a battery module.

[0029] In these figures, 1 is a battery module, and as described above, the battery module 1 is a member that accommodates a plurality of sodium-sulfur single cells inside a heat insulating container. A charging system for a sodium-sulfur battery is configured by combining a plurality of such battery modules 1 according to the charging capacity. Each of these battery modules 1 is a rectangular parallelepiped with a width and depth of approximately 2 m and a height of approximately 1 m, and is accommodated in a multi-layered manner inside a rack 2 whose entire height is approximatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com