Backpack type field spray sowing machine for raising seedlings with plates

A knapsack type, sprayer technology, applied in the directions of spreader and seeder parts, etc., can solve the problems that rice seeds cannot effectively fall into the seedling tray, affect the uniformity of seed sowing, and poor uniformity of sowing, etc. Simple, uniform and efficient spraying, good seedling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

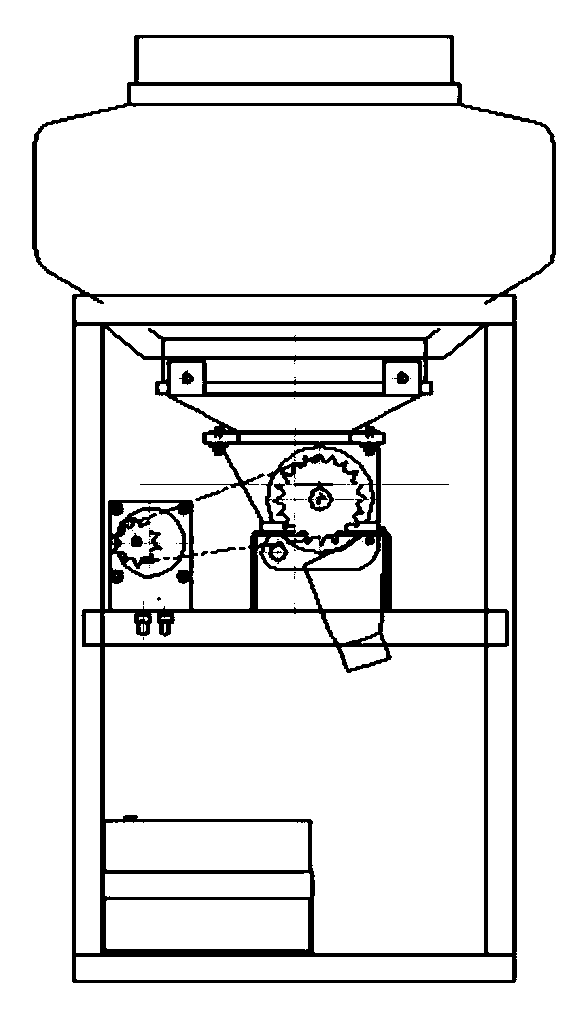

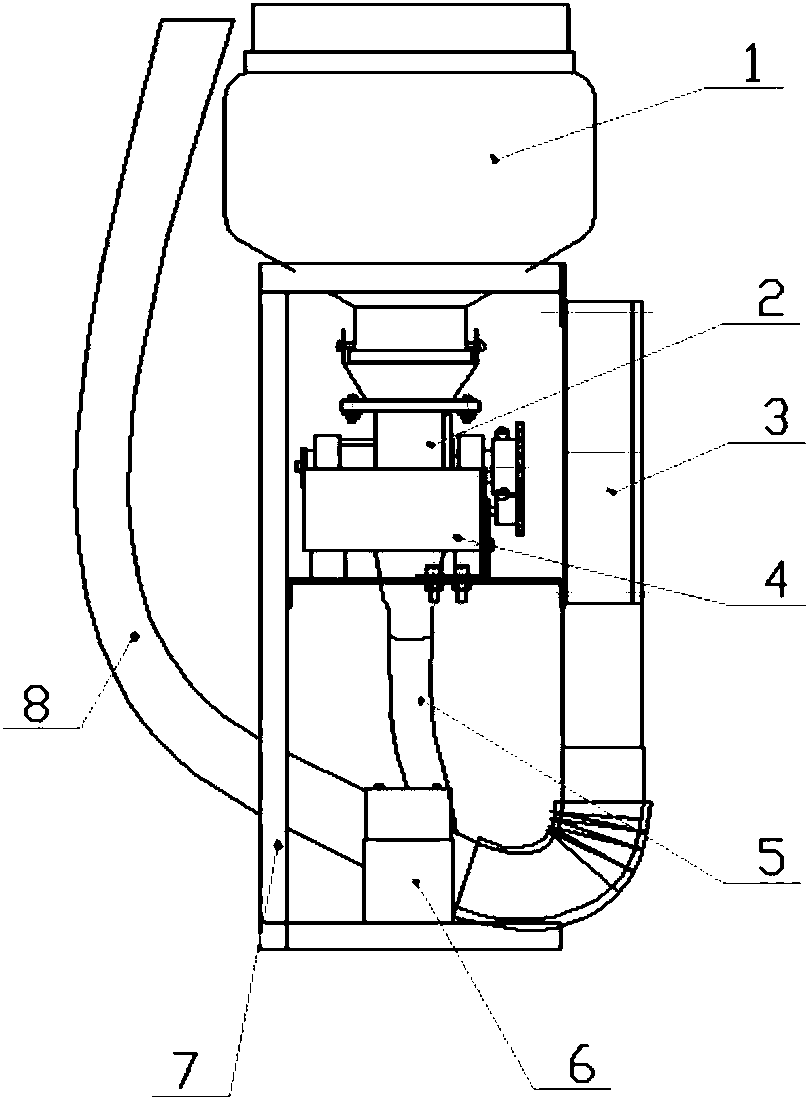

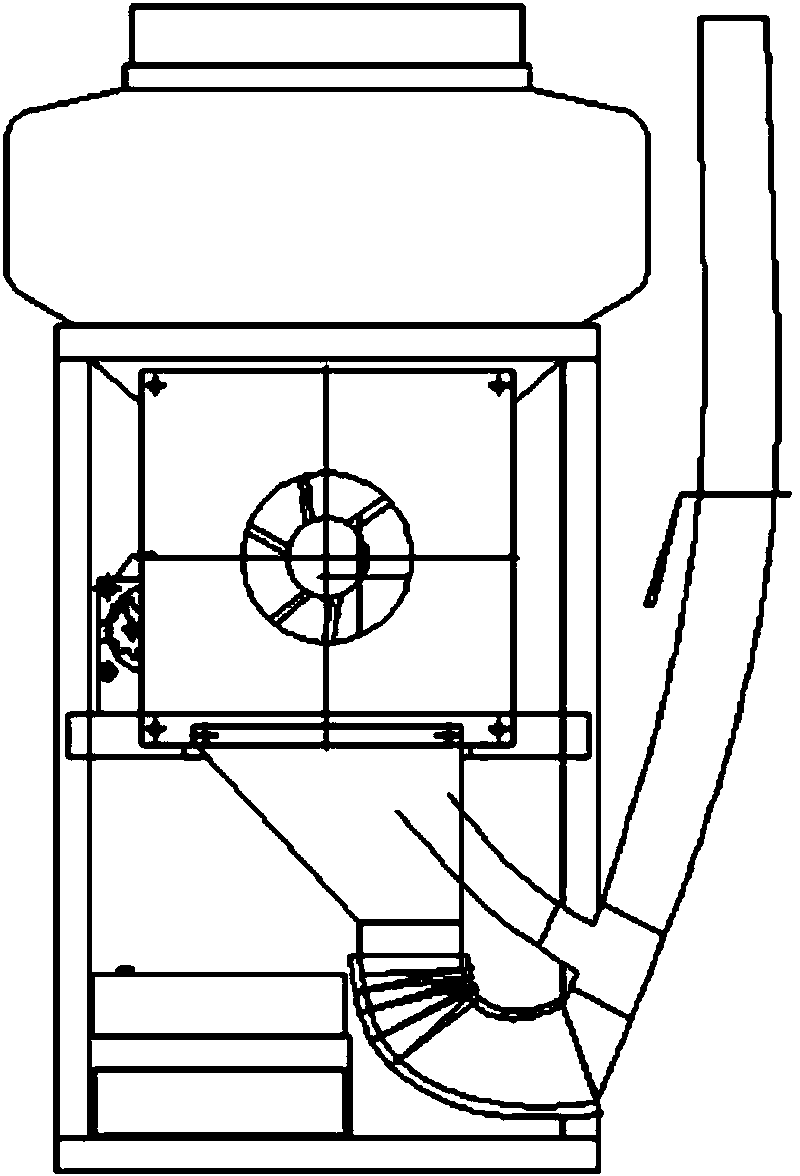

[0022] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0023] see Figure 1-3 , The backpack-type field disc seedling seeding machine is composed of a seed box 1, a seeding mechanism 2, a DC speed-regulating fan 3, a frequency conversion DC motor 4, a seed drop tube 5, a battery 6, a backpack bracket 7, and a spray tube 8. The seed-discharging mechanism 2 is hooked below the seed box 1, and the seeds in the seed-box 1 are discharged into the seed-dropping pipe 5 by the seed-discharging mechanism 2. After mixing with the airflow blown out by the blower fan 3, the way spray tube 8 concentrates on spraying and sowing.

[0024] The air outlet of the speed-regulating fan 3 is connected with the spray tube 8 to control the blowing air volume in the spray tube; the frequency conversion DC motor 4 drives the seed meter shaft to achieve the purpose of controlling the sowing volume. When sowing, load the seeds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com