Cup stand assembly with adjustable inner chamber depth

A cup holder and inner cavity technology, which is applied in the special position of the vehicle, transportation and packaging, vehicle parts, etc., can solve the problems of affecting the rotation of the movable cup holder, difficult to operate, easy to fall into debris, etc., to achieve simple structure and easy operation Convenience, anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A cup holder assembly with adjustable inner cavity depth

[0038] This embodiment is a cup holder assembly with an adjustable inner cavity depth, which is used on the auxiliary instrument panel of an automobile.

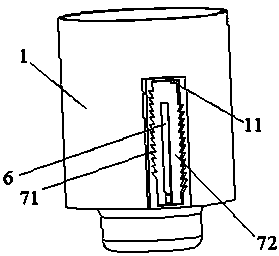

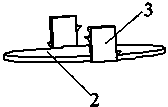

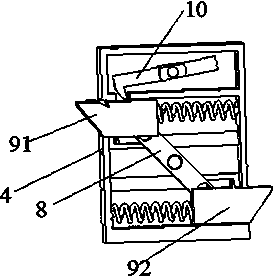

[0039] Such as figure 1 — Figure 5 As shown, it includes a cup holder body 1 with an inner cavity for fixing in the groove on the auxiliary instrument panel of the automobile, and is located in the inner cavity of the cup holder body 1 and slides up and down with the cup holder body 1 by external force. The bottom plate 2, the sliding fit between the cup holder body 1 and the bottom plate 2 can be locked at any matching position.

[0040] The outer wall of the cup holder body 1 is fixed with a slideway extending up and down. The outer wall of the cup holder body is also provided with a through groove 6 extending up and down. A lock housing 3 extending up and down outside the cup holder body 1 . The slideways are symmetrically arranged at two p...

Embodiment 2

[0054] Example 2 A cup holder assembly with adjustable inner cavity depth

[0055] This embodiment has all the structural features of Embodiment 1, and on this basis, a lateral locking elastic element 15 is provided.

[0056] refer to Figure 7 , the lateral locking elastic element 15 is located on the inner wall of the cup holder body 1 at a distance of 1 / 3 from the upper cup mouth, and is an elastic plastic pad-like structure with an air outlet and a cavity, and is glued to the inner wall of the cup holder body 1 fixed. The lateral locking elastic element 15 is symmetrically arranged at two (or three or four) places on the inner wall of the cup holder body 1 in the circumferential direction. The radial rebound force will generate a lateral extrusion force on the water cup, thereby preventing the water cup from shaking left and right or back and forth.

[0057] This embodiment can realize the lateral locking of the container accommodated in the cup holder, so it has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com