Split-type proportional valve

A split type, proportional valve technology, applied in valve details, valve devices, filter separation, etc., can solve the problems of unable to clean the filter screen, filter screen pollution, scrapped proportional valve, etc., to achieve good appearance, ensure normal use, and tightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

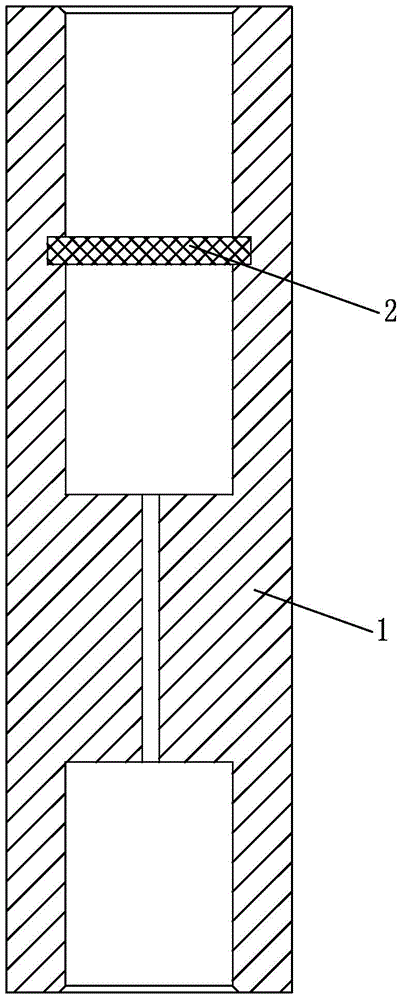

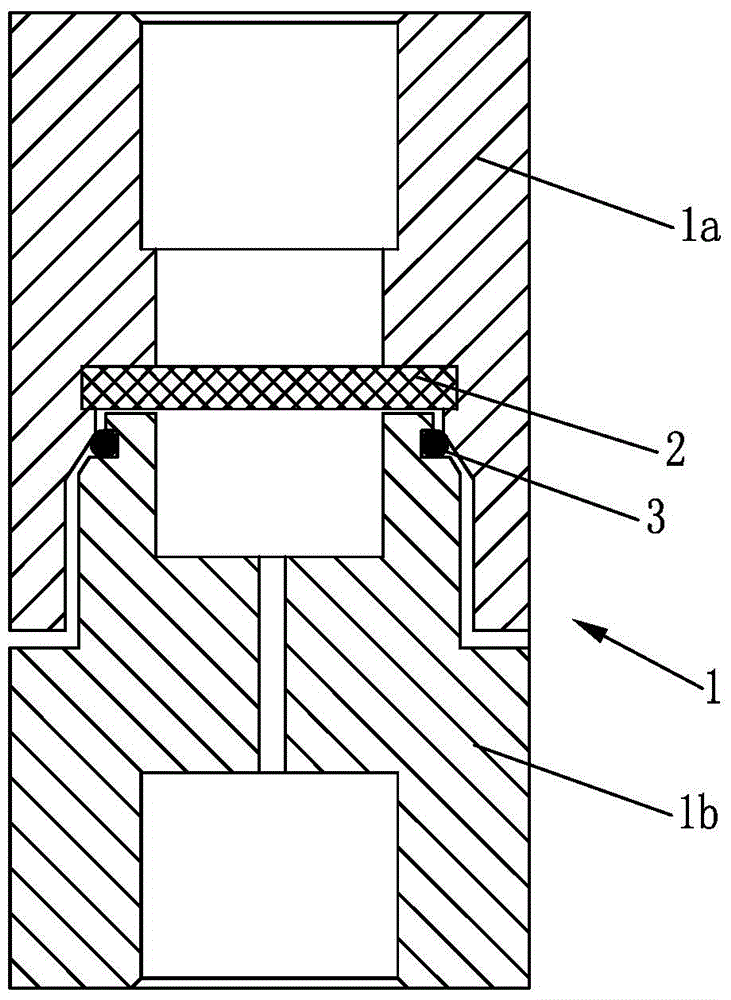

[0016] Such as figure 2 As shown, a split proportional valve is composed of a valve body 1, a filter screen 2 and a sealing ring 3. Wherein, the valve body 1 is a split structure, and is composed of an upper valve body 1a and a lower valve body 1b, and the outer diameters of the upper valve body 1a and the lower valve body 1b are equal, and both are plastic parts. The upper part of the central hole of the upper valve body 1a is an external joint connection section, and the external joint connection section is an internal thread section, and a filter screen 2 is embedded in the middle of the central hole of the upper valve body 1a.

[0017] The central hole of the lower valve body 1b is a two-stage stepped hole with two large ends and a small middle, wherein the diameter section is a flow-limiting section, and the diameter of the flow-limiting section is 1 / 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap