Variable Mach number nozzle for hypersonic low-density wind tunnel

A hypersonic, low-density technology, applied in measurement devices, instruments, aerodynamic tests, etc., can solve the problems of complicated calculation of the three-dimensional profile nozzle profile, complex profile shape, difficult processing, etc., to save research and development costs. , The Mach number has a wide variation range, and the quality of the flow field is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

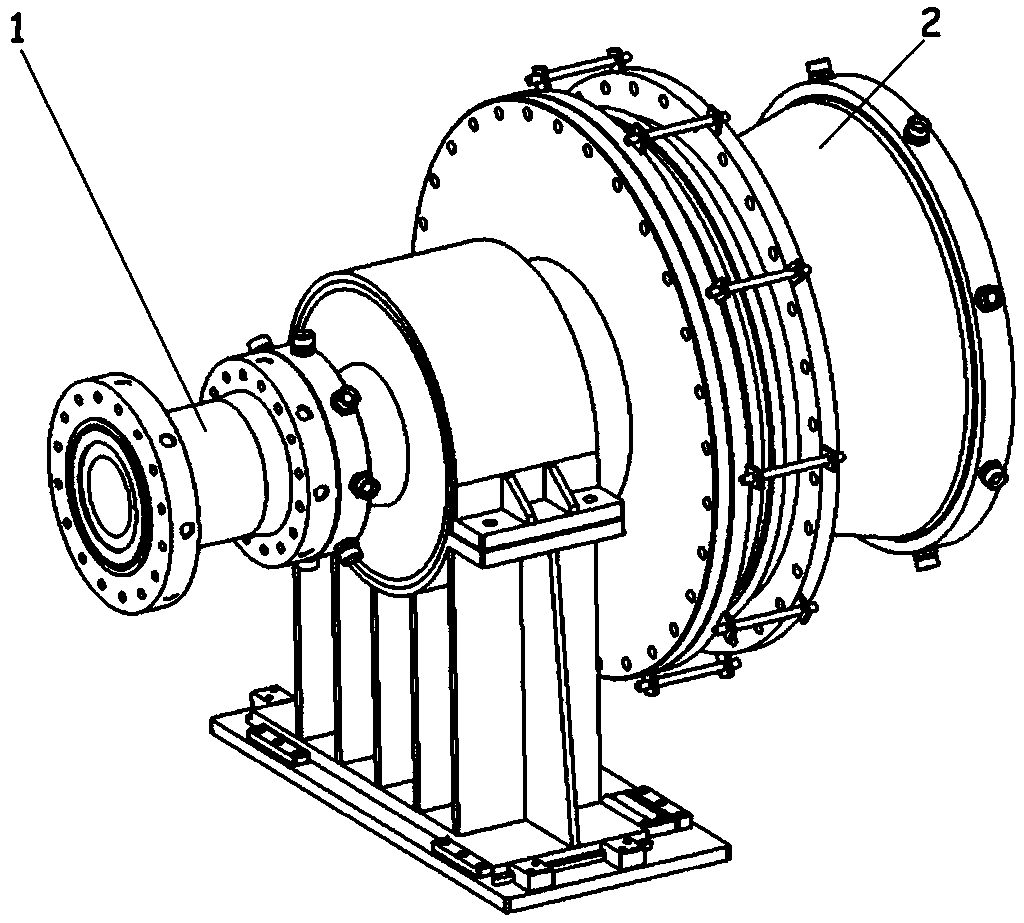

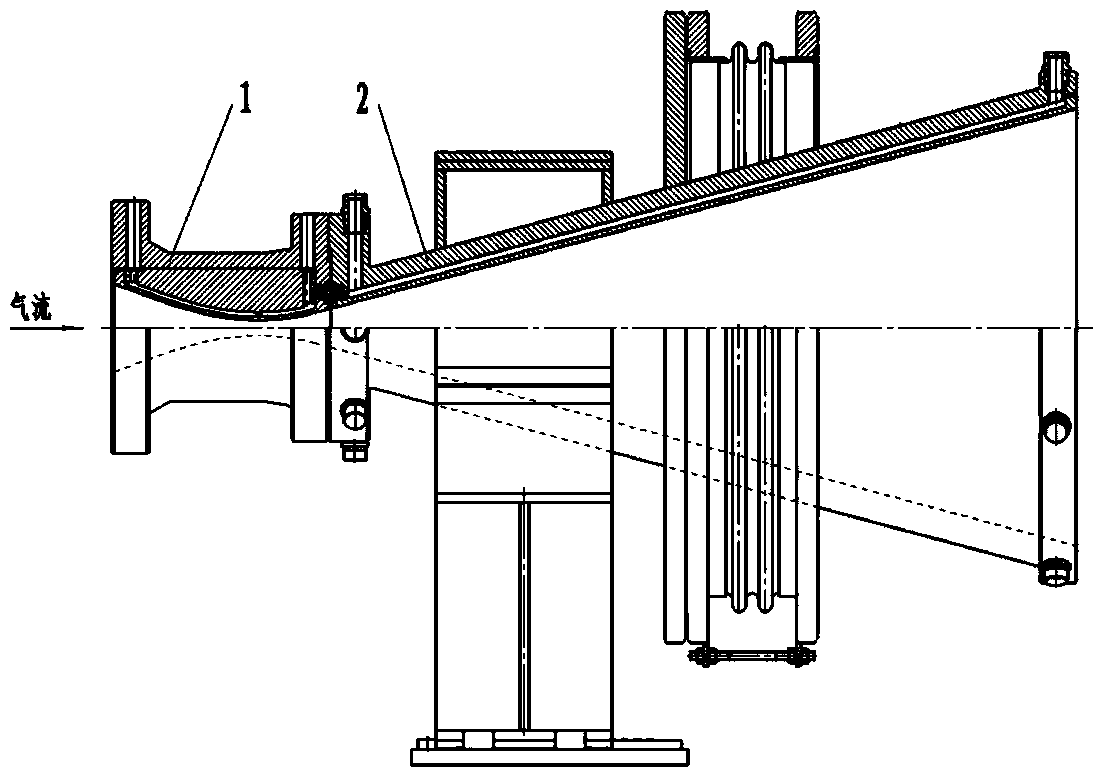

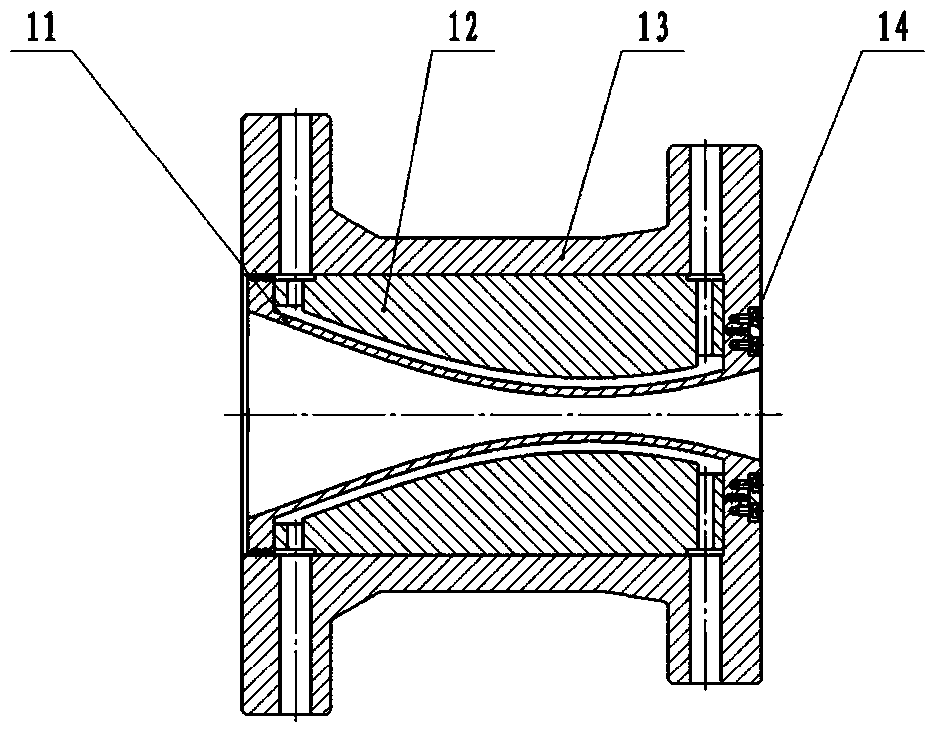

[0017] Such as figure 1 , 2 As shown, the hypersonic low-density wind tunnel variable Mach number nozzle includes a throat section 1 and a diffuser section 2, corresponding to several Mach numbers, there are several throat sections 1, and the diffuser section 2 is shared by several Mach number nozzles . The function of changing the Mach number is realized by replacing the throat section 1. The nozzle is arranged in the wind tunnel building. The front end of the throat section 1 is connected to the front chamber by bolts, and the rear end is connected to the diffuser section 2 by bolts. When replacing the throat section 1, the throat section 1 is caught in the middle, and the lifting and replacement cannot be completed. . Therefore, an expansion joint is installed between the diffusion section 2 and the test section, and a sliding bracket 22 is arranged below the diffusion section 2 . When changing the Mach number of the nozzle to replace the throat section 1, loosen the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com