Splicing screen connection device

A technology for connecting devices and splicing screens, which is used in identification devices, nonlinear optics, instruments, etc., can solve the problems of difficult and large-sized display screens, and the frame width of flat-panel displays, so as to facilitate disassembly and assembly and improve the display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

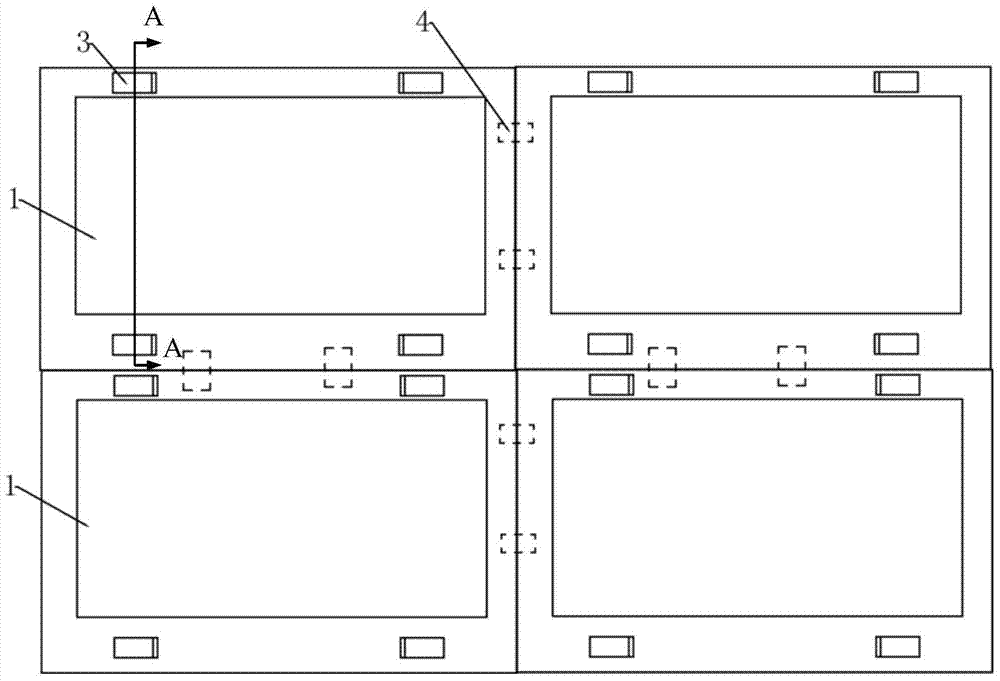

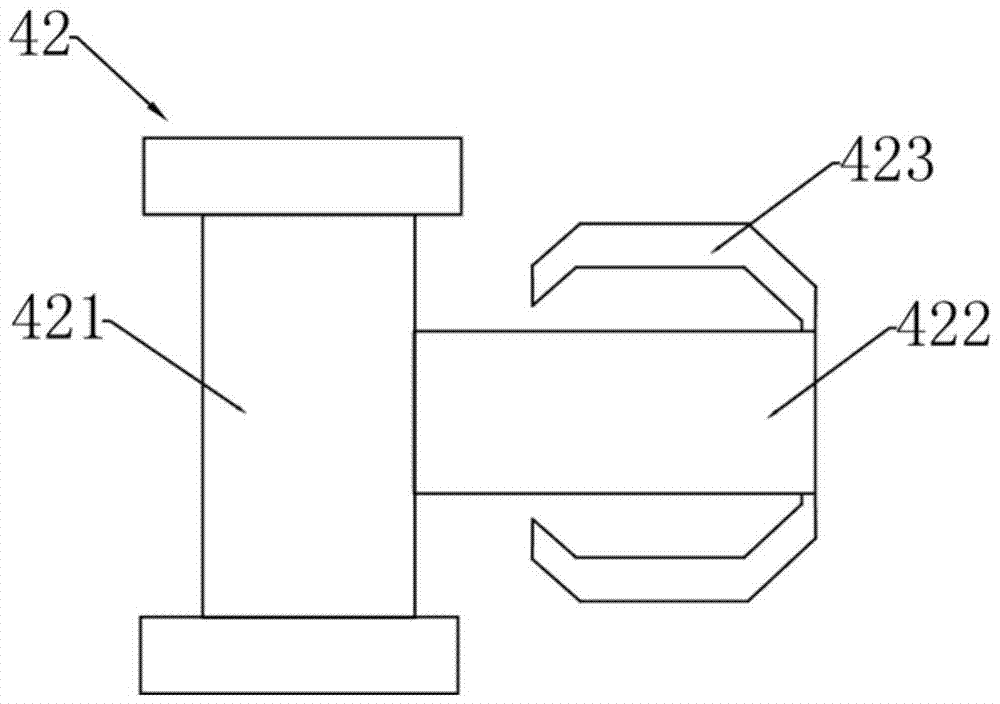

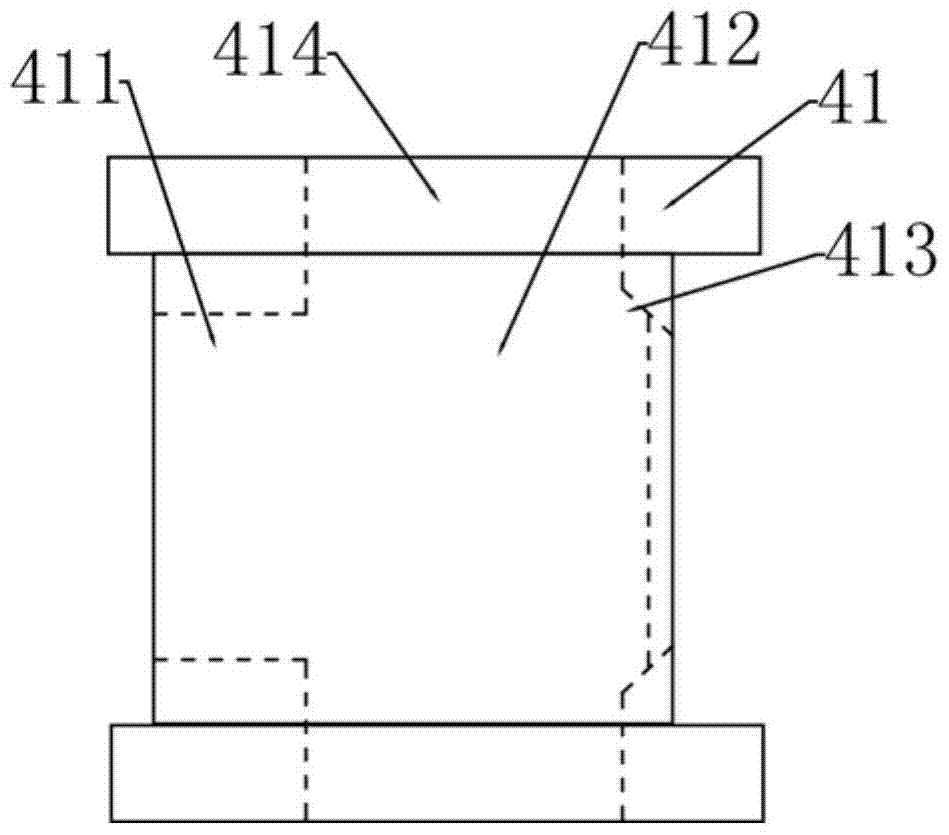

[0018] figure 1 The structure of the splicing screen is shown, and the splicing screen is formed by splicing a plurality of display screens using a connecting device 4 , wherein the display screen includes a liquid crystal panel 1 and a backlight 2 arranged on the back side of the liquid crystal panel 1 . The liquid crystal panel 1 includes a display area and a lead area located on the periphery of the display area, and the lead area is used to lead out the gate lines, data lines, common electrode lines, etc. For driving display, a plurality of via holes are set in the non-wire area of the lead wire area, and the liquid crystal panel 1 is fixedly connected to the backli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com